Abstract

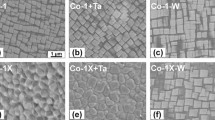

Solvent refining with Al-Si alloy is a promising purification method for the production of solar-grade silicon (SoG-Si) feedstock owing to the advantages of low production cost and high impurity removal efficiency. In this process, larger refined Si primary dendrites should be easily collected after acid leaching, which is favorable to recovery, thereby reducing the production cost. Hence, the growth behavior of the precipitated Si crystal must be investigated systematically. In the present work, the morphology evolution of solidified Al-Si alloys with a wide range of Si content (30 ~ 70 wt%) was analyzed. The typical plate-like Si primary dendrites grown following the twin plane re-entrance edge (TPRE) mechanism formed in all alloy compositions. As increasing the Si content from 30 wt% to 50 wt%, the Si primary dendrites underwent a coarsening process attributed to the preferred growth along with < 211 > and < 111 > directions, leading to an increase in the experimental recovery rate. However, the preferred growth along < 211 > direction was inhibited when the Si content is higher than 55 wt%. Moreover, the broken effect originating from grain collision and thermal stress on the Si primary dendrites was enhanced by further increasing the Si content, resulting in a decrease in the experimental recovery rate. Therefore, the optimum composition is determined as Al-50 ~ 55 wt% Si for solvent refining solution, based on the cost reduction consideration.

Similar content being viewed by others

Data Availability

Not applicable.

References

Chigondo F (2018) From metallurgical-grade to solar-grade silicon: an overview. Silicon 10:789–798

Johnston MD, Khajavi LT, Li M, Sokhanvaran S, Barati M (2012) High-temperature refining of metallurgical-grade silicon: a review. JOM 64:935–945

Zhang L, Tan Y, Li J, Liu Y, Wang D (2013) Study of boron removal from molten silicon by slag refining under atmosphere. Mat Sci Semicon Proc 16:1645–1649

Wang J, Li X, He Y, Feng N, An X, Teng F, Cao C, Zhao C, Zhang Z, Xie E (2013) Purification of metallurgical grade silicon by a microwave-assisted plasma process. Sep Purif Technol 102:82–85

Li S, Deng XC, Zhang C, Wen JH, Wu JJ, Wei KX, Ma WH (2020) Leaching behavior of impurities in metallurgical grade silicon subjected to electromagnetic strengthening. J Alloy Compd 831:154888

Lv GQ, Bao Y, Zhang YF, He YF, Ma WH, Lei Y (2018) Effects of electromagnetic directional solidification conditions on the separation of primary silicon from Al-Si alloy with high Si content. Mat Sci Semicon Proc 81:139–148

Yoshikawa T, Morita K (2012) An evolving method for solar-grade silicon production: solvent refining. JOM 64:946–951

Yoshikawa T, Morita K (2009) Refining of silicon during its solidification from a Si-Al melt. J Cryst Growth 311:776–779

Mitrasinovic AM, Utigard TA (2009) Refining silicon for solar cell application by copper alloying. Silicon 1:239–248

Kita K, Wen C, Otomo J, Yamada K, Komiyama H, Takahashi H (2002) Study on the lateral growth of silicon films from metal solutions with temperature gradient. J Cryst Growth 234:153–158

Li YL, Chen J, Dai SY (2016) Effect of iron addition (up to 10000ppmw) on silicon purification during Al-Si solvent refining. J Cryst Growth 453:49–53

Khajavi LT, Morita K, Yoshikawa T, Barati M (2015) Removal of Boron from silicon by solvent refining using Ferrosillicon alloys. Metall Mater Trans B 46(2):615–620

Khajavi LT, Morita K, Yoshikawa T, Barati M (2015) Thermodynamics of boron distribution in solvent refining of silicon using ferrosilicon alloys. J Alloy Compd 619:634–638

Lai HX, Sheng ZL, Li JT, Xing PF, Luo XT (2018) Enhanced separation of phosphorus from metallurgical grade silicon by CaAl2Si2 phase reconstruction. Sep Purif Technol 191:257–265

Ren YS, Wang HP, Morita K (2018) Growth control and enrichment of Si crystals from Si-Sn melt by directional solidification. Vacuum 158:86–92

Ma XD, Yoshikawa T, Morita K (2015) Purification of metallurgical grade Si combining Si-Sn solvent refining with slag treatment. Sep Purif Technol 125:264–268

Chen H, Morit K, Ma XD, Chen ZY, Wang Y (2019) Boron removal for solar-grade silicon production by metallurgical route: A review. Sol Energ Mat Sol C 203:110169

