Abstract

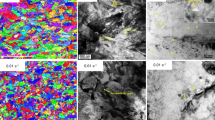

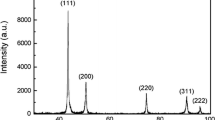

The hot deformation behaviors of a 9Cr oxide dispersion-strengthened (9Cr-ODS) steel fabricated by mechanical alloying and hot isostatic pressing (HIP) were investigated. Hot compression deformation experiments were conducted on a Gleeble 3500 simulator in a temperature range of 950–1100°C and strain rate range of 0.001–1 s−1. The constitutive equation that can accurately describe the relationship between the rheological stress and the strain rate of the 9Cr-ODS steel was established, and the deformation activation energy was calculated as 780.817 kJ/mol according to the data obtained. The processing maps of 9Cr-ODS in the strain range of 0.1–0.6 were also developed. The results show that the region with high power dissipation efficiency corresponds to a completely recrystallized structure. The optimal processing conditions were determined as a temperature range of 1000–1050°C with strain rate between 0.003 and 0.01 s−1.

Similar content being viewed by others

References

S. Chu and A. Majumdar, Opportunities and challenges for a sustainable energy future, Nature, 488(2012), No. 7411, p. 294.

H.Q. Dong, L.M. Yu, Y.C. Liu, C.X. Liu, H.J. Li, and J.F. Wu, Effect of hafnium addition on the microstructure and tensile properties of aluminum added high-Cr ODS steels, J. Alloys Compd., 702(2017), p. 538.

H. Xu, Z. Lu, D. Wang, and C. Liu, Microstructure refinement and strengthening mechanisms of a 9Cr oxide dispersion strengthened steel by zirconium addition, Nucl. Eng. Technol., 49(2017), No. 1, p. 178.

G.M. Zhang, Z.J. Zhou, K. Mo, P.H. Wang, Y.B. Miao, S.F. Li, M. Wang, X. Liu, M.Q. Gong, J. Almer, and J.F. Stubbins, The microstructure and mechanical properties of Al-containing 9Cr ODS ferritic alloy, J. Alloys Compd., 648(2015), p. 223.

Q. Zhao, L.M. Yu, Y.C. Liu, Y. Huang, Z.Q. Ma, and H.J. Li, Effects of aluminum and titanium on the microstructure of ODS steels fabricated by hot pressing, Int. J. Miner. Metall. Mater., 25(2018), No. 10, p. 1156.

S. Ukai, M. Harada, H. Okada, M. Inoue, S. Nomura, S. Shikakura, K. Asabe, T. Nishida, and M. Fujiwara, Alloying design of oxide dispersion strengthened ferritic steel for long life FBRs core materials, J. Nucl. Mater., 204(1993), p. 65.

C. Suryanarayana and N. Al-Aqeeli, Mechanically alloyed nanocomposites, Prog. Mater. Sci., 58(2013), No. 4, p. 383.

S. Ukai and M. Fujiwara, Perspective of ODS alloys application in nuclear environments, J. Nucl. Mater., 307–311(2002), p. 749.

G.R. Odette, M.J. Alinger, and B.D. Wirth, Recent developments in irradiation-resistant steels, Ann. Rev. Mater. Res., 38(2008), p. 471.

E.J. Mittemeijer, Fundamentals of Materials Science, Springer Berlin, Heidelberg, 2011, p. 101.

Y. Sugino, S. Ukai, N. Oono, S. Hayashi, T. Kaito, S. Ohtsuka, H. Masuda, S. Taniguchi, and E. Sato, High temperature deformation mechanism of 15CrODS ferritic steels at cold-rolled and recrystallized conditions, J. Nucl. Mater., 466(2015), p. 653.

E. Aydogan, O. El-Atwani, S. Takajo, S.C. Vogel, and S.A. Maloy, High temperature microstructural stability and recrystallization mechanisms in 14YWT alloys, Acta Mater., 148(2018), p. 467.

Y. Sugino, S. Ukai, B. Leng, N. Oono, S. Hayashi, T. Kaito, and S. Ohtsuka, Grain boundary sliding at high temperature deformation in cold-rolled ODS ferritic steels, J. Nucl. Mater., 452(2014), No. 1–3, p. 628.

