Abstract

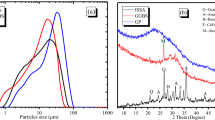

Industrial solid waste (ISW)—cement blends have the advantages of low carbon, low energy consumption, and low pollution, but their clinker replacement level in low carbon cement is generally low. To address this challenge, this study considers the latest progress and development trends in the ISW—cement blend research, focusing on the activation of ISWs, the formation of ISW—cement blends, and their associated hydration mechanisms. After the mechanical activation of ISWs, the D50 (average size) typically drops below 10 µm, and the specific surface area increases above 350 m2/kg. Thermal activation can increase the glassy-phase content and reactivity of ISWs, where the coal gangue activation temperature is usually set at 400–1000°C. Furthermore, the roles of ISWs in the hydration of ISW—cement blends are divided into physical and chemical roles. The physical action of ISWs usually acts in the early stage of the hydration of ISW—cement blends. Subsequently, ISWs participate in the hydration reaction of ISW—cement blends to generate products, such as C—(A)—S—H gels. Moreover, alkali activation affects the hydration kinetics of ISW—cement blends and modifies the proportion of gels. Environmental impacts and costs of ISW—cement blends have also been discussed to guide stakeholders in selecting sustainable ISWs.

Similar content being viewed by others

References

United States Geological Survey, Cement, United States Geological Survey, Reston [2021-11-23]. https://www.usgs.gov/centers/national-minerals-information-center/cement-statistics-and-information

E. Benhelal, E. Shamsaei, and M.I. Rashid, Challenges against CO2 abatement strategies in cement industry: A review, J. Environ. Sci., 104(2021), p. 84.

P. Friedlingstein, M. O’Sullivan, M.W. Jones, et al., Global carbon budget 2020, Earth Syst. Sci. Data, 12(2020), No. 4, p. 3269.

R.M. Andrew, Global CO2 emissions from cement production, Earth Syst. Sci. Data, 10(2018), No. 1, p. 195.

C. Miao, L.X. Liang, F. Zhang, et al., Review of the fabrication and application of porous materials from silicon-rich industrial solid waste, Int. J. Miner. Metall. Mater., 29(2022), No. 3, p. 424.

T. Hemalatha and A. Ramaswamy, A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete, J. Clean. Prod., 147(2017), p. 546.

G. Xu and X.M. Shi, Characteristics and applications of fly ash as a sustainable construction material: A state-of-the-art review, Resour. Conserv. Recycl., 136(2018), p. 95.

Z. Hussain, N. Chang, J.Q. Sun, et al., Modification of coal fly ash and its use as low-cost adsorbent for the removal of directive, acid and reactive dyes, J. Hazard. Mater., 422(2022), art. No. 126778.

J.J. Zhang, X.Y. Zhang, B. Liu, et al., Phase evolution and properties of glass ceramic foams prepared by bottom ash, fly ash and pickling sludge, Int. J. Miner. Metall. Mater., 29(2022), No. 3, p. 563.

A.R.K. Gollakota, V. Volli, and C.M. Shu, Progressive utilisation prospects of coal fly ash: A review, Sci. Total Environ., 672(2019), p. 951.

S.K. Tripathy, J. Dasu, Y.R. Murthy, et al., Utilisation perspective on water quenched and air-cooled blast furnace slags, J. Clean. Prod., 262(2020), art. No. 121354.

World Steel Association, Global Crude Steel Output Decreases by 0.9% in 2020, World Steel Association, Brussels [2021-11-23]. https://worldsteel.org/media-centre/press-releases/2021/global-crude-steel-output-decreases-by-0-9-in-2020/

Q. Liu, W.Z. Liu, J.P. Hu, et al., Energy-efficient mineral carbonation of blast furnace slag with high value-added products, J. Clean. Prod., 197(2018), p. 242.

