Abstract

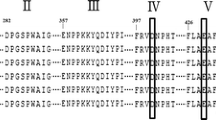

α-Amylase is the major biocatalyst involved in saccharification process of starch-based biofuel production. Most of the α-amylases reported in literature are not stable and catalytically active in presence of metabolites (biosolvents, and bioacids), and other media components such as salts and reducing agents, hence starch-based biofuels are produced by two-step process of separate hydrolysis by α-amylase, and later the fermentation of biofuel production. Finding new α-amylase with special properties can assist to integrate the process of saccharification and biofuel fermentation. We report a new α-amylase produced from wild type Bacillus strain IBT108. This α-amylase (10.5 U/ml) can be produced from wheat bran (5%) based medium. It can be purified by diethylaminoethyl weak anion exchange-based fast protein liquid chromatography. Purified α-amylase has molecular mass of 68 kDa with a high specific activity (734.8 U/mg), and significant Vmax (1428.6 U/mg) and Km (2.8 mg/ml). Protein fingerprinting analysis reveals that it is a unique member of super-families of AmyAc and MaltAmyC which can act on both α-1,4 and α-1,6-glycosidic linkages of starch. It shows optimal activity at pH 7 and 70 °C, retains 72–92% of its activity in acidic pH range between 4 and 6.5, and stable at 60 °C for 2 h. Notably, it is resistant to 5 mM concentration of urea, dithiothreitol, β-mercaptoethanol, surfactants and EDTA, also shows > 70% of its activity in presence of 1 M solvents. Consequently, adding this α-amylase (2.5–3 U/ml) assists Clostridia to effectively utilize 375 g/l waste potato, and produce high concentration of butanol (20.41–23.74 g/l) and hydrogen (3.20–4.38 l/l).

Graphic Abstract

Similar content being viewed by others

References

Enzymes, B.: Global Biofuel Enzymes Industry. https://prnewswire.com/news-releases/global-biofuel-enzymes-industry-300671711 (2018). Accessed 20 May 2019

Novozymes: Liquozyme®: Fewer chemicals. More yield. https://novozymes.com/en/advance-your-business/bioenergy/Liquozyme (2019). Accessed 10 Aug 2019

Enzymes, N.: Biofuel and bioenergy, thermostable alpha amylase. https://enzyme-india.com/amylase-enzymes-biofuel (2015). Accessed 20 May 2019

Virunanon, C., Ouephanit, C., Burapatana, V., Chulalaksananukul, W.: Cassava pulp enzymatic hydrolysis process as a preliminary step in bio-alcohols production from waste starchy resources. J. Clean. Prod. 39, 273–279 (2013)

Li, H.G., Ma, X.X., Zhang, Q.H., Luo, W., Wu, Y.Q., Li, X.H.: Enhanced butanol production by solvent tolerance Clostridium acetobutylicum SE25 from cassava flour in a fibrous bed bioreactor. Bioresour. Technol. 221, 412–418 (2016)

Li, X., Li, Z., Zheng, J., Shi, Z., Li, L.: Yeast extract promotes phase shift of bio-butanol fermentation by Clostridium acetobutylicum ATCC824 using cassava as substrate. Bioresour. Technol. 125, 43–51 (2012)

Sharma, A., Satyanarayana, T.: Microbial acid-stable α-amylases: characteristics, genetic engineering and applications. Process Biochem. 48(2), 201–211 (2013)

Van der Maarel, M.J.E.C., van der Veen, B., Uitdehaag, J.C.M., Leemhuis, H., Dijkhuizen, L.: Properties and applications of starch-converting enzymes of the α-amylase family. J. Biotechnol. 94(2), 137–155 (2002)

Liu, Y.H., Lu, F.P., Li, Y., Yin, X.B., Wang, Y., Gao, C.: Characterisation of mutagenised acid-resistant alpha-amylase expressed in Bacillus subtilis WB600. Appl. Microbiol. Biotechnol. 78(1), 85–94 (2008)

