Abstract

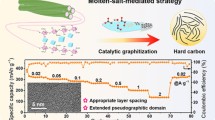

Hard carbon (HC) is broadly recognized as an exceptionally prospective candidate for the anodes of sodium-ion batteries (SIBs), but their practical implementation faces substantial limitations linked to precursor factors, such as reduced carbon yield and increased cost. Herein, a cost-effective approach is proposed to prepare a coal-derived HC anode with simple pre-oxidation followed by a post-carbonization process which effectively expands the d002 layer spacing, generates closed pores and increases defect sites. Through these modifications, the resulting HC anode attains a delicate equilibrium between plateau capacity and sloping capacity, showcasing a remarkable reversible capacity of 306.3 mAh·g−1 at 0.03 A·g−1. Furthermore, the produced HC exhibits fast reaction kinetics and exceptional rate performance, achieving a capacity of 289 mAh·g−1 at 0.1 A·g−1, equivalent to ~ 94.5% of that at 0.03 A·g−1. When implemented in a full cell configuration, the impressive electrochemical performance is evident, with a notable energy density of 410.6 Wh·kg−1 (based on cathode mass). In short, we provide a straightforward yet efficient method for regulating coal-derived HC, which is crucial for the widespread use of SIBs anodes.

Graphical abstract

摘要

虽然硬碳(HC)被广泛认为是钠离子电池(SIB)负极极具前景的候选材料,但在实际应用中却面临着与前驱体因素相关的巨大限制,如低残炭率和较高成本。本文提出了一种低成本高效益的方法,通过简单的预氧化和后碳化工艺制备煤基硬碳负极,该策略可有效扩大 d002 层间距、产生封闭孔隙并增加缺陷位点。通过结构优化,所制备的硬碳负极的高电势区容量和低压区容量之间达到了微妙的平衡,在 0.03 A·g−1 的电流密度下展现出 306.3 mAh·g−1 的高可逆容量。此外,制备的硬碳负极还具有快速的反应动力学和优异的倍率性能,在 0.1 A·g−1 的电流密度下容量可达到 289 mAh·g−1,约为 0.03 A·g−1 条件下容量的 94.5%。当匹配成全电池时电化学性能优异,能量密度高达 410.6 Wh·kg−1(基于正极质量)。总之,我们提供了一种简单有效的方法制备煤基硬碳负极,这对于大规模生产SIBs负极材料至关重要。

Similar content being viewed by others

References

Hwang JY, Myung ST, Sun YK. Sodium-ion batteries: present and future. Chem Soc Rev. 2017;46:3529. https://doi.org/10.1039/C6CS00776G.

Kang J, Zhu L, Teng FY, Wang SQ, Huang YG, Xiang YH, Chen Z, Wu XW. High-rate performance and super long-cycle stability of Na3V2(PO4)3 cathode material coated by diatomic doped carbon. Rare Met. 2023;42(5):1570. https://doi.org/10.1007/s12598-022-02204-w.

Xu YF, Ding TJ, Sun DM, Ji XL, Zhou XS. Recent advances in electrolytes for potassium-ion batteries. Adv Func Mater. 2023;33:2211290. https://doi.org/10.1002/adfm.202211290.

Du YC, Zhang ZZ, Xu YF, Bao JC, Zhou XS. Metal sulfide-based potassium-ion battery anodes: storage mechanisms and synthesis strategies. Acta Phys Chim Sin. 2022;38:2205017. https://doi.org/10.3866/PKU.WHXB202205017.

Zhang ZJ, Sun HY, Chen YF, Zhao YW, Zhang MM, Li CS, Sun Y, Gao ZH, Li HJ, Jiang Y. Modulating p-d orbital hybridization by CuO/Cu nanoparticles enables carbon nanofibers high cycling stability as anode for sodium storage. Rare Met. 2023. https://doi.org/10.1007/s12598-023-02449.

Xie F, Xu Z, Guo Z, Titirici MM. Hard carbons for sodium-ion batteries and beyond. Progress Energy. 2020;2:042002. https://doi.org/10.1088/2516-1083/aba5f5.

Li LY, Huang FB, Deng J, Liu P, Wang F, Yao QR, Wang ZM, Zhou HY, Deng JQ. Realizing remarkable sodium storage performance of a Sn-based anode material with an oxide-alloy intergrowth structure. Rare Met. 2022;41(5):1512. https://doi.org/10.1007/s12598-021-01923-w.

Huang ZX, Zhang XL, Zhao XX, Lü HY, Zhang XY, Heng YL, Geng H, Wu XL. Suppressing oxygen redox in layered oxide cathode of sodium-ion batteries with ribbon superstructure and solid-solution behavior. J Mater Sci Technol. 2023;160:9. https://doi.org/10.1016/j.jmst.2023.04.002.

