Abstract

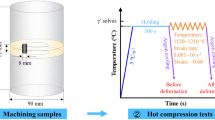

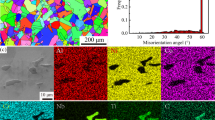

The hot deformation behaviour of the GH4169 alloy in two different initial states (homogeneous and mixed-crystal states) was investigated by performing isothermal compression tests at different strain rates (0.01-1 s−1) and deformation temperatures (1050-1150 °C). Hot-working diagrams were established for both alloy types, and the microstructural evolution in both alloy types during hot deformation was analysed to determine the corresponding deformation mechanism. The experimental results showed that the peak stress of the homogeneous alloy was lower than that of the mixed-crystal alloy for the same temperature and strain rate. Based on the processing maps, the flow instability domain of the homogeneous alloy exceeded that of the mixed-crystal alloy. The optimal processing parameters of the homogeneous alloy were 0.01-0.1 s−1/1050-1100 °C, and 0.01-0.1 s−1/1050-1080 °C (at a lower strain state) or 1100-1150 °C (at a higher strain state) was optimal for the mixed-crystal alloy. Microstructural analysis revealed that the differences in the hot deformation behaviour of the homogeneous and mixed-crystal alloys were caused by the different initial grain sizes and dynamic recrystallization (DRX) mechanisms. The main DRX nucleation method of the homogeneous alloy was discontinuous DRX, whereas that of the mixed-crystal alloy was continuous DRX and discontinuous DRX.

Similar content being viewed by others

References

J. Xu, X.K. Sun, Q.Q. Liu, and W.X. Chen, Hydrogen Permeation Behavior in IN718 and GH761 Superalloys, Metallurgical and Materials Transactions, Phys. Metall. Mater. Sci., 1994, 25, p 539–544. https://doi.org/10.1007/BF02651595

K.V.U. Praveen, G.V.S. Sastry, and V. Singh, Work-Hardening Behavior of the Ni-Fe Based Superalloy IN718, Metallurgical and Materials Transactions, Phys. Metall. Mater. Sci., 2008, 39, p 65–78. https://doi.org/10.1007/s11661-007-9375-3

Y. Mei, Y. Liu, C. Liu, C. Li, L. Yu, Q. Guo, and H. Li, Effects of Cold Rolling on the Precipitation Kinetics and the Morphology Evolution of Intermediate Phases in Inconel 718 Alloy, J. Alloys Compounds, 2015, 649, p 949–960. https://doi.org/10.1016/j.jallcom.2015.07.149

K.D. Ramkumar, S. Dev, V. Saxena, A. Choudhary, N. Arivazhagan, and S. Narayanan, Effect of Flux Addition on the Microstructure and Tensile Strength of Dissimilar Weldments Involving Inconel 718 and AISI 416, Mater. Design, 2015, 87, p 663–674. https://doi.org/10.1016/j.matdes.2015.08.075

X. Yang, W. Li, J. Li, T. Ma, and J. Guo, FEM Analysis of Temperature Distribution and Experimental Study of Microstructure Evolution in Friction Interface of GH4169 Superalloy, Mater. Design, 2015, 84, p 133–143. https://doi.org/10.1016/j.matdes.2015.06.123

Q. Jia and D. Gu, Selective Laser Melting Additive Manufacturing of Inconel 718 Superalloy Parts: Densification, Microstructure and Properties, J. Alloys Compounds, 2014, 585, p 713–721. https://doi.org/10.1016/j.jallcom.2013.09.171

G.F. Lovicu, C. Colombo, M. De Sanctis, and R. Valentini, Hydrogen Uptake Enhancement and Accelerated Hydrogen Re-Embrittlement of Cd-Plated AISI 4340 Steel Bolts Coupled with IN718 Nuts, Metall. Mater. Trans. A, 2011, 42(12), p 3577–3580. https://doi.org/10.1007/s11661-011-0880-z

F. Klocke, V. Bäcker, H. Wegner, B. Feldhaus, H.U. Baron, and R. Hessert, Influence of Process and Geometry Parameters on the Surface Layer State After Roller Burnishing of IN718, Prod. Eng., 2009, 3(4), p 391–399. https://doi.org/10.1007/s11740-009-0182-0

