Abstract

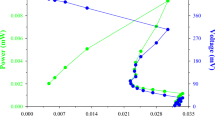

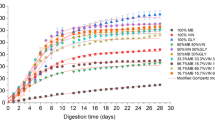

Biohydrogen (bioH2) and soluble metabolites products (SMPs) obtention from the co-digestion process of banana processing wastewater (BPW) and synthetic sewage (SS) were investigated. The reactor performance was evaluated by BPW addition with different initial concentrations: 2.0, 5.0, and 9.6 g of total carbohydrate (TC)/L (pure BPW) using SS to complete the working volume. The dark fermentation process was carried out in a 1 L batch reactor operated at 37 °C/52 h and pH 7. The composition of gas and liquid samples (TC, VFAs, alcohols, and pH) were analyzed during reactor operation. The highest bioH2 production yield (210.82 ± 32.07 NmL/g TC) and bioH2 production rate (40.93 ± 7.60 NmL/g TC/h) were obtained at an initial substrate concentration of 2.0 g TC/L. These results indicated that the co-digestion improved carbohydrate utilization and induced a more effective metabolic pathway to bioH2 production. At this condition, the main soluble metabolite products were acetate and butyrate, whereupon Clostridiacae was the main family involved in BPW fermentation. The prediction of functional gene expression evidenced a shift in the mechanisms of SMPs and bio H2 obtention as the initial concentration of substrate changes.

Graphical Abstract

Similar content being viewed by others

Data Availability

The data that support this paper are available from the corresponding author upon request from readers.

References

Tak, S.S., Shetye, O., Muley, O., Jaiswal, H., Malik, S.N.: Emerging technologies for hydrogen production from wastewater. Int. J. Hydrogen Energy (2022). https://doi.org/10.1016/J.IJHYDENE.2022.06.225

Qyyum, M.A., Ihsanullah, I., Ahmad, R., Ismail, S., Khan, A., Nizami, A.S., Tawfik, A.: Biohydrogen production from real industrial wastewater: Potential bioreactors, challenges in commercialization and future directions. Int. J. Hydrogen Energy (2022). https://doi.org/10.1016/J.IJHYDENE.2022.01.195

Mei, D., Qiu, X., Liu, H., Wu, Q., Yu, S., Xu, L., Zuo, T., Wang, Y.: Progress on methanol reforming technologies for highly efficient hydrogen production and applications. Int. J. Hydrogen Energy (2022). https://doi.org/10.1016/J.IJHYDENE.2022.08.134

Acar, C., Dincer, I.: Review and evaluation of hydrogen production options for better environment. J. Clean Prod. 218, 835–849 (2019). https://doi.org/10.1016/J.JCLEPRO.2019.02.046

Ramprakash, B., Lindblad, P., Eaton-Rye, J.J., Incharoensakdi, A.: Current strategies and future perspectives in biological hydrogen production: a review. Renew. Sustain. Energy Rev. 168, 112773 (2022). https://doi.org/10.1016/J.RSER.2022.112773

Sivaramakrishnan, R., Shanmugam, S., Sekar, M., Mathimani, T., Incharoensakdi, A., Kim, S.H., Parthiban, A., Edwin Geo, V., Brindhadevi, K., Pugazhendhi, A.: Insights on biological hydrogen production routes and potential microorganisms for high hydrogen yield. Fuel 291, 120136 (2021). https://doi.org/10.1016/J.FUEL.2021.120136

Aydin, M.I., Karaca, A.E., Qureshy, A.M.M.I., Dincer, I.: A comparative review on clean hydrogen production from wastewaters. J. Environ. Manag. 279, 111793 (2021). https://doi.org/10.1016/J.JENVMAN.2020.111793

Qadir, M., Drechsel, P., Jiménez Cisneros, B., Kim, Y., Pramanik, A., Mehta, P., Olaniyan, O.: Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum. 44, 40–51 (2020). https://doi.org/10.1111/1477-8947.12187

Caligan, C.J.A., Garcia, M.M.S., Mitra, J.L., San Juan, J.L.G.: Multi-objective optimization for a wastewater treatment plant and sludge-to-energy network. J. Clean Prod. 368, 133047 (2022). https://doi.org/10.1016/J.JCLEPRO.2022.133047

Litti, Y.V., Potekhina, M.A., Zhuravleva, E.A., Vishnyakova, A.V., Gruzdev, D.S., Kovalev, A.A., Kovalev, D.A., Katraeva, I.V., Parshina, S.N.: Dark fermentative hydrogen production from simple sugars and various wastewaters by a newly isolated thermoanaerobacterium thermosaccharolyticum SP-H2. Int. J. Hydrogen Energy (2022). https://doi.org/10.1016/J.IJHYDENE.2022.05.235