UN Environment, K.L. Scrivener, V.M. John, and E.M. Gartner, Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry, Cem. Concr. Res., 114(2018), p. 2.

S. Masoudi, S.M. Abtahi, and A. Goli, Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging, Constr. Build. Mater., 135(2017), p. 260.

H. Guo, S.H. Yin, Q.J. Yu, et al., Iron recovery and active residue production from basic oxygen furnace (BOF) slag for supplementary cementitious materials, Resour. Conserv. Recycl., 129(2018), p. 209.

S.Y. Zhuang and Q. Wang, Inhibition mechanisms of steel slag on the early-age hydration of cement, Cem. Concr. Res., 140(2021), art. No. 106283.

M.A. Khairul, J. Zanganeh, and B. Moghtaderi, The composition, recycling and utilisation of Bayer red mud, Resour. Conserv. Recycl., 141(2019), p. 483.

E. Mukiza, L.L. Zhang, and X.M. Liu, Durability and micro-structure analysis of the road base material prepared from red mud and flue gas desulfurization fly ash, Int. J. Miner. Metall. Mater., 27(2020), No. 4, p. 555.

J.Z. Zhang, Z.Y. Yao, K. Wang, et al., Sustainable utilization of bauxite residue (Red Mud) as a road material in pavements: A critical review, Constr. Build. Mater., 270(2021), art. No. 121419.

A. Bayat, A. Hassani, and A.A. Yousefi, Effects of red mud on the properties of fresh and hardened alkali-activated slag paste and mortar, Constr. Build. Mater., 167(2018), p. 775.

B.X. Peng, X.R. Li, W.H. Zhao, and L. Yang, Study on the release characteristics of chlorine in coal gangue under leaching conditions of different pH values, Fuel, 217(2018), p. 427.

X.Y. Zhang, C.Q. Li, S.L. Zheng, Y.H. Di, and Z.M. Sun, A review of the synthesis and application of zeolites from coal-based solid wastes, Int. J. Miner. Metall. Mater., 29(2022), No. 1, p. 1.

N. Zhang, H.X. Li, and X.M. Liu, Hydration mechanism and leaching behavior of bauxite-calcination-method red mud-coal gangue based cementitious materials, J. Hazard. Mater., 314(2016), p. 172.

B. Lothenbach, K. Scrivener, and R.D. Hooton, Supplementary cementitious materials, Cem. Concr. Res., 41(2011), No. 12, p. 1244.

B. Liu, S.G. Zhang, B.M. Steenari, and C. Ekberg, Synthesis and properties of SrFe12O19 obtained by solid waste recycling of oily cold rolling mill sludge, Int. J. Miner. Metall. Mater., 26(2019), No. 5, p. 642.

P. Suraneni and J. Weiss, Examining the pozzolanicity of supplementary cementitious materials using isothermal calorimetry and thermogravimetric analysis, Cem. Concr. Compos., 83(2017), p. 273.

M. Amran, G. Murali, N.H.A. Khalid, et al., Slag uses in making an ecofriendly and sustainable concrete: A review, Constr. Build. Mater., 272(2021), art. No. 121942.

S.Y. Pan, R. Adhikari, Y.H. Chen, P. Li, and P.C. Chiang, Integrated and innovative steel slag utilization for iron reclamation, green material production and CO2 fixation via accelerated carbonation, J. Clean. Prod., 137(2016), p. 617.

Y.B. Zong, C.Y. Zhao, W.H. Chen, Z.B. Liu, and D.Q. Cang, Preparation of hydro-sodalite from fly ash using a hydrothermal method with a submolten salt system and study of the phase transition process, Int. J. Miner. Metall. Mater., 27(2020), No. 1, p. 55.

J. de Brito and R. Kurda, The past and future of sustainable concrete: A critical review and new strategies on cement-based materials, J. Clean. Prod., 281(2021), art. No. 123558.

