Abstract

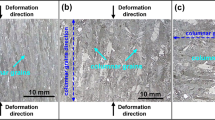

Isothermal hot compression tests of as-cast high-Cr ultra-super-critical (USC) rotor steel with columnar grains perpendicular to the compression direction were carried out in the temperature range from 950 to 1250°C at strain rates ranging from 0.001 to 1 s−1. The softening mechanism was dynamic recovery (DRV) at 950°C and the strain rate of 1 s−1, whereas it was dynamic recrystallization (DRX) under the other conditions. A modified constitutive equation based on the Arrhenius model with strain compensation reasonably predicted the flow stress under various deformation conditions, and the activation energy was calculated to be 643.92 kJ∙mol−1. The critical stresses of dynamic recrystallization under different conditions were determined from the work-hardening rate (θ)–flow stress (σ) and −∂θ/∂σ–σ curves. The optimum processing parameters via analysis of the processing map and the softening mechanism were determined to be a deformation temperature range from 1100 to 1200°C and a strain-rate range from 0.001 to 0.08 s−1, with a power dissipation efficiency η greater than 31%.

Similar content being viewed by others

References

M.I. Isik, A. Kostka, V.A. Yardley, K.G. Pradeep, M.J. Duarte, P.P. Choi, D. Raabe and G. Eggeler, The nucleation of Mo-rich Laves phase particles adjacent to M23C6 micrograin boundary carbides in 12% Cr tempered martensite ferritic steels, Acta Mater., 90(2015), p. 94.

G. Götz and W. Blum, Influence of thermal history on precipitation of hardening phases in tempered martensite 10%Cr-steel X12CrMoWVNbN 10-1-1, Mater. Sci. Eng. A, 348(2003), No. 1-2, p. 201.

F. Chen, Z.S. Cui, D.S. Sui, and B. Fu, Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation: Part III. Metadynamic recrystallization, Mater. Sci. Eng. A, 540(2012), p. 46.

F. Chen, Z.S. Cui, and S.J. Chen, Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation: Part I. Dynamic recrystallization, Mater. Sci. Eng. A, 528(2011), No. 15, p. 5073.

J. Hald, Microstructure and long-term creep properties of 9-12% Cr steels, Int. J. Pressure Vessels Piping, 85(2008), No. 1-2, p. 30.

R.L. Klueh and A.T. Nelson, Ferritic/martensitic steels for next-generation reactors, J. Nucl. Mater., 371(2007), No. 1-3, p. 37.

M.C. Flemings, Solidification processing, Metall. Trans., 5(1974), p. 2121.

G.W. Liu, Y. Han, Z.Q. Shi, J.P. Sun, D.N. Zou, and G.J. Qiao, Hot deformation and optimization of process parameters of an as-cast 6Mo superaustenitic stainless steel: a study with processing map, Mater. Des., 53(2014), p. 662.

E.X. Pu, W.J. Zheng, J.Z. Xiang, Z.G. Song, and J. Li, Hot deformation characteristic and processing map of superaustenitic stainless steel S32654, Mater. Sci. Eng. A, 598(2014), p. 174.

T. Xi, C.G. Yang, M. Babar Shahzad, and K. Yang, Study of the processing map and hot deformation behavior of a Cu-bearing 317LN austenitic stainless steel, Mater. Des., 87(2015), p. 303.

H. Mirzadeh and A. Najafizadeh, Hot deformation and dynamic recrystallization of 17-4 PH stainless steel, ISIJ Int., 53(2013), No. 4, p. 680.

B.Z. Wang, W.T. Fu, Z.Q. Lv, P. Jiang, W.H. Zhang, and Y.J. Tian, Study on the hot deformation behavior of 12%Cr ultra- super-critical rotor steel, Mater. Sci. Eng. A, 487(2008), No. 1-2, p. 108.

Z.H. Wang, W.T. Fu, B.Z. Wang, W.H. Zhang, Z.Q. Lv, and P. Jiang, Study on hot deformation characteristics of 12%Cr ultra-super-critical rotor steel using processing maps and Zener-Hollomon parameter, Mater. Charact., 61(2010), No. 1, p. 25.