Arikan, B.: Highly thermostable, thermophilic, alkaline, SDS and chelator resistant amylase from a thermophilic Bacillus sp. isolate A3-15. Bioresour. Technol. 99(8), 3071–3076 (2008)

Asoodeh, A., Chamani, J., Lagzian, M.: A novel thermostable, acidophilic α-amylase from a new thermophilic “Bacillus sp. Ferdowsicous” isolated from Ferdows hot mineral spring in Iran: purification and biochemical characterization. Int. J. Biol. Macromol. 46(3), 289–297 (2010)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31(3), 426–428 (1959)

Rajagopalan, G., He, J., Yang, K.L.: Production, purification, and characterization of α-amylase from solventogenic Clostridium sp. BOH3. Bioenergy Res. 7(1), 132–141 (2014)

Rajagopalan, G., He, J., Yang, K.L.: A highly efficient NADH-dependent butanol dehydrogenase from high-butanol-producing Clostridium sp. BOH3. Bioenergy Res. 6(1), 240–251 (2013)

Paquet, V., Croux, C., Goma, G., Soucaille, P.: Purification and characterization of the extracellular alpha-amylase from Clostridium acetobutylicum ATCC 824. Appl. Environ. Microbiol. 57(1), 212–218 (1991)

Abernathy, D.G., Spedding, G., Starcher, B.: Analysis of protein and total usable nitrogen in beer and wine using a microwell ninhydrin assay. J. Inst. Brew. 115(2), 122–127 (2009)

Shirazi, O.U., Khattak, M.M.A.K., Shukri, N.A.: Quantitative analysis of minerals in the selected formulations of spices and herbs using ICP-MS. Prog. Nutr. 18, 161–165 (2016)

Rajagopalan, G., He, J., Yang, K.L.: Direct fermentation of xylan by Clostridium strain BOH3 for the production of butanol and hydrogen using optimized culture medium. Bioresour. Technol. 154, 38–43 (2014)

Burton, K.: A study of the conditions and mechanism of the diphenylamine reaction for the colorimetric estimation of deoxyribonucleic acid. Biochem. J. 62(2), 315–323 (1956)

Rajagopalan, G., Krishnan, C.: Optimization of agro-residual medium for α-amylase production from a hyper-producing Bacillus subtilis KCC103 in submerged fermentation. J. Chem. Technol. Biotechnol. 84(4), 618–625 (2009)

Tiwari, S., Shukla, N., Mishra, P., Gaur, R.: Enhanced production and characterization of a solvent stable amylase from solvent tolerant Bacillus tequilensis RG-01: thermostable and surfactant resistant. Sci. World J. 2014, 972763 (2014)

Burhan, A., Nisa, U., Gökhan, C., Ömer, C., Ashabil, A., Osman, G.: Enzymatic properties of a novel thermostable, thermophilic, alkaline and chelator resistant amylase from an alkaliphilic Bacillus sp. isolate ANT-6. Process Biochem. 38(10), 1397–1403 (2003)

Abdel-Fattah, Y., Soliman, N., El-Toukhy, N., El-Gendi, H., Ahmed, R.: Production, purification, and characterization of thermostable α-amylase produced by Bacillus licheniformis isolate AI20. J. Chem. 2013, 11 (2012)

Asoodeh, A., Alemi, A., Heydari, A., Akbari, J.: Purification and biochemical characterization of an acidophilic amylase from a newly isolated Bacillus sp. DR90. Extremophiles 17, 339–348 (2013)

Asoodeh, A., Emtenani, S., Emtenani, S., Jalal, R., Housaindokht, M.R.: Molecular cloning and biochemical characterization of a thermoacidophilic, organic-solvent tolerant α-amylase from a Bacillus strain in Escherichia coli. J. Mol. Catal. B 99, 114–120 (2014)

Bernhardsdotter, E., Garriott, O., Pusey, M.: Enzymic properties of an alkaline chelator-resistant α-amylase from an alkaliphilic Bacillus sp. isolate L1711. Process Biochem. 40, 2401–2408 (2005)