H. Hafez, D. Kassim, R. Kurda, R.V. Silva, and J. de Brito, Assessing the sustainability potential of alkali-activated concrete from electric arc furnace slag using the ECO2 framework, Constr. Build. Mater., 281(2021), art. No. 122559.

I. Lancellotti, F. Piccolo, K. Traven, et al., Alkali activation of metallurgical slags: Reactivity, chemical behavior, and environmental assessment, Materials (Basel), 14(2021), No. 3, art. No. 639.

Y.B. Wang, X.Y. He, Y. Su, et al., Efficiency of wet-grinding on the mechano-chemical activation of granulated blast furnace slag (GBFS), Constr. Build. Mater., 199(2019), p. 185.

S. Kumar, G. Mucsi, F. Kristály, and P. Pekker, Mechanical activation of fly ash and its influence on micro and nano-structural behaviour of resulting geopolymers, Adv. Powder Technol., 28(2017), No. 3, p. 805.

B. Wei, Y.M. Zhang, and S.X. Bao, Preparation of geopolymers from vanadium tailings by mechanical activation, Constr. Build. Mater., 145(2017), p. 236.

X.W. Gu, W.F. Zhang, X.L. Zhang, X.H. Li, and J.P. Qiu, Hydration characteristics investigation of iron tailings blended ultra high performance concrete: The effects of mechanical activation and iron tailings content, J. Build. Eng., 45(2022), art. No. 103459.

Y.B. Wang, X.Y. He, Y. Su, et al., Self-hydration characteristics of ground granulated blast-furnace slag (GGBFS) by wet-grinding treatment, Constr. Build. Mater., 167(2018), p. 96.

P. Baláž, M. Achimovičová, M. Baláž, et al., Hallmarks of mechanochemistry: From nanoparticles to technology, Chem. Soc. Rev., 42(2013), No. 18, p. 7571.

J.T. Ma, D.G. Wang, S.B. Zhao, P. Duan, and S.T. Yang, Influence of particle morphology of ground fly ash on the fluidity and strength of cement paste, Materials (Basel), 14(2021), No. 2, art. No. 283.

T. Wang, T. Ishida, and R. Gu, A comparison of the specific surface area of fly ash measured by image analysis with conventional methods, Constr. Build. Mater., 190(2018), p. 1163.

H.B. Tan, X.F. Deng, X.Y. He, et al., Compressive strength and hydration process of wet-grinded granulated blast-furnace slag activated by sodium sulfate and sodium carbonate, Cem. Concr. Compos., 97(2019), p. 387.

A. Bouaziz, R. Hamzaoui, S. Guessasma, et al., Efficiency of high energy over conventional milling of granulated blast furnace slag powder to improve mechanical performance of slag cement paste, Powder Technol., 308(2017), p. 37.

Y.L. Zhao, J.P. Qiu, Z.Y. Ma, and X.G. Sun, Eco-friendly treatment of coal gangue for its utilization as supplementary cementitious materials, J. Clean. Prod., 285(2021), art. No. 124834.

K. Kato, Y.Z. Xin, T. Hitomi, and T. Shirai, Surface modification of fly ash by mechano-chemical treatment, Ceram. Int., 45(2019), No. 1, p. 849.

S.Y. Duan, H.Q. Liao, Z.B. Ma, et al., The relevance of ultrafine fly ash properties and mechanical properties in its fly ash-cement gelation blocks via static pressure forming, Constr. Build. Mater., 186(2018), p. 1064.

M. Ozturk, M.B. Bankir, O.S. Bolukbasi, and U.K. Sevim, Alkali activation of electric arc furnace slag: Mechanical properties and micro analyzes, J. Build. Eng., 21(2019), p. 97.

Y.X. Guo, K.Z. Yan, L. Cui, and F.Q. Cheng, Improved extraction of alumina from coal gangue by surface mechanically grinding modification, Powder Technol., 302(2016), p. 33.

