Abstract

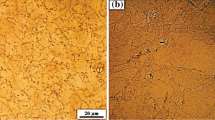

The hot deformation behavior of uniform fine-grained GH4720Li alloy was studied in the temperature range from 1040 to 1130°C and the strain-rate range from 0.005 to 0.5 s−1 using hot compression testing. Processing maps were constructed on the basis of compression data and a dynamic materials model. Considerable flow softening associated with superplasticity was observed at strain rates of 0.01 s−1 or lower. According to the processing map and observations of the microstructure, the uniform fine-grained microstructure remains intact at 1100°C or lower because of easily activated dynamic recrystallization (DRX), whereas obvious grain growth is observed at 1130°C. Metallurgical instabilities in the form of non-uniform microstructures under higher and lower Zener–Hollomon parameters are induced by local plastic flow and primary γ′ local faster dissolution, respectively. The optimum processing conditions at all of the investigated strains are proposed as 1090–1130°C with 0.08–0.5 s−1 and 0.005–0.008 s−1 and 1040–1085°C with 0.005–0.06 s−1.

Similar content being viewed by others

References

J.R. Vaunois, J. Cormier, P. Villechaise, A. Devaux, and B. Flageolet, Influence of both γ' distribution and grain size on the tensile properties of Udimet 720Li at room temperature, [in] Superalloys 718 and Derivatives, Pittsburgh, 2010, p. 199.

M.P. Jackson and R.C. Reed, Heat treatment of Udimet 720Li: the effect of microstructure on properties, Mater. Sci. Eng. A, 259(1999), No. 1, p. 85.

D.J. Bryant and D.G. McIntosh, The manufacture and evaluation of a large turbine disc in cast and wrought alloy 720Li, [in] Superalloys 1996, Proceeding of the 8th International Symposium on Superalloys, Champion, PA, 1996, p. 713.

Y.S. Na, N.K. Park, and R.C. Reed, Sigma morphology and precipitation mechanism in Udimet 720Li, Scripta Mater., 43(2000), No. 7, p. 585.

S.E. Kim, M.P. Jackson, R.C. Reed, C. Small, A. James, and N.K. Park, Quantification of the minor precipitates in Udimet alloy720(Li) using electrolytic extraction and X-ray diffraction, Mater. Sci. Eng. A, 245(1998), No. 2, p. 225.

J.M. Hyzak, R.P. Singh, and J.E. Morra, The microstructural response of as-hip P/M U720 to thermomechanical processing, [in] Superalloys 1992, Proceeding of the 7th International Symposium on Superalloys, Champion, PA, 1992, p. 93.

B. Lindsley and X. Pierron, Sub-solvus recrystallization mechanisms in UDIMET alloy 720LI, [in] Superalloys 2000, Proceeding of the 9th International Symposium on Superalloys, Champion, PA, 2000,. 59.

Y.X. Zhao, S.H. Fu, S.W. Zhang, X. Tang, N. Liu, and G.Q. Zhang, An advanced cast/wrought technology for GH720Li alloy disk from fine grain ingot, [in] Superalloys 718 and Derivatives, Pittsburgh, 2010, p. 271.

J.L. Qu, Z.N. Bi, J.H. Du, M.Q. Wang, Q.Z. Wang, and J. Zhang, Hot deformation behavior of nickel-based superalloy GH4720, J. Iron Steel Res. Int., 18(2011), No. 10, p. 59.

T. Matsui, H. Takizawa, H. Kikuchi, and S. Wakita, The microstructure prediction of alloy720Li for turbine disk application, [in] Superalloys 2000, Proceeding of the 9th International Symposium on superalloys, Champion, PA, 2000, p. 127.

H. Monajati, A.K. Taheri, M. Jahazi, and S. Yue, Deformation characteristics of isothermally forged Udimet720 nickel-base superalloy, Metall. Mater. Trans. A, 36(2005), No. 4, p. 895.

K.A. Green, J.A. Lemsky, and R.M. Gasior, Development of isothermally forged P/M Udimet 720Li for turbine disk application, [in] Superalloys 1996, Proceeding of the 8th International Symposium on Superalloys, Champion, PA, 1996, p. 697.

D.Y. Cai, L.Y. Xiong, W.C. Liu, G.D. Sun, and M. Yao, Development of processing maps for a Ni-based superalloy, Mater. Charact., 58(2007), No. 10, p. 941.

M.C. Somani, K. Muraleedharan, Y. V.R.K. Prasad, and V. Singh, Mechanical processing and microstructural control in hot working of hot isostatically pressed P/M IN-100 superalloy, Mater. Sci. Eng. A, 245(1998), No. 1, p. 88.

Y.Q. Ning, Z.K. Yao, H.Z. Guo, M.W. Fu, H. Li, and X.H. Xie, Investigation on hot deformation behavior of P/M Ni-base superalloy FGH96 by using processing maps, Mater. Sci. Eng. A, 527(2010), No. 26, p. 6794.

Q.L. Pan, B. Li, Y. Wang, Y.W. Zhang, and Z.M. Yin, Characterization of hot deformation behavior of Ni-base superalloy Rene'41 using processing map, Mater. Sci. Eng. A, 585(2013), p. 371.

M.A. Khafri and N. Golarzi, Forming behavior and workability of Hastelloy X superalloy during hot deformation, Mater. Sci. Eng. A, 486(2008), No. 1-2, p. 641.

S. Huang, L. Wang, X.T. Lian, G.P. Zhao, F.F. Li, and X.M. Zhang, Hot deformation map and its application of GH4706 alloy, Int. J. Miner. Metall. Mater., 21(2014), No. 5, p. 462.

M.J. Zhang, F.G. Li, S.Y. Wang, and C.Y. Liu, Characterization of hot deformation behavior of a P/M nickel-base superalloy using processing map and activation energy, Mater. Sci. Eng. A, 527(2010), No. 24-25, p. 6771.

K. Wu, G.Q. Liu, B.F. Hu, F. Li, Y.W. Zhang, Y. Tao, and J.T. Liu, Characterization of hot deformation behavior of a new Ni-Cr-Co based P/M superalloy, Mater. Charact., 61(2010), No. 3, p. 330.

Y.Q. Ning, Z.K. Yao, Y.Y. Lei, H.Z. Guo, and M.W. Fu, Hot deformation behavior of the post-cogging FGH4096 superalloy with fine equiaxed microstructure, Mater. Charact., 62(2011), No. 9, p. 887.

M. Haj, H. Mansouri, R. Vafaei, G.R. Ebrahimi, and A. Kanani, Hot compression deformation behavior of AISI 321 austenitic stainless steel, Int. J. Miner. Metall. Mater., 20(2013), No. 6, p. 529.

Y.V.R.K. Prasad, Processing maps: a status report, J. Mater. Eng. Perform., 12(2003), No. 6, p. 638.

S.V.S. Narayana Murty, B. Nageswarra Rao, and B.P. Kashyap, Instability criteria for hot deformation of materials, Int. Mater. Rev., 45(2000), No. 1, p. 15.

R. Raj, Development of a processing map for use in warm-forming and hot-forming processes, Metall. Trans. A, 12(1981), No. 6, p. 1089.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Qy., Yao, Zh. & Dong, Jx. Hot deformation behavior of uniform fine-grained GH4720Li alloy based on its processing map. Int J Miner Metall Mater 23, 83–91 (2016). https://doi.org/10.1007/s12613-016-1214-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1214-3