Wang T, Huang Z, Wang D, Wu J, Lu J, Jin Z, Shi S, Zhang Y. PxSy nanoparticles encapsulated in graphene as highly reversible cathode for sodium ion batteries. Chin Chem Lett. 2023;34:107216. https://doi.org/10.1016/j.cclet.2022.02.021.

Li J, Hu H, Wang J, Xiao Y. Surface chemistry engineering f layered oxide cathodes for sodium-ion batteries. Carbon Neutr. 2022;1:96. https://doi.org/10.1002/cnl2.19.

Voronina N, Myung ST. Recent advances in electrode materials with anion redox chemistry for sodium-ion batteries. Energy Mater Adv. 2021;2021:9819521. https://doi.org/10.34133/2021/9819521.

Chen B, Yang Y, Chen A, Zhang X, Saddique J, Tang M, Yu H. Sodium-ion battery anode construction with SnPx crystal domain in amorphous phosphorus matrix. Energy Mater Adv. 2021;2021:9795825. https://doi.org/10.34133/2021/9795825.

Yan D, Xiao S, Li X, Jiang J, He Q, Li H, Qin J, Wu R, Niu X, Chen JS. NiS2/FeS heterostructured nanoflowers for high-performance sodium storage. Energy Mater Adv. 2023;4:0012. https://doi.org/10.34133/energymatadv.0012.

Li Y, Lai XQ, Qu JP, Lai QZ, Yi TF. Research progress in regulation strategies of high-performance antimony-based anode materials for sodium ion batteries. Acta Phys Chim Sin. 2022;38:2204049. https://doi.org/10.3866/PKU.WHXB202204049.

Zhang XL, Huang ZX, Liu YN, Su MY, Li K, Wu XL. Tuning oxygen release of sodium-ion layered oxide cathode through synergistic surface coating and doping. J Colloid Interface Sci. 2023;650:742. https://doi.org/10.1016/j.jcis.2023.06.201.

Kumar Prajapati A, Bhatnagar A. A review on anode materials for lithium/sodium-ion batteries. J Energy Chem. 2023;83:509. https://doi.org/10.1016/j.jechem.2023.04.043.

Fu YH, Peng YY, Zhao L, He TQ, Yuan MM, Dang H, Liu R, Ran F. Vanadium nitride quantum dots@carbon skeleton anode material synthesized via in situ oxidation initiation strategy. Tungsten. 2023. https://doi.org/10.1007/s42864-023-00246-w.

Liu TT, Li ZL, Gu YY, Duan CQ, Zhang ZJ. Research progress of Cu doping in sodium–ion battery cathode. Copper Engineering, 2023(4):14. https://doi.org/10.3969/j.issn.1009–3842.2023.04.002

Zhang W, Zhang F, Ming F, Alshareef HN. Sodium-ion battery anodes: Status and future trends. EnergyChem. 2019;1:100012. https://doi.org/10.1016/j.enchem.2019.100012.

Yu P, Tang W, Wu FF, Zhang C, Luo HY, Liu H, Wang ZG. Recent progress in plant-derived hard carbon anode materials for sodium-ion batteries: a review. Rare Met. 2020;39(9):1019. https://doi.org/10.1007/s12598-020-01443-z.

Zhang R, Raveendran V, He Y, Yau A, Chang A, Chi C, Bong S, Cheng F, Ma W, Chen J. A poriferous nanoflake-assembled flower-like Ni5P4 anode for high-performance sodium-ion batteries. Energy Mater Adv. 2021;2021:2124862. https://doi.org/10.34133/2021/2124862.

Lu Z, Wang J, Feng W, Yin X, Feng X, Zhao S, Li C, Wang R, Huang QA, Zhao Y. Zinc single-atom-regulated hard carbons for high-rate and low-temperature sodium-ion batteries. Adv Mater. 2023;35:2211461. https://doi.org/10.1002/adma.202211461.

Yu K, Zhao H, Wang X, Zhang M, Dong R, Li Y, Bai Y, Xu H, Wu C. Hyperaccumulation route to Ca-rich hard carbon materials with cation self-incorporation and interlayer spacing optimization for high-performance sodium-ion batteries. ACS Appl Mater Interfaces. 2020;12(9):10544. https://doi.org/10.1021/acsami.9b22745.

Chen X, Liu C, Fang Y, Ai X, Zhong F, Yang H, Cao Y. Understanding of the sodium storage mechanism in hard carbon anodes. Carbon Energy. 2022;4:1133. https://doi.org/10.1002/cey2.196.

Dong R, Wu F, Bai Y, Li Q, Yu X, Li Y, Ni Q, Wu C. Tailoring defects in hard carbon anode towards enhanced Na storage performance. Energy Mater Adv. 2022;2022:9896218. https://doi.org/10.34133/2022/9896218.