Lei Y, Sun L, Ma WH, Wei KX, Morita K (2016) Enhancing B removal from Si with small amounts of Ti in electromagnetic solidification refining with Al-Si alloy. J Alloy Compd 666:406–411

Gökçe A, Findik F, Kurt AO (2013) Effects of Mg content on aging behavior of Al4CuXMg PM alloy. Mater Design 46:524–531

Gökçe A, Findik F, Kurt AO (2011) Microstructural examination and properties of premixed Al-Cu-Mg powder metallurgy alloy. Mater Charact 67(7):730–735

Gökçe A, Findik F, Kurt AO (2016) Sintering and aging behaviors of Al4CuXMg PM alloy. Can Metall Quart 55(4):391–401

Yoshikawa T, Morita K (2007) Continuous solidification of Si from Si-Al melt under the induction heating. ISIJ Int 47:582–584

Li JY, Wang L, Ni P, Tan Y (2017) Growth of bulk Si from Si-Al alloy by temperature gradient zone melting. Mat Sci Semicon Proc 66:170–175

Seo KH, Jeon JB, Uoun JW, Kim SJ, Kim KY (2016) Recycling of Al-Si die casting scraps for solar Si feedstock. J Cryst Growth 442:1–7

Lei Y, Ma WH, Sun L, Wu JJ, Dai YN, Marita K (2016) Removal of B from Si by Hf addition during Al-Si solvent refining process. Sci Technol Adv Mat 17(1):12–19

Yoshikawa T, Arimura K, Morita K (2005) Boron removal by titanium addition in solidification refining of silicon with Si-Al melt. Metall Mater Trans B 36:837–842

Li YL, Ban BY, Li JW, Zhang TT, Bai XL, Chen J, Dai SY (2015) Effect of cooling rate on phosphorus removal during Al-Si solvent refining. Metall Mater Trans B 46B:542–544

Esfahani S, Barati M (2011) Purification of metallurgical silicon using iron as an impurity getter part I: Growth and separation of Si. Met Mater Int 17(5):823–829

Li JW, Guo ZC, Li JC (2015) Super gravity separation of purified Si from solvent refining with the Al-Si alloy system for solar grade silicon. Silicon 7(3):239–246

Li JW, Guo ZC, Tang HQ (2012) Si purification by solidification of Al-Si melt with super gravity. T Nonferr Metal Soc 22:958–963

Li JY, Liu Y, Tan Y, Li YQ, Zhang L, Wu SR, Jia PJ (2013) Effect of tin addition on primary silicon recovery in Si-Al melt during solidification refining of silicon. J Cryst Growth 37:1–6

Kim KY, Jeon JB, Shin S (2014) Centrifugal separation of primary silicon crystal in solvent refining of silicon using Al-30 %Si alloy. Cryst Res Technol 49(10):761–767

Mohammad W, Ullah, Carlberg T (2011) Silicon crystal morphologies during solidification refining from Al-Si melts. J Cryst Growth 318:212–218

Gumaste JL, Mohanty BC, Galgali RK, Syamaprasad U, Nayak BB, Singh SK, Jena PK (1987) Solvent refining of metallurgical grade silicon. Sol Energ Mater 16:289–296

Bai XL, Ban BY, Li JW, Fu ZQ, Peng ZJ, Wang CB, Chen J (2018) Segregation behavior of metal impurities during Al-Si melt directional solidification with an open ended crucible. Silicon 10(4):1283–1290

Chiang CH, Tsao Chi YA (2005) Si coarsening of spray-formed high loading hypereutectic Al-Si alloys in the semisolid state. Mat Sci Eeg A-Struct 396:263–270

Yu ZY, Fu X, Zhu J (2014) Revisiting the twin plane re-entrant edge growth mechanism at an atomic scale by electron microscopy. Cryst Growth Des 14:4411–4417

Acknowledgements

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China (Grant No. 51741205) and the Key Technology R&D Program of Ningxia Hui Autonomous Region (Grant No. 201502).

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51741205) and the Key Technology R&D Program of Ningxia Hui Autonomous Region (Grant No. 201502).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Mangmang Gao, Xu Zhao, and Ang Gao. The first draft of the manuscript was written by Mangmang Gao and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of Interest/Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to Participate

All authors happily agree to participate in this research study.

Consent for Publication

All authors permit the permission to the journal to publish this research study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, M., Zhao, X., Gao, A. et al. Effect of Si Content on the Morphology Evolution of the Si Primary Dendrites in Al-Si Alloy Solvent Refining Process. Silicon 14, 4501–4508 (2022). https://doi.org/10.1007/s12633-021-01233-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01233-x