L. Zeng, M.Q. Xu, X.R. Ma, Y.J. Huang, S.G. Zhang, Q.D. Hu, and J.G. Li, Grain refinement and delta ferrite reduction of high Cr steel ingots by thermal control, ISIJ Int., 54(2014), No. 10, p. 2302.

C. Zhang, L.W. Zhang, W.F. Shen, C.R. Liu, Y.N. Xia, and R.Q. Li, Study on constitutive modeling and processing maps for hot deformation of medium carbon Cr-Ni-Mo alloyed steel, Mater. Des., 90(2016), p. 804.

Z.Y. Ding, S.G. Jia, P.F. Zhao, M. Deng, and K.X. Song, Hot deformation behavior of Cu-0.6Cr-0.03Zr alloy during compression at elevated temperatures, Mater. Sci. Eng. A, 570(2013), p. 87.

Y. Han, D.N. Zou, Z.Y. Chen, G.W. Fan, and W. Zhang, Investigation on hot deformation behavior of 00Cr23Ni4N duplex stainless steel under medium-high strain rates, Mater. Charact., 62(2011), No. 2, p. 198.

D. Ponge and G. Gottstein, Necklace formation during dynamic recrystallization: mechanisms and impact on flow behavior, Acta Mater., 46(1998), No. 1, p. 69.

J. Luo, L.F. Wang, S.F. Liu, and M.Q. Li, The correlation between the flow behavior and the microstructure evolution during hot working of TC18 alloy, Mater. Sci. Eng. A, 654(2016), p. 213.

H. Farnoush, A. Momeni, K. Dehghani, J. Aghazadeh Mohandesi, and H. Keshmiri, Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases, Mater. Des., 31(2010), No. 1, p. 220.

G.R. Ebrahimi, H. Keshmiri, A.R. Maldar, and A. Momeni, Dynamic recrystallization behavior of 13%Cr martensitic stainless steel under hot working condition, J. Mater. Sci. Technol., 28(2012), No. 5, p. 467.

C.M. Sellars and W.J. McG. Tegart, Hot workability, Int. Metall. Rev., 17(1972), No. 1, p. 1.

J. Wang, G.Q. Zhao, L. Chen, and J.L. Li, A comparative study of several constitutive models for powder metallurgy tungsten at elevated temperature, Mater. Des., 90(2016), p. 91.

E.I. Poliak and J.J. Jonas, A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization, Acta Mater., 44(1996), No. 1, p. 127.

N.D. Ryan and H.J. McQueen, Dynamic softening mechanisms in 304 austenitic stainless steel, Can. Metall. Q, 29(1990), No. 2, p. 147.

D.Q. Dong, F. Chen, and Z.S. Cui, A physically-based constitutive model for SA508 steel: modeling and experimental verification, Mater. Sci. Eng. A, 634(2015), p. 103.

Y. Han, H. Wu, W. Zhang, D.N. Zou, G.W. Liu, and G.J. Qiao, Constitutive equation and dynamic recrystallization behavior of as-cast 254SMO super-austenitic stainless steel, Mater. Des., 69(2015), p. 230.

Y.V.R.K. Prasad, K.P. Rao, and S. Sasidhara, Hot Working Guide: a Compendium of Processing Maps, ASM, Ohio, 1997.

M. Sarebanzadeh, R. Mahmudi, and R. Roumina, Constitutive analysis and processing map of an extruded Mg-3Gd-1Zn alloy under hot shear deformation, Mater. Sci. Eng. A, 637(2015), p. 155.

Y.S. Wu, M.C. Zhang, X.S. Xie, J.X. Dong, F.S. Lin, and S.Q. Zhao, Hot deformation characteristics and processing map analysis of a new designed nickel-based alloy for 700°C A-USC power plant, J. Alloys Compd., 656(2016), p. 119.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, Zy., Hu, Qd., Zeng, L. et al. Hot deformation characteristics of as-cast high-Cr ultra-super-critical rotor steel with columnar grains. Int J Miner Metall Mater 23, 1275–1285 (2016). https://doi.org/10.1007/s12613-016-1349-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1349-2