Abstract

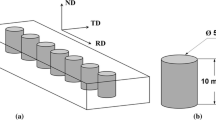

The hot compression behavior of AISI 321 austenitic stainless steel was studied at the temperatures of 950–1100°C and the strain rates of 0.01–1 s−1 using a Baehr DIL-805 deformation dilatometer. The hot deformation equations and the relationship between hot deformation parameters were obtained. It is found that strain rate and deformation temperature significantly influence the flow stress behavior of the steel. The work hardening rate and the peak value of flow stress increase with the decrease of deformation temperature and the increase of strain rate. In addition, the activation energy of deformation (Q) is calculated as 433.343 kJ/mol. The microstructural evolution during deformation indicates that, at the temperature of 950°C and the strain rate of 0.01 s−1, small circle-like precipitates form along grain boundaries; but at the temperatures above 950°C, the dissolution of such precipitates occurs. Energy-dispersive X-ray analyses indicate that the precipitates are complex carbides of Cr, Fe, Mn, Ni, and Ti.

Similar content being viewed by others

References

D. Peckner and I.M. Bernstein, Handbook of Stainless Steels, McGraw-Hill, New York, 1977, p. 48.

M. Chabaud-Reytier, L. Allais, C. Caes, P. Dubuisson, and A. Pineau, Mechanisms of stress relief cracking in titanium stabilised austenitic stainless steel, J. Nucl. Mater., 323(2003), p. 123.

K.S. Min, K.J. Kim, and S.W. Nam, Investigation of the effect of the types and densities of grain boundary carbides on grain boundary cavitation resistance of AISI 321 stainless steel under creep-fatigue interaction, J. Alloys Compd., 370(2004), p. 223.

K.S. Guan, X.D. Xu, Y.Y. Zhang, and Z.W. Wang, Cracks and precipitate phases in 321 stainless steel weld of flue gas pipe, Eng. Failure Anal., 12(2005), p. 623.

A. Pardo, M.C. Merino, A.E. Coy, F. Viejo, M. Carboneras, and R. Arrabal, Influence of Ti, C and N concentration on the intergranular corrosion behaviour of AISI 316Ti and 321 stainless steels, Acta Mater., 55(2007), p. 2239.

W.H. Zhang, J.L. Wu, Y.H. Wen, J.J. Ye, and N. Li, Characterization of different work hardening behavior in AISI 321 stainless steel and hadfield steel, J. Mater. Sci., 45(2010), p. 3433.

K.S. Guan, X.D. Xu, H. Xu, and Z.W. Wang, Effect of aging at 700°C on precipitation and toughness of AISI 321 and AISI 347 austenitic stainless steel welds, Nucl. Eng. Des., 235(2005), p. 2485.

R.C. de Sousa, J.C. Cardoso Filho, A.A. Tanaka, A.C.S. de Oliveira, and W.E.I. Ferreira, Effects of solution heat treatment on grain growth and degree of sensitization of AISI 321 austenitic stainless steel, J. Mater. Sci., 41(2006), No. 8, p. 2381.

V. Moura, A.Y. Kina, S.S.M. Tavares, L.D. Lima, and F.B. Mainier, Influence of stabilization heat treatments on microstructure, hardness and intergranular corrosion resistance of the AISI 321 stainless steel, J. Mater. Sci., 43(2008), p. 536.

K.D. Nair, Structure and strength during hot working of an austenitic steel, Metallography, 4(1971), p. 375.

L. Havela, P. Kratochvíl, P. Lukáč, B. Smola, and A. Svobodov á, Softening during and after the hot deformation of the AISI 321 steel with respect to practical applications, Czech. J. Phys. B, 38(1988), p. 384.

E.I. Poliak and J.J. Jonas, Initiation of dynamic recrystallization in constant strain rate hot deformation, ISIJ Int., 43(2003), No. 5, p. 684.

R. Herbertz and H. Wiegels, A method of performing the frictionless cylinder upsetting test for plotting stress-strain curves, Stahl Eisen., 101(1981), p. 89.

H. Mirzadeh, A. Najafizadeh, and M. Moazeny, Flow curve analysis of 17-4 PH stainless steel under hot compression test, Metall. Mater. Trans. A, 40(2009), p. 2950.

R. Ebrahimi and A. Najafizadeh, A new method for evaluation of friction in bulk metal forming, J. Mater. Process. Technol., 152(2004), p. 136.

H. Mirzadeh and A. Najafizadeh, Extrapolation of flow curves at hot working conditions, Mater. Sci. Eng. A, 527(2010), No. 7–8, p. 1856.

A. Najafizadeh and J.J. Jonas, Predicting the critical stress for initiation of dynamic recrystallization, ISIJ Int., 46(2006), No. 11, p. 1679.

A. Momeni, K. Dehghani, H. Keshmiri, and G.R. Ebrahimi, Hot deformation behavior and microstructural evolution of a superaustenitic stainless steel, Mater. Sci. Eng. A, 527(2010), p. 1605.

D.N. Zou, Y. Han, D.N. Yan, D. Wang, W. Zhang, and G.W. Fan, Hot workability of 00Cr13Ni5Mo2 supermartensitic stainless steel, Mater. Des., 32(2011), p. 4443.

C. Zener and J.H. Hollom, Effect of strain rate upon plastic flow of steel, J. Appl. Phys., 15(1944), p. 22.

A. Cingara and H.J. McQueen, New method for determining sinh constitutive constants for high temperature deformation of 300 austenitic steels, J. Mater. Process. Technol., 36(1992), p. 17.

H.J. McQueen and N.D. Ryan, Constitutive analysis in hot working, Mater. Sci. Eng. A, 322(2002), p. 43.

Y.C. Lin, M.S. Chen, and J. Zhong, Constitutive modeling for elevated temperature flow behavior of 42CrMo steel, Comput. Mater. Sci., 42(2008), p. 470.

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, and K.V. Kasiviswanathan, Constitutive equations to predict high temperature flow stress in a Ti-modified austenitic stainless steel, Mater. Sci. Eng. A, 500(2009), p. 114.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haj, M., Mansouri, H., Vafaei, R. et al. Hot compression deformation behavior of AISI 321 austenitic stainless steel. Int J Miner Metall Mater 20, 529–534 (2013). https://doi.org/10.1007/s12613-013-0761-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0761-0