Policastro, G., Carraturo, F., Compagnone, M., Guida, M., Fabbricino, M.: Enhancing hydrogen production from winery wastewater through fermentative microbial culture selection. Bioresour. Technol. Rep. (2022). https://doi.org/10.1016/j.biteb.2022.101196

Alvarez, A.J., Fuentes, K.L., Arias, A., Chaparro, C.: Production of hydrogen from beverage wastewater by dark fermentation in an internal circulation reactor: effect on pH and hydraulic retention time. Energy Convers. Manag. X. (2022). https://doi.org/10.1016/J.ECMX.2022.100232

Ziara, R.M.M., Miller, D.N., Subbiah, J., Dvorak, B.I.: Lactate wastewater dark fermentation: the effect of temperature and initial pH on biohydrogen production and microbial community. Int. J. Hydrogen Energy 44, 661–673 (2019). https://doi.org/10.1016/j.ijhydene.2018.11.045

Wadjeam, P., Reungsang, A., Imai, T., Plangklang, P.: Co-digestion of cassava starch wastewater with buffalo dung for bio-hydrogen production. Int. J. Hydrogen Energy 44, 14694–14706 (2019). https://doi.org/10.1016/j.ijhydene.2019.04.138

Manhongo, T.T., Chimphango, A.F.A., Thornley, P., Röder, M.: Current status and opportunities for fruit processing waste biorefineries. Renew. Sustain. Energy Rev. (2022). https://doi.org/10.1016/j.rser.2021.111823

Aurore, G., Parfait, B., Fahrasmane, L.: Bananas, raw materials for making processed food products. Trends Food Sci. Technol. 20, 78–91 (2009). https://doi.org/10.1016/J.TIFS.2008.10.003

Pereira, B.S., de Freitas, C., Vieira, R.M., Brienzo, M.: Brazilian banana, guava, and orange fruit and waste production as a potential biorefinery feedstock. J. Mater. Cycles Waste Manag. 24, 2126–2140 (2022). https://doi.org/10.1007/S10163-022-01495-6/TABLES/3

Rasmeni, Z.Z., Madyira, D.M., Matheri, A.N.: Optimum loading ratio for co-digested wastewater sludge and brewery spent yeast. Energy Rep. 8, 1141–1149 (2022). https://doi.org/10.1016/J.EGYR.2022.06.082

García-Depraect, O., Gómez-Romero, J., León-Becerril, E., López-López, A.: A novel biohydrogen production process: Co-digestion of vinasse and nejayote as complex raw substrates using a robust inoculum. Int. J. Hydrogen Energy 42, 5820–5831 (2017). https://doi.org/10.1016/j.ijhydene.2016.11.204

Yang, G., Hu, Y., Wang, J.: Biohydrogen production from co-fermentation of fallen leaves and sewage sludge. Bioresour. Technol. 285, 121342 (2019). https://doi.org/10.1016/j.biortech.2019.121342

Martín, M.A., de la Rubia, M.A., Martín, A., Borja, R., Montalvo, S., Sánchez, E.: Kinetic evaluation of the psychrophylic anaerobic digestion of synthetic domestic sewage using an upflow filter. Bioresour. Technol. 101, 131–137 (2010). https://doi.org/10.1016/j.biortech.2009.08.010

Wang, J., Wan, W.: Comparison of different pretreatment methods for enriching hydrogen-producing bacteria from digested sludge. Int. J. Hydrogen Energy 33, 2934–2941 (2008). https://doi.org/10.1016/j.ijhydene.2008.03.048

Aquino, S.F., Chernicharo, C.A.L., De, M., Florêncio, L., Santos, D.: Methodologies for determining the specific methanogenic activity (SMA) in anaerobic sludges. San. Environ. Eng. (2007). https://doi.org/10.1590/S1413-41522007000200010

Herbert, D., Phipps, P.J., Strange, R.E.: Chapter III chemical analysis of microbial cells. Methods Microbiol. 5, 209–344 (1971). https://doi.org/10.1016/S0580-9517(08)70641-X

Maintinguer, S.I., Fernandes, B.S., Duarte, I.C.S., Saavedra, N.K., Adorno, M.A.T., Varesche, M.B.: Fermentative hydrogen production by microbial consortium. Int. J. Hydrogen Energy 33, 4309–4317 (2008). https://doi.org/10.1016/j.ijhydene.2008.06.053

