Abstract

This study investigates the influence of high-current pulsed electron beam (HCPEB) modification on the microstructure and shear strength of Cu/CuW joints. Reliable solid-state diffusion bonding of modified-Cu (M-Cu) and modified-CuW (M-CuW) was achieved by HCPEB modification pretreatment at a temperature of 800–900 °C and a pressure of 5 MPa for 10–50 min. Experiments demonstrate that HCPEB modification facilitates the dissolution of W and Cu, resulting in the formation of a Cu0.4W0.6 solid solution and thus enhancing the uniform distribution of microstructures. Additionally, HCPEB-induced defects play a beneficial role in promoting the diffusion process by providing fast diffusion paths for elements. The optimal joints with the maximum shear strength of 213.7 MPa were obtained through bonding M-Cu and M-CuW at 900 °C and 5 MPa for 30 min, which attributes to the combined effects of fine-grained strengthening and solid solution strengthening. Overall, the application of HCPEB modification showcases its effectiveness in promoting element diffusion and enhancing the mechanical performance of the joints.

Graphical abstract

摘要

我们研究了强流脉冲电子束(HCPEB)改性对Cu/CuW接头微结构和剪切强度的影响。对HCPEB改性预处理后的样品,在800–900 ℃的温度条件下施加5 MPa的压力,进行10–50 min的保温,实现了M-Cu和M-CuW的固态扩散焊接。实验结果表明,HCPEB改性有助于W和Cu的固溶,形成均匀分布的Cu0.4W0.6。此外,HCPEB诱导的丰富晶体缺陷促进了焊接过程的进行,为元素提供快速扩散路径。通过在900 ℃温度下施加5 MPa的压力保温30 min的条件下连接M-Cu和M-CuW,得到了剪切强度为213.7 MPa的最佳接头。接头性能的提升归因于细晶强化和固溶体强化。综上所述,HCPEB表面改性促进了元素扩散和并有效提高了接头力学性能。

Similar content being viewed by others

References

Wang CC, Jia CC, Gao P, Gai GS, Yang YF. Spherical modification of tungsten powder by particle composite system. Rare Met. 2022;41(6):1972. https://doi.org/10.1007/s12598-015-0546-x.

Cheng C, Song ZW, Wang LF, Song KX, Huang T, Zhao L, Wang LS, Dou ZH, Zhang TA. Novel synthesis of CuW composite reinforced with lamellar precipitates via aluminothermic reduction. Rare Met. 2022;41(12):4075. https://doi.org/10.1007/s12598-022-02092-0.

Zhang YY, Xiong N, Wang XB, Yang HC, Chen FG, Liu XG. Research progress of tungsten and tungsten alloys prepared by additive manufacturing technology. Chin J Rare Met. 2023,47(5):329. https://doi.org/10.13373/j.cnki.cjrm.XY22120015.

Zhan JP, Feng XM, Shen YF, Chen C, Dua CY. Microstructures and properties of Cu-Cr-W composite coatings fabricated by surface mechanical alloying technique. Rare Met. 2022;41(12):424. https://doi.org/10.1007/s12598-016-0843-z.

Dong BW, Wu ZP, Jie JC, Kang HJ, Li TJ. Microstructure and ablation resistance mechanism of Cu–W alloy used for electrical contacts. Copp Eng. 2023;(4):63. https://doi.org/10.3969/j.issn.1009–3842.2023.04.008.

Jiang DF, Long JY, Cai MY, Lin Y, Fan PX, Zhang HJ. Femtosecond laser fabricated micro/nano interface structures toward enhanced bonding strength and heat transfer capability of W/Cu joining. Mater Des. 2017;114:185. https://doi.org/10.1016/j.matdes.2016.11.094.

Yan HX, Fan JL, Han Y, Yao Q, Liu T, Lv YQ, Zhang CG. Vacuum diffusion bonding W to W-Cu composite: interfacial microstructure and mechanical properties. Vacuum. 2019;165:19. https://doi.org/10.1016/j.vacuum.2019.03.060.

Chen YY, Huang Y, Han L, Liu DG, Luo LM, Li CX, Wang ZM. High-strength vacuum diffusion bonding of Cu-plated, sandblasted W and CuCrZr alloy. J Mater Res Technol. 2021;15:6260. https://doi.org/10.1016/j.jmrt.2021.11.069.

