Abstract

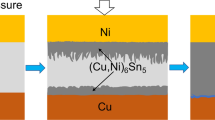

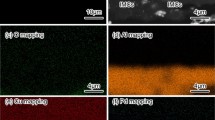

Diffusion bonding between Al and Cu was successfully performed by hot isostatic pressing (HIP). To improve the strength of diffusion bonding joint, pure nickel foils with different thickness were used as intermediate layer. Microstructure of the interface between Al and Cu was investigated by X-ray diffraction (XRD) technique, secondary electron microscopy (SEM), and nano-indentation tests. When the temperature was 500 °C and held for 3 h with a processing pressure of 50 MPa, Al and Cu could be bonded with its interface formed by several diffusion layers. With the addition of Ni interlayer, the diffusion of aluminum atoms was effectively hindered, and the interface became smoother. The tensile strength of bonded joints increases with increasing the thickness of Ni interlayer, which contributes to a reduction in the thickness of intermetallic compounds (IMCs) and well bonding quality of Al-Cu joints.

Similar content being viewed by others

References

Jr E A S, Williams J C. Progress in Structural Materials for Aerospace Systems1[J]. Acta Mater., 2003, 51(19): 5 775–5 799

Liu C H, Li X L, Wang S H, et al. A Tuning Nano-precipitation Approach for Achieving Enhanced Strength and Good Ductility in Al Alloys[J]. Mater. Des., 54: 144–148

Li H, Chen W, Dong L, et al. Interfacial Bonding Mechanism and Annealing Effect on Cu-Al Joint Produced by Solid-Liquid Compound Casting[J]. J. Mater. Process. Technol., 2018, 252: 795–803

Berski S, Banaszek G, Dyja H. Analysis of Die Shape Infuence on Al-Cu Bimetal Charge Yield during Extrusion Process[J]. Metall. Min. Ind., 2011, 3(7): 45–47

Berski S, Dyja H, Maranda A, et al. Analysis of Quality of Bimetallic Rod after Extrusion Process[J]. J. Mater. Process. Technol., 2006, 177(1–3): 582–586

Khosravifard A, Ebrahimi R. Investigation of Parameters Affecting Interface Strength in Al/Cu Clad Bimetal Rod Extrusion Process[J]. Mater. Des., 2010, 31(1): 493–499

Dubourg L, Pelletier H, Vaissiere D, et al. Cornet. Mechanical Characterisation of Laser Surface Alloyed Aluminium–Copper Systems[J]. Wear, 2002, 253(9–10): 1 077–1 085

Yuan H U, Chen Y Q, Li L, et al. Microstructure and Properties of Al/ Cu Bimetal in Liquid–Solid Compound Casting Process[J]. T. Nonferr. Metal. Soc., 2016, 26(6): 1 555–1 563

Zhang L Y, Yao J J, Zeng X Y, et al. Research Progress of Copper Cladding Aluminum Composites[J]. T. Nonferr. Metal. Soc., 2014, 24(5): 1 275–1 284

Hug E, Bellido N. Brittleness Study of Intermetallic (Cu, Al) Layers in Copper-Clad Aluminium Thin Wires[J]. Mater. Sci. Eng., A, 2011, 528(22): 7 103–7 106

Lee W B, Bang K S, Jung S B. Effects of Intermetallic Compound on the Electrical and Mechanical Properties of Friction Welded Cu/Al Bimetallic Joints during Annealing[J]. J. Alloys Compd., 2005, 390(1): 212–219

Tavassoli S, Abbasi M, Tahavvori R. Controlling of IMCs Layers Formation Sequence, Bond Strength and Electrical Resistance in Al-Cu Bimetal Compound Casting Process[J]. Mater. Des., 2016, 108: 343–353

Abbasi M, Taheri A K, Salehi M T. Growth Rate of Intermetallic Compounds in Al/Cu Bimetal Produced by Cold Roll Welding Process[J]. J. Alloys Compd., 2001, 319(1–2): 233–241

Zare G R, Divandari M, Arabi H. Investigation On Interface of Al/Cu Couples in Compound Casting[J]. Mater. Sci. Technol., 2013, 29(2): 190–196

Xia C Z, Li Y J, Wang J. Microstructure and Phase Constitution Near Interface of Cu/Al Vacuum Brazing[J]. Vacuum, 2008, 82(8): 799–804

Niu Z W, Zheng Y, Liu K K, et al. Microstructure and Property of Cu/Al Joint Brazed with Al-Si-Ge Filler Metal[J]. Acta Metall. Sinica, 2017, 53(6): 719–725

Zhang H, Wei C, He J, et al. Formation and Evolution of Cntermetallic Compounds at Interfaces of Cu/Al Joints by Ultrasonic-Assisted Sol-dering[J]. J. Mater. Process. Technol., 2015, 223: 1–7

Guo Y, Liu G, Jin H, et al. Intermetallic Phase Formation in Diffusion-bonded Cu/Al Laminates[J]. J. Mater. Sci., 2011, 46(8): 2 467–2 473