Angela, M., Adorno, T., Hirasawa, J.S., Bernadete, M., Varesche, A.: Development and validation of two methods to quantify volatile acids (C2–C6) by GC/FID: headspace (automatic and manual) and liquid-liquid extraction (LLE). Am. J. Analyt Chem. 05, 406–414 (2014). https://doi.org/10.4236/AJAC.2014.57049

Perimenis, A., Nicolay, T., Leclercq, M., Gerin, P.A.: Comparison of the acidogenic and methanogenic potential of agroindustrial residues. Waste Manage 72, 178–185 (2018). https://doi.org/10.1016/J.WASMAN.2017.11.033

APHA: Standard methods for the examination of water and wastewater. American Public Health Association, Washington, D.C. (2005)

Griffiths, R.I., Whiteley, A.S., O’Donnell, A.G., Bailey, M.J.: Rapid method for coextraction of DNA and RNA from natural environments for analysis of ribosomal DNA- and rRNA-based microbial community composition. Appl. Environ. Microbiol. 66, 5488–5491 (2000). https://doi.org/10.1128/AEM.66.12.5488-5491.2000

Callahan, B.J., McMurdie, P.J., Rosen, M.J., Han, A.W., Johnson, A.J.A., Holmes, S.P.: DADA2: high-resolution sample inference from illumina amplicon data. Nat. Methods 13, 7 (2016). https://doi.org/10.1038/nmeth.3869

McLaren, M.R., Callahan, B.J.: Silva 138.1 prokaryotic SSU taxonomic training data formatted for DADA2. Zenodo Database (2021). https://doi.org/10.5281/ZENODO.458795

Kanehisa, M., Goto, S.: KEGG: Kyoto Encyclopedia of genes and genomes. Nucleic Acids Res. 28, 27–30 (2000)

Wang, J., Wan, W.: Kinetic models for fermentative hydrogen production: a review. Green Energy Technol. (2009). https://doi.org/10.1007/978-981-10-4675-9_6

Fangkum, A., Reungsang, A.: Biohydrogen production from sugarcane bagasse hydrolysate by elephant dung: effects of initial pH and substrate concentration. Int. J. Hydrogen Energy 36, 8687–8696 (2011). https://doi.org/10.1016/J.IJHYDENE.2010.05.119

Sivaramakrishna, D., Sreekanth, D., Himabindu, V., Anjaneyulu, Y.: Biological hydrogen production from probiotic wastewater as substrate by selectively enriched anaerobic mixed microflora. Renew. Energy 34, 937–940 (2009). https://doi.org/10.1016/J.RENENE.2008.04.016

Fan, Y.T., Zhang, Y.H., Zhang, S.F., Hou, H.W., Ren, B.Z.: Efficient conversion of wheat straw wastes into biohydrogen gas by cow dung compost. Bioresour. Technol. 97, 500–505 (2006). https://doi.org/10.1016/J.BIORTECH.2005.02.049

Wicher, E., Seifert, K., Zagrodnik, R., Pietrzyk, B., Laniecki, M.: Hydrogen gas production from distillery wastewater by dark fermentation. Int. J. Hydrogen Energy 38, 7767–7773 (2013). https://doi.org/10.1016/j.ijhydene.2013.04.008

Sá, L.R., Cammarota, M.C., Ferreira-Leitão, V.S.: Produção de hidrogênio via fermentação anaeróbia-aspectos gerais e possibilidade de utilização de resíduos agroindustriais brasileiros. Quím. Nova. 37(5), 857–867 (2014). https://doi.org/10.5935/0100-4042.20140138

Lin, C.Y., Lay, C.H., Sen, B., Chu, C.Y., Kumar, G., Chen, C.C., Chang, J.S.: Fermentative hydrogen production from wastewaters: a review and prognosis. Int. J. Hydrogen Energy 37, 15632–15642 (2012). https://doi.org/10.1016/J.IJHYDENE.2012.02.072

Fernandes, B.S., Peixoto, G., Albrecht, F.R., del Saavedra, N.K., Zaiat, M.: Potential to produce biohydrogen from various wastewaters. Energy Sustain. Dev. 14, 143–148 (2010). https://doi.org/10.1016/J.ESD.2010.03.004

García-Depraect, O., Castro-Muñoz, R., Muñoz, R., Rene, E.R., León-Becerril, E., Valdez-Vazquez, I., Kumar, G., Reyes-Alvarado, L.C., Martínez-Mendoza, L.J., Carrillo-Reyes, J., Buitrón, G.: A review on the factors influencing biohydrogen production from lactate: the key to unlocking enhanced dark fermentative processes. Bioresour. Technol. 324, 124595 (2021). https://doi.org/10.1016/J.BIORTECH.2020.124595