Zou J, Song D, Shi H, Liang S. Effects of grading tungsten powders on properties of CuW alloy. Mater Res Express. 2020;7(2): 026528. https://doi.org/10.1088/2053-1591/ab6e31.

Xiu L, Wu JF. Atomic diffusion behavior in W/Cu diffusion bonding process. J Fusion Energy. 2015;34(4):769. https://doi.org/10.1007/s10894-015-9884-9.

Han J, Sheng GM, Zhou XL. Diffusion bonding of surface self-nanocrystallized Ti-4Al-2V and 0Cr18Ni9Ti by means of high energy shot peening. ISIJ Int. 2008;48(9):1238. https://doi.org/10.2355/isijinternational.48.1238.

Luo J, Guang SM, Yuan XJ. Diffusion bonding of SSNC 304L/Cu. J Cent South Univ. 2013;44(01):55.

Tian NN, Li SW, Zhang CL, Cai J, Lyu P, Konovalov S, Chen XZ, Peng CT, Guan QF. The surface modification of aluminum by mechanical milling of Pb coating and high current pulsed electron beam irradiation. Mater Res Express. 2019;6(12):1265g3. https://doi.org/10.1088/2053-1591/ab6769.

Zhang CL, Cai J, Lv P, Zhang YH, Xia H, Guan QF. Surface microstructure and properties of Cu-C powder metallurgical alloy induced by high-current pulsed electron beam. J Alloys Compd. 2017;697:96. https://doi.org/10.1016/j.jallcom.2016.12.119.

Zhang CL, Gao Q, Lv P, Cai J, Peng CT, Jin YX, Guan QF. Surface modification of Cu-W powder metallurgical alloy induced by high-current pulsed electron beam. Powder Technol. 2018;325:340. https://doi.org/10.1016/j.powtec.2017.11.037.

Grosdidier T, Zou JX, Stein N, Boulanger C, Hao SZ, Dong C. Texture modification, grain refinement and improved hardness/corrosion balance of a FeAl alloy by pulsed electron beam surface treatment in the “heating mode”. Scr Mater. 2008;58(12):1058. https://doi.org/10.1016/j.scriptamat.2008.01.052.

Fan XR, Fan SY, Xie L, Huang ZW, Gao MQ, Li YT, Li Q, Wang AD. Structure properties of Fe–based metallic glasses with different Cu addition. Copper Engineering. 2023(2):15. https://doi.org/10.3969/j.issn.1009–3842.2023.02.003.

Tian NN, Ji XS, Zhang CL, Lv P, Guan JT, Cai J, Guan QF. Influence of high-current pulsed electron beam irradiation on elemental diffusion and mechanical properties of copper/316L stainless-steel bonded joints. Nucl Instruments Methods Phys Res Sect B Beam Interact with Mater Atoms. 2022;531:115. https://doi.org/10.1016/j.nimb.2022.09.021.

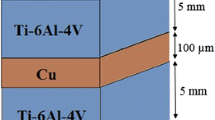

Tian NN, Guan JT, Zhang CL, Lyu P, Peng CT, Cai J, Guan QF. Influence of high-current pulsed electron beam irradiation on element diffusion behavior and mechanical properties of TC4/304 stainless steel diffusion bonded joints. Mater Charact. 2023;1998;74(3):131. https://doi.org/10.1016/J.MATCHAR.2023.112713.

Hÿtch MJ, Snoeck E, Kilaas R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy. 1998;74(3):131. https://doi.org/10.1016/S0304-3991(98)00035-7.

Zhang CL, Lv P, Xia H, Yang ZR, Konovalov S, Chen XZ, Guan QF. The microstructure and properties of nanostructured Cr-Al alloying layer fabricated by high-current pulsed electron beam. Vacuum. 2019;167:263. https://doi.org/10.1016/j.vacuum.2019.06.022.

Wen SP, Zong RL, Zeng F, Gao Y, Pan F. Evaluating modulus and hardness enhancement in evaporated Cu/W multilayers. Acta Mater. 2007;55(1):345. https://doi.org/10.1016/j.actamat.2006.07.043.

Xu L, Yan M, Xia Y, Peng JH, Li W, Zhang LB, Liu CH, Chen G, Li Y. Influence of copper content on the property of Cu-W alloy prepared by microwave vacuum infiltration sintering. J Alloys Compd. 2014;592:202. https://doi.org/10.1016/j.jallcom.2013.12.202.

