Abstract

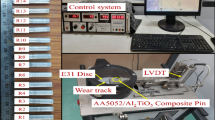

This article deals with the armour grade AA7075-T651 metal matrix nanocomposite reinforced with SiC and Al2O3 nano particles produced by stir casting method. The produced nanocomposite rods are joined without any external source by friction welding process to understand its fatigue and tensile behaviors of its fully deformed zone. The experiments were conducted by using rotating beam fatigue testing machine at different stress levels and the joints characterization were analyzed with various advanced testing machines. The relationship between tensile and fatigue properties of joints were established. Finally, the characteristics of friction welded joint was investigated with the help of scanning electron microscope, optical microscopy analysis under optimized condition.

Similar content being viewed by others

References

Kalkanl A, and Yılmaz S, Mater Des 29 (2008) 775.

Jokhio M H, Panhwar M I, and Unar M A, Mehran Univ Res J Eng Technol 30 (2011) 53.

Veeresh Kumar G B, Rao C S P, Selvaraj N, and Bhagyashekar M S, J Miner Mater Charact Eng 9 (2010) 43.

Wang H, Li G, Zhao Y, and Chen G, Mater Sci Eng A 527 (2010) 2881.

Sahin M, Erol Akata H, and Gulmez T, Mater Charact 58 (2007) 1033.

Vill V I, Friction Welding of Metals, Translated from Russian Publisher, American Welding Society, INC, New York (1962).

Asif Iqbal A K M, Arai Y, and Araki W, Open J Compos Mater 3 (2013) 97.

Ganesh V V, and Chawla N, Metallurg Mater Trans A 34A (2003).

Hochreiter E, Panzenbock M, and Jeglitsch F, Int J Fatigue 15 (1993) 493.

Srivatsan T S, and Al-Hajri M, Compos Part B 33 (2002) 391.

Hashim J, Looney L, and Hashmi M S J, J Mater Process Technol 92 (1999), 1.

Acknowledgments

The authors are grateful to the Chancellor Dr. R. Rangarajan, Vel Tech Dr. Rangarajan and Dr. Sakunthala Technical University, Avadi, Chennai, Tamilnadu, India for the support and facilities provided to carry out this investigation. The authors wish to thank Dr. V. Balasubramanian, Director, CEMAJOR, Department of Manufacturing Engineering, Annamalai University, India for extending the facilities of Metal Joining and Material Testing lab to carry out this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Selvamani, S.T., Vigneshwar, M. & Divagar, S. Establishing the Relationship Between Fatigue and Tensile Strength of Frictionally Joined Metal Matrix Nanocomposite Autogeneous Joints for Aerospace. Trans Indian Inst Met 69, 431–437 (2016). https://doi.org/10.1007/s12666-015-0791-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0791-6