Andreani, C.L., Tonello, T.U., Mari, A.G., Leite, L.C.C., Campaña, H.D., Lopes, D.D., Rodrigues, J.A.D., Gomes, S.D.: Impact of operational conditions on development of the hydrogen-producing microbial consortium in an AnSBBR from cassava wastewater rich in lactic acid. Int. J. Hydrogen Energy 44, 1474–1482 (2019). https://doi.org/10.1016/J.IJHYDENE.2018.11.155

Baima Ferreira Freitas, I., Aparecida de Menezes, C., Luiz Silva, E.: An alternative for value aggregation to the sugarcane chain: biohydrogen and volatile fatty acids production from sugarcane molasses in mesophilic expanded granular sludge bed reactors. Fuel 260, 116419 (2020). https://doi.org/10.1016/J.FUEL.2019.116419

Matsumoto, M., Nishimura, Y.: Hydrogen production by fermentation using acetic acid and lactic acid. J. Biosci. Bioeng. 103, 236–241 (2007). https://doi.org/10.1263/JBB.103.236

Kim, T.H., Lee, Y., Chang, K.H., Hwang, S.J.: Effects of initial lactic acid concentration, HRTs, and OLRs on bio-hydrogen production from lactate-type fermentation. Bioresour. Technol. 103, 136–141 (2012). https://doi.org/10.1016/J.BIORTECH.2011.09.093

Fuess, L.T., Ferraz, A.D.N., Machado, C.B., Zaiat, M.: Temporal dynamics and metabolic correlation between lactate-producing and hydrogen-producing bacteria in sugarcane vinasse dark fermentation: the key role of lactate. Bioresour. Technol. 247, 426–433 (2018). https://doi.org/10.1016/J.BIORTECH.2017.09.121

Villa Montoya, A.C., Cristina da Silva Mazareli, R., Delforno, T.P., Centurion, V.B., Sakamoto, I.K., Maia de Oliveira, V., Silva, E.L., Amâncio Varesche, M.B.: Hydrogen, alcohols and volatile fatty acids from the co-digestion of coffee waste (coffee pulp, husk, and processing wastewater) by applying autochthonous microorganisms. Int. J. Hydrogen Energy 44, 21434–21450 (2019). https://doi.org/10.1016/J.IJHYDENE.2019.06.115

Xu, R., Yang, Z.H., Zheng, Y., Zhang, H.B., Liu, J.B., Xiong, W.P., Zhang, Y.R., Ahmad, K.: Depth-resolved microbial community analyses in the anaerobic co-digester of dewatered sewage sludge with food waste. Bioresour. Technol. 244, 824–835 (2017). https://doi.org/10.1016/J.BIORTECH.2017.07.056

Yang, G., Wang, J.: Changes in microbial community structure during dark fermentative hydrogen production. Int. J. Hydrogen Energy 44, 25542–25550 (2019). https://doi.org/10.1016/J.IJHYDENE.2019.08.039

Yang, G., Wang, J.: Biohydrogen production by co-fermentation of antibiotic fermentation residue and fallen leaves: insights into the microbial community and functional genes. Bioresour. Technol. 337, 125380 (2021). https://doi.org/10.1016/J.BIORTECH.2021.125380

Hallenbeck, P.C.: Fermentative hydrogen production: principles, progress, and prognosis. Int. J. Hydrogen Energy 34, 7379–7389 (2009). https://doi.org/10.1016/j.ijhydene.2008.12.080

Yin, Y., Wang, J.: Predictive functional profiling of microbial communities in fermentative hydrogen production system using PICRUSt. Int. J. Hydrogen Energy 46, 3716–3725 (2021). https://doi.org/10.1016/J.IJHYDENE.2020.10.246

Hallenbeck, P.C.: Fundamentals of the fermentative production of hydrogen. Water Sci. Technol. 52, 21–29 (2005)

Funding

The financial assistance was provided by São Paulo Research Foundation (FAPESP), Grant No. 2020/15155-3.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by CCCF, as well as the written of the first draft of the manuscript. CF performed the High-Performance Liquid Chromatography analysis. DFCM contributed to the experimental outline and discussion. SIM and MB made funding acquisition, advising and discussion. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

da Costa Freire, C.C., Marin, D.F.C., da Silva Mazareli, R.C. et al. Unravelling the Biohydrogen Production Potential from a Co-Digestion Process of Banana Processing Wastewater and Synthetic Sewage by Anaerobic Fermentation: Performance Evaluation and Microbial Community Analysis. Waste Biomass Valor 15, 1587–1601 (2024). https://doi.org/10.1007/s12649-023-02258-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02258-6