Y.B. Tan, Y.H. Ma, and F. Zhao, Hot Deformation Behavior and Constitutive Modeling of Fine Grained Inconel 718 Superalloy, J. Alloys Compounds, 2018, 741, p 85–96. https://doi.org/10.1016/j.jallcom.2017.12.265

Z. Wan, Hu. Lianxi, Yu. Sun, T. Wang, and Z. Li, Hot Deformation Behavior and Processing Workability of a Ni-Based Alloy, J. Alloy. Compd., 2018, 769, p 367–375. https://doi.org/10.1016/j.jallcom.2018.08.010

A. Nicolaÿ, G. Fiorucci, J.M. Franchet, J. Cormier, and N. Bozzolo, Influence of Strain Rate on Subsolvus Dynamic and Post-dynamic Recrystallization Kinetics of Inconel 718, Acta Mater., 2019, 174, p 406–417. https://doi.org/10.1016/j.actamat.2019.05.061

D. Jia, W. Sun, Xu. Dongsheng, Yu. Lianxu, X. Xin, W. Zhang, and F. Qi, Abnormal Dynamic Recrystallization Behavior of a Nickel Based Superalloy During hot Deformation, J. Alloy. Compd., 2019, 787, p 196–205. https://doi.org/10.1016/j.jallcom.2019.02.055

S.N. Murty and B.N. Rao, On the Flow Localization Concepts in the Processing Maps of Titanium Alloy Ti–24Al–20Nb, J. Mater. Process. Technol., 2000, 104(1–2), p 103–109. https://doi.org/10.1016/S0924-0136(00)00517-3

Y.V.R.K. Prasad, T. Seshacharyulu, S.C. Medeiros, and W.G. Frazier, Influence of Oxygen Content on the Forging Response of Equiaxed (α+ β) Preform of Ti–6Al–4V: Commercial vs. ELI Grade, J. Mater. Process. Technol., 2001, 108(3), p 320–327. https://doi.org/10.1016/S0924-0136(00)00832-3

S.S. Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, and U. Borah, Work Hardening Characteristics and Microstructural Evolution During Hot Deformation of a Nickel Superalloy at Moderate Strain Rates, J. Alloys Compounds, 2017, 709, p 394–409. https://doi.org/10.1016/j.jallcom.2017.03.158

S.S. Satheesh Kumar, T. Raghu, P.P. Bhattacharjee, G. Appa Rao, and U. Borah, Constitutive Modeling for Predicting Peak Stress Characteristics During Hot Deformation of Hot Isostatically Processed Nickel-Base Superalloy, J. Mater. Sci., 2015, 50(19), p 6444–6456. https://doi.org/10.1007/s10853-015-9200-0

J.J. Jonas, C.M. Sellars, W.J. Mc, and G. Tegart, Strength and Structure Hot-Working Conditions, Metall. Rev., 1969, 14, p 1–24. https://doi.org/10.1179/mtlr.1969.14.1.1

X. Xia, P. Sakaris, and H.J. McQueen, Hot Deformation, Dynamic Recovery, and Recrystallisation Behaviour of Aluminium 6061–SiCp Composite, Mater. Sci. Technol., 1994, 10(6), p 487–496. https://doi.org/10.1179/mst.1994.10.6.487

S.F. Medina and C.A. Hernandez, The Influence of Chemical Composition on Peak Strain of Deformed Austenite in Low Alloy and Microalloyed Steels, Acta Mater., 1996, 44(1), p 149–154. https://doi.org/10.1016/1359-6454(95)00151-0

Y. Wu, Z. Liu, X. Qin, C. Wang, and L. Zhou, Effect of Initial State on Hot Deformation and Dynamic Recrystallization of Ni-Fe Based Alloy GH984G for Steam Boiler Applications, J. Alloys Compounds, 2019, 795, p 370–384. https://doi.org/10.1016/j.jallcom.2019.05.022

Y.V.R.K. Prasad, and K.P. Rao, Processing Maps and Rate Controlling Mechanisms of Hot Deformation of Electrolytic Tough Pitch Copper in the Temperature Range 300-950 C, Mater. Sci. Eng. A, 2005, 391(1–2), p 141–150. https://doi.org/10.1016/j.msea.2004.08.049

Y.V.R.K. Prasad and K.P. Rao, Processing Maps for Hot Deformation of Rolled AZ31 Magnesium Alloy Plate: Anisotropy of Hot Workability, Mater. Sci. Eng. A, 2008, 487(1–2), p 316–327. https://doi.org/10.1016/j.msea.2007.10.038

L. Wei, Q. Pan, J. Zhou, K. Jia, and Z. Yin, Processing Maps and Flow Instability Analysis of Al-Zn-Mg-Cu-Zr Alloy, J. Central South Univ. (Sci. Technol.), 2013, 44(5), p 1798–1805.