Dong BW, Wu ZP, Jie JC, Kang HJ, Li TJ. Microstructure and ablation resistance mechanism of Cu–W alloy used for electrical contacts. Copper Engineering. 2023(4):63. https://doi.org/10.3969/j.issn.1009–3842.2023.04.008.

Zhang HB, Liu T, Han Y, Lu YZ, Zhao SQ, Tian JM, Tang SS, Xu ZY, Lu Q, Fan JL. Supersaturated W-Cu nanocomposites with outstanding strength-ductility synergy. Mater Sci Eng A. 2023;874:144578. https://doi.org/10.1016/j.msea.2023.144578.

Taylor P, Williamson GK, Smallman RE III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philosophical magazine. 1956;1:34. https://doi.org/10.1080/14786435608238074.

Zhang CL, Lv P, Cai J, Peng CT, Jin Y, Guan QF. The microstructure and properties of tungsten alloying layer on copper by high-current pulse electron beam. Appl Surf Sci. 2017;422:582. https://doi.org/10.1016/j.apsusc.2017.06.049.

Zhao L, Hu LW, Wang D, Liu X. Microstructure and mechanical properties of Cu–Fe alloy prepared by laser melting deposition. Copper Engineering. 2023(2):44. https://doi.org/10.3969/j.issn.1009–3842.2023.02.006.

Lv P, Xu J, Yang R, Zhang C, Zhang F, Dong S, Guan QF. Effect of thermocycling on the microstructure of Ti-6Al-4V alloy in simulated low Earth orbit space environment. Sci China Mater. 2016;59(5):363. https://doi.org/10.1007/s40843-016-5029-9.

Xia H, Zhang CL, Lv P, Cai J, Jin YX, Guan QF. Surface alloying of aluminum with molybdenum by high-current pulsed electron beam. Nucl Instruments Methods Phys Res Sect B Beam Interact with Mater Atoms. 2018;416:9. https://doi.org/10.1016/j.nimb.2017.11.028.

Wirth LJ, Farajian AA, Woodward C. Density functional study of self-diffusion along an isolated screw dislocation in fcc Ni. Phys Rev Mater. 2019;3(3):1. https://doi.org/10.1103/PhysRevMaterials.3.033605.

Zhang LY, Peng CT, Guan JT, Lv P, Guan QF, Lu R. Nanocrystalline Cr-Ni alloying layer induced by high-current pulsed electron beam. Nanomaterials. 2019;9(1):74. https://doi.org/10.3390/nano9010074.

Lee SH, Jung JG, Baik SI, Seidman DN, Kim MS, Lee YK, Euh K. Precipitation strengthening in naturally aged Al–Zn–Mg–Cu alloy. Mater Sci Eng: A. 2021;803:140719. https://doi.org/10.1016/j.msea.2020.140719.

Yilmaz O, Aksoy M. Investigation of micro-crack occurrence conditions in diffusion bonded Cu-304 stainless steel couple. J Mater Process Technol. 2002;121(1):136. https://doi.org/10.1016/S0924-0136(01)01224-9.

Guo H, Rao M, Zhang J, Wang X, Luo G, Shen Q. Electromigration-enhanced Kirkendall effect of Cu / Ti direct diffusion welding by sparking plasma sintering. J Mater Process Tech. 2023;315:117933. https://doi.org/10.1016/j.jmatprotec.2023.117933.

Liu CM, Lin HW, Huang YS, Chu YC, Chen C, Lyu DR, Chen KN, Tu KN. Low-temperature direct copper-to-copper bonding enabled by creep on (111) surfaces of nanotwinned Cu. Sci Rep. 2015;5:1. https://doi.org/10.1038/srep09734.

Lyu P, Chen YN, Liu ZJ, Peng CT, Cai J, Zhang CL, Jin YX, Guan QF. The effect of high current pulsed electron beam irradiation on microstructure and properties Cu-Fe powder metallurgical alloys. Mater Res Express. 2019;6:126520. https://doi.org/10.1088/2053-1591/ab5514.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 52001273) and the Natural Science Foundation of Jiangsu Province (No. BK20201062).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tian, NN., Zhang, CL., Lyu, P. et al. High-current pulsed electron beam modification on microstructure and performance of Cu/CuW diffusion bonding joints. Rare Met. 43, 2819–2831 (2024). https://doi.org/10.1007/s12598-024-02617-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-024-02617-9