Dou X, Hasa I, Saurel D, Vaalma C, Wu L, Buchholz D, Bresser D, Komaba S, Passerini S. Hard carbons for sodium-ion batteries: structure, analysis, sustainability, and electrochemistry. Mater Today. 2019;23:87. https://doi.org/10.1016/j.mattod.2018.12.040.

Sun F, Wang H, Qu Z, Wang K, Wang L, Gao J, Gao J, Liu S, Lu Y. Carboxyl-dominant oxygen rich carbon for improved sodium ion storage: synergistic enhancement of adsorption and intercalation mechanisms. Adv Energy Mater. 2021;11:2002981. https://doi.org/10.1002/aenm.202002981.

Zhang X, Zhang S, Li P, Ding Z, Hao Z. Investigation on solubility of multicomponent from semi-anthracite coal and its effect on coal structure by Fourier transform infrared spectroscopy and X-ray diffraction. Fuel Process Technol. 2018;174:123. https://doi.org/10.1016/j.fuproc.2018.02.018.

Wang JP, Li GY, Guo R, Li AQ, Liang YH. Theoretical and experimental insight into coal structure: establishing a chemical model for Yuzhou lignite. Energy Fuels. 2017;31:124. https://doi.org/10.1021/acs.energyfuels.6b01854.

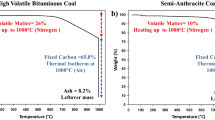

Wang K, Sun F, Wang H, Wu D, Chao Y, Gao J, Zhao G. Altering thermal transformation pathway to create closed pores in coal-derived hard carbon and boosting of Na+ plateau storage for high-performance sodium-ion battery and sodium-ion capacitor. Adv Func Mater. 2022;32:2203725. https://doi.org/10.1002/adfm.202203725.

Lu H, Sun S, Xiao L, Qian J, Ai X, Yang H, Lu AH, Cao Y. High-capacity hard carbon pyrolyzed from subbituminous coal as anode for sodium-ion batteries. ACS Appl Energy Mater. 2019;2:729. https://doi.org/10.1021/acsaem.8b01784.

Li Y, Hu YS, Qi X, Rong X, Li H, Huang X, Chen L. Advanced sodium-ion batteries using superior low cost pyrolyzed anthracite anode: towards practical applications. Energy Storage Mater. 2016;5:191. https://doi.org/10.1016/j.ensm.2016.07.006.

Chen H, Sun N, Zhu Q, Soomro RA, Xu B. Microcrystalline hybridization enhanced coal-based carbon anode for advanced sodium-ion batteries. Adv Sci. 2022;9:2200023. https://doi.org/10.1002/advs.202200023.

Zhao H, Zhao D, Ye J, Wang P, Chai M, Li Z. Directional oxygen functionalization by defect in different metamorphic-grade coal-derived carbon materials for sodium storage. Energy Environ Mater. 2022;5:313. https://doi.org/10.1002/eem2.12178.

Sun N, Qiu J, Xu B. Understanding of sodium storage mechanism in hard carbons: ongoing development under debate. Adv Energy Mater. 2022;12:2200715. https://doi.org/10.1002/aenm.202200715.

Yu K, Wang X, Yang H, Bai Y, Wu C. Insight to defects regulation on sugarcane waste-derived hard carbon anode for sodium-ion batteries. J Energy Chem. 2021;55:499. https://doi.org/10.1016/j.jechem.2020.07.025.

Wang Q, Zhu X, Liu Y, Fang Y, Zhou X, Bao J. Rice husk-derived hard carbons as high-performance anode materials for sodium-ion batteries. Carbon. 2018;127:658. https://doi.org/10.1016/j.carbon.2017.11.054.

Sun Y, Lu P, Liang X, Chen C, Xiang H. High-yield microstructure-controlled amorphous carbon anode materials through a pre-oxidation strategy for sodium ion batteries. J Alloy Compd. 2019;786:468. https://doi.org/10.1016/j.jallcom.2019.01.388.

Lu Y, Zhao C, Qi X, Qi Y, Li H, Huang X, Chen L, Hu YS. Pre-oxidation-tuned microstructures of carbon anodes derived from pitch for enhancing Na storage performance. Adv Energy Mater. 2018;8:1800108. https://doi.org/10.1002/aenm.201800108.

Wang G, Zhou A. Time evolution of coal structure during low temperature air oxidation. Int J Min Sci Technol. 2012;22:517. https://doi.org/10.1016/j.ijmst.2012.01.013.

Wang CP, Deng J, Wang K. Infrared spectrum characteristics of active groups during oxidation process for different ranks of coal. J Xi’an Univ Sci Technol. 2016;36:320. https://doi.org/10.13800/j.cnki.xakjdxxb.2016.0304.