Hagihara, H., Igarashi, K., Hayashi, Y., Endo, K., Ikawa-Kitayama, K., Ozaki, K., Kawai, S., Ito, S.: Novel alpha-amylase that is highly resistant to chelating reagents and chemical oxidants from the alkaliphilic Bacillus isolate KSM-K38. Appl. Environ. Microbiol. 67(4), 1744–1750 (2001)

Kalpana, B.J., Pandian, S.K.: Halotolerant, acid-alkali stable, chelator resistant and raw starch digesting alpha-amylase from a marine bacterium Bacillus subtilis S8–18. J. Basic Microbiol. 54(8), 802–811 (2014)

Mamo, G., Gessesse, A.: Purification and characterization of two raw-starch-digesting thermostable α-amylases from a thermophilic Bacillus. Enzyme Microb. Technol. 25(3), 433–438 (1999)

Sajedi, R.H., Naderi-Manesh, H., Khajeh, K., Ahmadvand, R., Ranjbar, B., Asoodeh, A., Moradian, F.: A Ca-independent α-amylase that is active and stable at low pH from the Bacillus sp. KR-8104. Enzyme Microb. Technol. 36(5), 666–671 (2005)

Nagarajan, D.R., Rajagopalan, G., Krishnan, C.: Purification and characterization of a maltooligosaccharide-forming α-amylase from a new Bacillus subtilis KCC103. Appl. Microbiol. Biotechnol. 73(3), 591–597 (2006)

Emtenani, S., Asoodeh, A., Emtenani, S.: Gene cloning and characterization of a thermostable organic-tolerant α-amylase from Bacillus subtilis DR8806. Int. J. Biol. Macromol. 72, 290–298 (2015)

Dheeran, P., Kumar, S., Jaiswal, Y.K., Adhikari, D.K.: Characterization of hyperthermostable alpha-amylase from Geobacillus sp. IIPTN. Appl. Microbiol. Biotechnol. 86(6), 1857–1866 (2010)

Liu, B., Wang, Y., Zhang, X.: Characterization of a recombinant maltogenic amylase from deep sea thermophilic Bacillus sp. WPD616. Enzyme Microb. Technol. 39(4), 805–810 (2006)

Mitchell, W.J.: Carbohydrate uptake and utilization by Clostridium beijerinckii NCIMB 8052. Anaerobe 2(6), 379–384 (1996)

Mitchell, W.J.: The phosphotransferase system in solventogenic Clostridia. J. Mol. Microbiol. Biotechnol. 25(2–3), 129–142 (2015)

Moon, H.G., Jang, Y.S., Cho, C., Lee, J., Binkley, R., Lee, S.Y.: One hundred years of clostridial butanol fermentation. FEMS Microbiol. Lett. 363(3), 1–15 (2016)

METACYC: A member of the BioCyc database collection. https://metacyc.org (2020). Accessed 26 Feb 2020

FAOSTAT: Food and Agriculture Organization of the United Nations https://fao.org (2019). Accessed 10 Aug 2019.

Potatopro: Food Innovation online crop https://potatopro.com (2019). Accessed 5 Mar 2019

Nimcevic, D., Schuster, M., Gapes, J.R.: Solvent production by Clostridium beijerinckii NRRL B592 growing on different potato media. Appl. Microbiol. Biotechnol. 50(4), 426–428 (1998)

Acknowledgements

This work was supported by the Science and Engineering Research Board, Department of Science and Technology, Government of India (ECR/2016/000722); and Faculty Startup Grant (FSG/2016/108) from SAU, New Delhi, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahato, R.K., Fatema, I.T. & Rajagopalan, G. Thermostable, Solvent, Surfactant, Reducing Agent and Chelator Resistant α-Amylase from Bacillus Strain IBT108: A Suitable Candidate Enables One-Step Fermentation of Waste Potato for High Butanol and Hydrogen Production. Waste Biomass Valor 12, 223–238 (2021). https://doi.org/10.1007/s12649-020-01017-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01017-1