Y.C. Li, X.B. Min, Y. Ke, D.G. Liu, and C.J. Tang, Preparation of red mud-based geopolymer materials from MSWI fly ash and red mud by mechanical activation, Waste Manage., 83(2019), p. 202.

J.J. Geng, M. Zhou, Y.X. Li, et al., Comparison of red mud and coal gangue blended geopolymers synthesized through thermal activation and mechanical grinding preactivation, Constr. Build. Mater., 153(2017), p. 185.

P. Prziwara, S. Breitung-Faes, and A. Kwade, Comparative study of the grinding aid effects for dry fine grinding of different materials, Miner. Eng., 144(2019), art. No. 106030.

J.H. Zhao, D.M. Wang, X.G. Wang, S.C. Liao, and H. Lin, Ultrafine grinding of fly ash with grinding aids: Impact on particle characteristics of ultrafine fly ash and properties of blended cement containing ultrafine fly ash, Constr. Build. Mater., 78(2015), p. 250.

L. Krishnaraj and P.T. Ravichandran, Impact of chloride grinding aid with modified fly ash using topdown nanotechnology on grinding performance, Constr. Build. Mater., 199(2019), p. 225.

A.G. Wang, P. Liu, L.W. Mo, et al., Mechanism of thermal activation on granular coal gangue and its impact on the performance of cement mortars, J. Build. Eng., 45(2022), art. No. 103616.

Y.L. Zhang and T.C. Ling, Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials—A review, Constr. Build. Mater., 234(2020), art. No. 117424.

H.Q. Ma, H.Y. Chen, H.G. Zhu, et al., Study on the drying shrinkage of alkali-activated coal gangue-slag mortar and its mechanisms, Constr. Build. Mater., 225(2019), p. 204.

S. Yan, F.Y. Zhang, L. Wang, et al., A green and low-cost hollow gangue microsphere/geopolymer adsorbent for the effective removal of heavy metals from wastewaters, J. Environ. Manage., 246(2019), p. 174.

M.J. Moghadam, R. Ajalloeian, and A. Hajiannia, Preparation and application of alkali-activated materials based on waste glass and coal gangue: A review, Constr. Build. Mater., 221(2019), p. 84.

G.D. Huang, Y.S. Ji, J. Li, Z.H. Hou, and Z.C. Dong, Improving strength of calcinated coal gangue geopolymer mortars via increasing calcium content, Constr. Build. Mater., 166(2018), p. 760.

Y. Feng, Q.X. Yang, Q.S. Chen, et al., Characterization and evaluation of the pozzolanic activity of granulated copper slag modified with CaO, J. Clean. Prod., 232(2019), p. 1112.

N. Ye, Y. Chen, J.K. Yang, et al., Co-disposal of MSWI fly ash and Bayer red mud using an one-part geopolymeric system, J. Hazard. Mater., 318(2016), p. 70.

X.Y. Ke, S.A. Bernal, N. Ye, J.L. Provis, and J.K. Yang, One-part geopolymers based on thermally treated red mud/NaOH blends, J. Am. Ceram. Soc., 98(2015), No. 1, p. 5.

N. Ye, J.K. Yang, S. Liang, et al., Synthesis and strength optimization of one-part geopolymer based on red mud, Constr. Build. Mater., 111(2016), p. 317.

T. Luukkonen, Z. Abdollahnejad, J. Yliniemi, P. Kinnunen, and M. Illikainen, One-part alkali-activated materials: A review, Cem. Concr. Res., 103(2018), p. 21.

N. Koshy, K. Dondrob, L.M. Hu, Q.B. Wen, and J.N. Meegoda, Synthesis and characterization of geopolymers derived from coal gangue, fly ash and red mud, Constr. Build. Mater., 206(2019), p. 287.

W. Hu, Q.K. Nie, B.S. Huang, X. Shu, and Q. He, Mechanical and microstructural characterization of geopolymers derived from red mud and fly ashes, J. Clean. Prod., 186(2018), p. 799.