Mahendran G, Balasubramanian V, Senthilvelan T. Mechanical and Metallurgical Properties of Diffusion Bonded AA2024 Al and AZ31B Mg[J]. Adv. Mater. Res., 2012, 1(2): 147–160

Meng Z H, Wang X, Guo W, et al. Joining Performance and Microstructure of the 2024/7075 Aluminium Alloys Welded Joints by Vaporizing Foil Actuator Welding[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2019, 34(2): 368–372

Feng J, Xue S. Growth Behaviors of Intermetallic Compound Layers in Cu/Al Joints Brazed with Zn–22Al and Zn–22Al–0.05Ce Filler Met-als[J]. Mater. Des., 2013, 51(5): 907–915

Lee T H, Lee Y J, Park K T, et al. Controlling Al/Cu Composite Diffusion Layer during Hydrostatic Extrusion by Using Colloidal Ag[J]. J. Mater. Process. Technol., 2013, 213(3): 487–494

Meshram S D, Reddy G M. Friction Welding of AA6061 to AISI 4340 Using Silver Interlayer[J]. Def. Technol., 2015, 11(3): 292–298

Kuk S W, Ryu H J, Yu J. Effects of the Al/Ni Ratio on the Reactions in the Compression-bonded Ni-Sputtered Al Foil Multilayer[J]. J. Alloys Compd., 2014, 589(4): 455–461

Kuk S W, Ryu H J, Yu J. Self-propagation Combustion Behavior with Varying Al/Ni Ratios in Compression-Bonded Ni-Sputtered Al Foil Multilayers[J]. Metall. Mater. Trans. A, 2014, 45(12): 5 691–5 698

Kuk S W, Yu J, Ryu H J. Stationary Self-Propagation Combustion with Variations in the Total Layer Thickness of Compression-Bonded Ni-Sputtered Al Foil Multilayers[J]. J. Alloys Compd., 2015, 626: 16–19

Li H Y, Chen W G, Dong L L, et al. Interfacial Bonding Mechanism and Annealing Effect on Cu-Al Joint Produced by Solid-Liquid Compound Casting[J]. J. Mater. Process. Technol., 2017, 252: 795–803

Kim I K, Sun I H. Effect of Heat Treatment on the Bending Behavior of Tri-layered Cu/Al/Cu Composite Plates[J]. Mater. Des., 2013, 47(9): 590–598

Sheng L Y, Yang F, Xi T F, et al. Infuence of Heat Treatment on Interface of Cu/Al Bimetal Composite Fabricated by Cold Rolling[J]. Composites Part B, 2011, 42(6): 1 468–1 473

Zhang R, Lin G, Wang L, et al. Effect of Heat Treatment on the Interface of Al/Cu Bimetal Laminated Material[J]. Ordnance Mater. Sci. Eng., 2011, 34(5): 5–8

Zhang Y H, Qin J, Zhao H J, et al. Interfacial Microstructure Evolution of Copper/Aluminium Laminates with Different Annealing Pro-cesses[J]. Adv. Mater. Res., 2011, 239–242: 2 976–2 980

Abdul-Lettif A M. Investigation of Interdiffusion in Copper–Nickel Bilayer Thin Films[J]. Physica B, 2007, 388(1–2): 107–111

Xiong J, Peng Y, Zhang H, et al. Microstructure and Mechanical Properties of Al-Cu Joints Diffusion-bonded with Ni or Ag Interlayer[J]. Vacuum, 2018, 147: 187–193

Lee S., Lee M G, Lee S P, et al. Effect of Bonding Interface on De-lamination Behavior of Drawn Cu/Al Bar Clad Material[J]. T. Nonferr. Metal. Soc., 2012, 22: 645–649

Qi J L, Wang Z Y, Lin J H, et al. Graphene-Enhanced Cu Composite Interlayer for Contact Reaction Brazing Aluminum Alloy 6061[J]. Va c -uum, 2017, 136: 142–145

Zhang H T, Cao J, Lu H. Reactive Brazing of Aluminium to Aluminium-Based Composite Reinforced with Alumina Borate Whiskers with Cu Interlayer[J]. Vacuum, 2009, 84(4): 474–477

Yousef Mehr V, Toroghinejad M R, Rezaeian A. The Effects of Oxide Film and Annealing Treatment on the Bond Strength of Al–Cu Strips in Cold Roll Bonding Process[J]. Mater. Des., 2014, 53: 174–181

Ling C, Zhong Y, Chen Y, et al. Fabrication of Lateral Compound Cu/ Al Composites by Conclad Continuous Extrusion[J]. Spec.Cast. Non-ferr. Alloys, 2017, 37(1): 89–93

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by National Science and Technology Major Project (No. 2017-V I-0009-0080), Science and Technology Planning Project of Wuhan (No. 2018010401011281)

Rights and permissions

About this article

Cite this article

Teng, Q., Li, X. & Wei, Q. Diffusion Bonding of Al 6061 and Cu by Hot Isostatic Pressing. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 183–191 (2020). https://doi.org/10.1007/s11595-020-2242-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2242-4