Z.B. Zhang and W.G. Pantheon, Response of oxide nanoparticles in an oxide dispersion strengthened steel to dynamic plastic deformation, Acta Mater., 149(2018), p. 235.

Y.C. Lin and X.M. Chen, A critical review of experimental results and constitutive descriptions for metals and alloys in hot working, Mater. Des., 32(2011), No. 4, p. 1733.

S.B. Davenport, N.J. Silk, C.N. Sparks, and C.M. Sellars, Development of constitutive equations for modelling of hot rolling, Mater. Sci. Technol., 16(2000), No. 5, p. 539.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242, Metall. Trans. A, 15(1984), No. 10, p. 1883.

H. Zhang, H.J. Li, Q.Y. Guo, Y.C. Liu, and L.M. Yu, Hot deformation behavior of Ti—22Al—25Nb alloy by processing maps and kinetic analysis, J. Mater. Res., 31(2016), No. 12, p. 1764.

Z.H. Yao, S.C. Wu, J.X. Dong, Q.Y. Yu, M.C. Zhang, and G.W. Han, Constitutive behavior and processing maps of low-expansion GH909 superalloy, Int. J. Miner. Metall. Mater., 24(2017), No. 4, p. 432.

S. Huang, L. Wang, X.T. Lian, G.P. Zhao, F.F. Li, and X.M. Zhang, Hot deformation map and its application of GH4706 alloy, Int. J. Miner. Metall. Mater., 21(2014), No. 5, p. 462.

J.Q. Zhang, H.S. Di, K. Mao, X.Y. Wang, Z.J. Han, and T.J. Ma, Processing maps for hot deformation of a high-Mn TWIP steel: A comparative study of various criteria based on dynamic materials model, Mater. Sci. Eng. A, 587(2013), p. 110.

Y.T. Wu, Y.C. Liu, C. Li, X.C. Xia, Y. Huang, H.J. Li, and H.P. Wang, Deformation behavior and processing maps of Ni3Al-based superalloy during isothermal hot compression, J. Alloys Compd., 712(2017), p. 687.

Z.Y. Ding, Q.D. Hu, L. Zeng, and J.G. Li, Hot deformation characteristics of as-cast high-Cr ultra-super-critical rotor steel with columnar grains, Int. J. Miner. Metall. Mater., 23(2016), No. 11, p. 1275.

R.H. Zhang, Z.A. Zhou, M.W. Guo, J.J. Qi, S.H. Sun, and W.T. Fu, Hot deformation mechanism and microstructure evolution of an ultra-high nitrogen austenitic steel containing Nb and V, Int. J. Miner. Metall. Mater., 22(2015), No. 10, p. 1043.

X.H. Yue, C.F. Liu, H.H. Liu, S.F. Xiao, Z.H. Tang, and T. Tang, Effects of hot compression deformation temperature on the microstructure and properties of Al—Zr—La alloys, Int. J. Miner. Metall. Mater., 25(2018), No. 2, p. 236.

M. Yamamoto, S. Ukai, S. Hayashi, T. Kaito, and S. Ohtsuka, Formation of residual ferrite in 9Cr-ODS ferritic steels, Mater. Sci. Eng. A, 527(2010), No. 16–17, p. 4418.

H. Sakasegawa, M. Tamura, S. Ohtsuka, S. Ukai, H. Tanigawa, A. Kohyama, and M. Fujiwara, Precipitation behavior of oxide particles in mechanically alloyed powder of oxide-dispersion-strengthened steel, J. Alloys Compd., 452(2008), No. 1, p. 2.

K.T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, and C.S. Lee, Stacking fault energy and plastic deformation of fully austenitic high manganese steels, Mater. Sci. Eng. A, 527(2010), No. 16–17, p. 3651.

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, and M. He, Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation, Mater. Des., 57(2014), p. 568.

A. Seeger, J. Diehl, S. Mader, and H. Rebstock, Work-hardening and work-softening of face-centred cubic metal crystals, Philos. Mag. A, 2(1957), No. 15, p. 323.

J.J. Jonas, C.M. Sellars, and W.J.M. Tegart, Strength and structure under hot-working conditions, Metall. Rev., 14(1969), No. 1, p. 1.