M. Nawaz, A. Heitor, and M. Sivakumar, Geopolymers in construction—Recent developments, Constr. Build. Mater., 260(2020), art. No. 120472.

S. Alahrache, F. Winnefeld, J.B. Champenois, F. Hesselbarth, and B. Lothenbach, Chemical activation of hybrid binders based on siliceous fly ash and Portland cement, Cem. Concr. Compos., 66(2016), p. 10.

Y.L. Zhao, J.P. Qiu, J. Xing, and X.G. Sun, Chemical activation of binary slag cement with low carbon footprint, J. Clean. Prod., 267(2020), art. No. 121455.

D.F. Velandia, C.J. Lynsdale, J.L. Provis, F. Ramirez, and A.C. Gomez, Evaluation of activated high volume fly ash systems using Na2SO4, lime and quicklime in mortars with high loss on ignition fly ashes, Constr. Build. Mater., 128(2016), p. 248.

D.E. Angulo-Ramírez, R. Mejía de Gutiérrez, and F. Puertas, Alkali-activated Portland blast-furnace slag cement: Mechanical properties and hydration, Constr. Build. Mater., 140(2017), p. 119.

S.K. Singh, Jyoti, and P. Vashistha, Development of newer composite cement through mechano-chemical activation of steel slag, Constr. Build. Mater., 268(2021), art. No. 121147.

A.M. Rashad, Y. Bai, P.A.M. Basheer, N.B. Milestone, and N.C. Collier, Hydration and properties of sodium sulfate activated slag, Cem. Concr. Compos., 37(2013), p. 20.

M. Liu, H.B. Tan, and X.Y. He, Effects of nano-SiO2 on early strength and microstructure of steam-cured high volume fly ash cement system, Constr. Build. Mater., 194(2019), p. 350.

D.B. Jiang, X.G. Li, Y. Lv, et al., Early-age hydration process and autogenous shrinkage evolution of high performance cement pastes, J. Build. Eng., 45(2022), art. No. 103436.

B. Lothenbach and F. Winnefeld, Thermodynamic modelling of the hydration of Portland cement, Cem. Concr. Res., 36(2006), No. 2, p. 209.

E. Berodier and K. Scrivener, Understanding the filler effect on the nucleation and growth of C—S—H, J. Am. Ceram. Soc., 97(2014), No. 12, p. 3764.

M. Cyr, P. Lawrence, and E. Ringot, Mineral admixtures in mortars: Quantification of the physical effects of inert materials on short-term hydration, Cem. Concr. Res., 35(2005), No. 4, p. 719.

Z.Q. Zhang, W.Y. Chen, F.H. Han, and P.Y. Yan, A new hydration kinetics model of composite cementitious materials, Part 2: Physical effect of SCMs, J. Am. Ceram. Soc., 103(2020), No. 6, p. 3880.

A. Xu, S.L. Sarkar, and L.O. Nilsson, Effect of fly ash on the microstructure of cement mortar, Mater. Struct., 26(1993), No. 7, p. 414.

B. Yin, T.H. Kang, J.T. Kang, et al., Investigation of the hydration kinetics and microstructure formation mechanism of fresh fly ash cemented filling materials based on hydration heat and volume resistivity characteristics, Appl. Clay Sci., 166(2018), p. 146.

C.J. Shi, A.F. Jiménez, and A. Palomo, New cements for the 21st century: The pursuit of an alternative to Portland cement, Cem. Concr. Res., 41(2011), No. 7, p. 750.

P.T. Durdziński, C.F. Dunant, M.B. Haha, and K.L. Scrivener, A new quantification method based on SEM—EDS to assess fly ash composition and study the reaction of its individual components in hydrating cement paste, Cem. Concr. Res., 73(2015), p. 111.