V.V. Balasubrahmanyam and Y.V.R.K. Prasad, Deformation Behaviour of Beta Titanium Alloy Ti–10V–4.5 Fe–1.5 Al in Hot Upset Forging, Mater. Sci. Eng. A, 2002, 336(1–2), p 150–158.

Xu. Yan, Hu. Lianxin, T. Deng, and L. Ye, Hot Deformation Behavior and Processing Map of As-Cast AZ61 Magnesium Alloy, Mater. Sci. Eng., A, 2013, 559, p 528–533. https://doi.org/10.1016/j.msea.2012.08.137

N. Srinivasan and Y.V.R.K. Prasad, Characterisation of Dynamic Recrystallisation in Nickel Using Processing Map for Hot Deformation, Mater. Sci. Technol., 1992, 8(3), p 206–212. https://doi.org/10.1179/mst.1992.8.3.206

N. Ravichandran and Y.V.R.K. Prasad, Dynamic Recrystallization During Hot Deformation of Aluminum: A Study Using Processing Maps, Metall. Trans. A, 1991, 22(10), p 2339–2348. https://doi.org/10.1007/BF02665000

S.S. Satheesh Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, and U. Borah, Strain Rate Dependent Microstructural Evolution During Hot Deformation of a Hot Isostatically Processed Nickel Base Superalloy, J. Alloys Compounds, 2016, 681, p 28–42. https://doi.org/10.1016/j.jallcom.2016.04.185

Q.-Y. Yang, M. Ma, Y.-B. Tan, S. Xiang, F. Zhao, and Y.-L. Liang, Microstructure and Texture Evolution of TB8 Titanium Alloys During Hot Compression, Rare Met., 2021, 40, p 2917–2926. https://doi.org/10.1007/s12598-020-01643-7

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, and L.T. Li, EBSD Study of a Hot Deformed Nickel-Based Superalloy, J Alloys Compd., 2015, 640, p 101. https://doi.org/10.1016/j.jallcom.2015.04.008

Y.C. Lin, D.G. He, M.S. Chen, X.Y. Chen, C.Y. Zhao, X. Ma, and Z.L. Long, EBSD Analysis of Evolution of Dynamic Recrystallization Grains and δ Phase in a Nickel–Based Superalloy During Hot Compressive Deformation, Mater Des., 2016, 97, p 13. https://doi.org/10.1016/j.matdes.2016.02.052

H. Zhang, K. Zhang, S. Jiang, H. Zhou, C. Zhao, and X. Yang, Dynamic Recrystallization Behavior of a γ′-Hardened Nickel-Based Superalloy During Hot Deformation, J. Alloys Compounds, 2015, 623, p 374–385. https://doi.org/10.1016/j.jallcom.2014.11.056

Y. Wu, M. Zhang, X. Xie, F. Lin, and S. Zhao, Dynamic Recrystallization of a New Nickel-Based Alloy for 700 °C A-USC Power Plant Applications with Different Initial States: As-Homogenized and As-Forged, Mater. Sci. Eng. A, 2016, 662, p 283–295. https://doi.org/10.1016/j.msea.2016.03.074

Y. Wang, W.Z. Shao, L. Zhen, and X.M. Zhang, Microstructure Evolution During Dynamic Recrystallization of Hot Deformed Superalloy 718, Mater. Sci. Eng. A, 2008, 486, p 321–332. https://doi.org/10.1016/j.msea.2007.09.008

Acknowledgments

This study was funded by the Central Government Guides Local Science and Technology Development (Grant No. [2019] 4011), the Industrial and Information Development of Guizhou Province (Grant No. [2016] 034), and the Technology Development Project (Grant No. 2017033).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ling, M., Zhang, ZS., Liang, YL. et al. Hot-Working Properties of Ni-Based Superalloy GH4169 in Different Initial States. J. of Materi Eng and Perform 31, 6333–6348 (2022). https://doi.org/10.1007/s11665-022-06728-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06728-1