M.F. Abbod, C.M. Sellars, A. Tanaka. D.A. Linkens, and M. Mahfouf, Effect of changing strain rate on flow stress during hot deformation of Type 316L stainless steel, Mater. Sci. Eng. A, 491(2008), No. 1–2, p. 290.

C. Capdevila, G. Pimentel, M.M. Aranda, R. Rementeria, K. Dawson, E. Urones-Garrote, G.J. Tatlock, and M.K. Miller, Role of Y-Al oxides during extended recovery process of a ferritic ODS alloy, JOM, 67(2015), No. 10, p. 2208.

W.F. Zhang, W. Sha, W. Yan, W. Wang, Y.Y. Shan, and K. Yang, Analysis of deformation behavior and workability of advanced 9Cr—Nb—V ferritic heat resistant steels, Mater. Sci. Eng. A, 604(2014), p. 207.

H.T. Zhao, G.Q. Liu, and L. Xu, Rate-controlling mechanisms of hot deformation in a medium carbon vanadium microalloy steel, Mater. Sci. Eng. A, 559(2013), p. 262.

S.F. Medina and C.A. Hernandez, General expression of the Zener-Hollomon parameter as a function of the chemical composition of low alloy and microalloyed steels, Acta Mater., 44(1996), No. 1, p. 137.

J. Dong, C. Li, C.X. Liu, Y. Huang, L.M. Yu, H.J. Li, and Y.C. Liu, Hot deformation behavior and microstructural evolution of Nb—V—Ti microalloyed ultra-high strength steel, J. Mater. Res., 32(2017), No. 19, p. 3777.

C. Zener and J.H. Hollomon, Effect of strain rate upon plastic flow of steel, J. Appl. Phys., 15(1944), No. 1, p. 22.

R. Raj, Development of a processing map for use in warm-forming and hot-forming processes, Metall. Trans. A, 12(1981), No. 6, p. 1089.

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of hot deformation for microstructural control, Int. Mater. Rev., 43(1998), No. 6, p. 243.

P.Y. Zhao, Y.Z. Wang, and S.R. Niezgoda, Microstructural and micromechanical evolution during dynamic recrystallization, Int. J. Plast., 100(2017), p. 52.

H. Wu, S.P. Wen, H. Huang, X.L. Wu, K.Y. Gao, W. Wang, and Z.R. Nie, Hot deformation behavior and constitutive equation of a new type Al—Zn—Mg—Er—Zr alloy during isothermal compression, Mater. Sci. Eng. A, 651(2016), p. 415.

D.X. Wen, Y.C. Lin, H.B. Li, X.M. Chen, J. Deng, and L.T. Li, Hot deformation behavior and processing map of a typical Ni-based superalloy, Mater. Sci. Eng. A, 591(2014), p. 183.

H. Farnoush, A. Momeni, K. Dehghani, J. Aghazadeh Mohandesi, and H. Keshmiri, Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases, Mater. Des., 31(2010), No. 1, p. 220.

S.L. Sun, M.G. Zhang, and W.W. He, Hot deformation behavior and hot processing map of P92 steel, Adv. Mater. Res., 97–101(2010), p. 290.

A. Galiyev, R. Kaibyshev, and G. Gottstein, Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60, Acta Mater., 49(2001), No. 7, p. 1199.

S.S.S. Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, and U. Borah, Strain rate dependent microstructural evolution during hot deformation of a hot isostatically processed nickel base superalloy, J. Alloys Compd., 681(2016), p. 28.

Acknowledgements

This work was financially supported by the International Thermonuclear Experimental Reactor Program Special Project (Nos. 2015GB107003 and 2015GB119001), and the National Natural Science Foundation of China (Nos. 11672200, 51674175, and U1660201), and the Science and Technology Program of Tianjin, China (No. 18YFZCGX00070).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shao, Y., Yu, Lm., Liu, Yc. et al. Hot deformation behaviors of a 9Cr oxide dispersion-strengthened steel and its microstructure characterization. Int J Miner Metall Mater 26, 597–610 (2019). https://doi.org/10.1007/s12613-019-1768-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1768-y