E. Tkaczewska, Effect of size fraction and glass structure of siliceous fly ashes on fly ash cement hydration, J. Ind. Eng. Chem., 20(2014), No. 1, p. 315.

C.Y. Wang, H.T. Peng, L.B. Bian, et al., Performance of alkali-activated cementitious composite mortar used for insulating walls, J. Build. Eng., 44(2021), art. No. 102867.

P. Duxson and J.L. Provis, Designing precursors for geopolymer cements, J. Am. Ceram. Soc., 91(2008), No. 12, p. 3864.

C. Li, H.H. Sun, and L.T. Li, A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements, Cem. Concr. Res., 40(2010), No. 9, p. 1341.

I. Garcia-Lodeiro, S. Donatello, A. Fernández-Jiménez, and Á. Palomo, Hydration of hybrid alkaline cement containing a very large proportion of fly ash: A descriptive model, Materials (Basel), 9(2016), No. 7, art. No. 605.

A. Palomo, P. Krivenko, I. Garcia-Lodeiro, et al., A review on alkaline activation: New analytical perspectives, Mater. Construcc., 64(2014), No. 315, art. No. e022.

I. García-Lodeiro, A. Fernández-Jiménez, and A. Palomo, Variation in hybrid cements over time. Alkaline activation of fly ash—Portland cement blends, Cem. Concr. Res., 52(2013), p. 112.

N. Cristelo, I. Garcia-Lodeiro, J.F. Rivera, et al., One-part hybrid cements from fly ash and electric arc furnace slag activated by sodium sulphate or sodium chloride, J. Build. Eng., 44(2021), art. No. 103298.

M. Wu, Y.S. Zhang, Y.S. Ji, et al., Reducing environmental impacts and carbon emissions: Study of effects of superfine cement particles on blended cement containing high volume mineral admixtures, J. Clean. Prod., 196(2018), p. 358.

L. Nguyen, A.J. Moseson, Y. Farnam, and S. Spatari, Effects of composition and transportation logistics on environmental, energy and cost metrics for the production of alternative cementitious binders, J. Clean. Prod., 185(2018), p. 628.

M.U. Hossain, J.C. Liu, D.X. Xuan, et al., Designing sustainable concrete mixes with potentially alternative binder systems: Multicriteria decision making process, J. Build. Eng., 45(2022), art. No. 103587.

M.K.H. Radwan, C.C. Onn, K.H. Mo, et al., Eco-mechanical performance of binary and ternary cement blends containing fly ash and slag, Proc. Inst. Civ. Eng. Eng. Sustain., 174(2021), No. 1, p. 23..

C. Kulasuriya, V. Vimonsatit, and W.P.S. Dias, Performance based energy, ecological and financial costs of a sustainable alternative cement, J. Clean. Prod., 287(2021), art. No. 125035.

S. Espuelas, A.M. Echeverria, S. Marcelino, E. Prieto, and A. Seco, Technical and environmental characterization of hydraulic and alkaline binders, J. Clean. Prod., 196(2018), p. 1306.

Acknowledgements

This work was financially supported by the National Key R&D Program of China (Nos. 2019YFC1907101 and 2021YFC1910504), Key R&D Program of Ningxia Hui Autonomous Region (Nos. 2020BCE01001 and 2021BEG 01003), National Natural Science Foundation of China (Nos. U2002212 and 51672024), Xijiang Innovation and Entrepreneurship Team (No. 2017A0109004), the Fundamental Research Funds for the Central Universities (Nos. FRF-BD-20-24A, FRF-TP-20-031A1, FRF-IC-19-017Z, FRF-GF-19-032B, and 06500141), and Integration of Green Key Process Systems MIIT.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Zhang, Q., Liu, B., Xiao, K. et al. Preparation and hydration of industrial solid waste—cement blends: A review. Int J Miner Metall Mater 29, 2106–2116 (2022). https://doi.org/10.1007/s12613-022-2538-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2538-9