Chen J, Wang YG, Wang ZL, Shen J, Niu YX, Liu G, Sheng QT. Research progress and prospects of mild oxidative depolymerization of low-rank coals. Clean Coal Technol. 2022;28:133. https://doi.org/10.13226/j.issn.1006-6772.21081204.

Takagi H, Maruyama K, Yoshizawa N, Yamada Y, Sato Y. XRD analysis of carbon stacking structure in coal during heat treatment. Fuel. 2004;83:2427. https://doi.org/10.1016/j.fuel.2004.06.019.

Guo R, Lv C, Xu W, Sun J, Zhu Y, Yang X, Li J, Sun J, Zhang L, Yang D. Effect of intrinsic defects of carbon materials on the sodium storage performance. Adv Energy Mater. 2020;10:1903652. https://doi.org/10.1002/aenm.201903652.

Li D, Sun Q, Zhang Y, Dai X, Ji F, Li K, Yuan Q, Liu X, Ci L. Fast and stable K-ion storage enabled by synergistic interlayer and pore-structure engineering. Nano Res. 2021;14:4502. https://doi.org/10.1007/s12274-021-3324-0.

Zhu YE, Gu H, Chen YN, Yang D, Wei J, Zhou Z. Hard carbon derived from corn straw piths as anode materials for sodium ion batteries. Ionics. 2017;24:1075. https://doi.org/10.1007/s11581-017-2260-1.

Mahmood A, Yuan Z, Sui X, Riaz MA, Yu Z, Liu C, Chen J, Wang C, Zhao S, Mahmood N, Pei Z, Wei L, Chen Y. Foldable and scrollable graphene paper with tuned interlayer spacing as high areal capacity anodes for sodium-ion batteries. Energy Storage Mater. 2021;41:395. https://doi.org/10.1016/j.ensm.2021.06.020.

Li Y, Lu Y, Meng Q, Jensen ACS, Zhang Q, Tong Y, Qi Y, Gu L, Titirici MM, Hu YS. Regulating pore structure of hierarchical porous waste cork-derived hard carbon anode for enhanced Na storage performance. Adv Energy Mater. 2019;9:1902852. https://doi.org/10.1002/aenm.201902852.

Li W, Guo X, Song K, Chen J, Zhang J, Tang G, Liu C, Chen W, Shen C. Binder-induced ultrathin SEI for defect-passivated hard carbon enables highly reversible sodium-ion storage. Adv Energy Mater. 2023;13:2300648. https://doi.org/10.1002/aenm.202300648.

Zheng Y, Lu Y, Qi X, Wang Y, Mu L, Li Y, Ma Q, Li J, Hu YS. Superior electrochemical performance of sodium-ion full-cell using poplar wood derived hard carbon anode. Energy Storage Mater. 2019;18:269. https://doi.org/10.1016/j.ensm.2018.09.002.

Liu M, Wu F, Gong Y, Li Y, Li Y, Feng X, Li Q, Wu C, Bai Y. Interfacial-catalysis-enabled layered and inorganic-rich SEI on hard carbon anodes in ester electrolytes for sodium-ion batteries. Adv Mater. 2023;35:2300002. https://doi.org/10.1002/adma.202300002.

Liang HJ, Gu ZY, Zhao XX, Guo JZ, Yang JL, Li WH, Li B, Liu ZM, Li WL, Wu XL. Ether-based electrolyte chemistry towards high-voltage and long-life Na-ion full batteries. Angew Chem Int Ed. 2021;60:26837. https://doi.org/10.1002/anie.202112550.

Yang J, Zhou X, Wu D, Zhao X, Zhou Z. S-doped N-rich carbon nanosheets with expanded interlayer distance as anode materials for sodium-ion batteries. Adv Mater. 2017;29:1604108. https://doi.org/10.1002/adma.201604108.

Shi WJ, Zhang LY, Yang YL, Alikin DO, Shur VY, Wei XY, Du HL, Jin L. Improved energy storage performance of bismuth sodium titanate-based lead-free relaxor ferroelectric ceramics via Bi-containing complex ions doping. Rare Met. 2022;42(5):1472. https://doi.org/10.1007/s12598-022-02176-x.

Liang HJ, Gu ZY, Zheng XY, Li WH, Zhu LY, Sun ZH, Meng YF, Yu HY, Hou XK, Wu XL. Tempura-like carbon/carbon composite as advanced anode materials for K-ion batteries. J Energy Chem. 2021;59:589. https://doi.org/10.1016/j.jechem.2020.11.039.

Han J, Johnson I, Lu Z, Kudo A, Chen M. Effect of local atomic structure on sodium ion storage in hard amorphous carbon. Nano Lett. 2021;21:6504. https://doi.org/10.1021/acs.nanolett.1c01595.

Yin B, Liang S, Yu D, Cheng B, Egun IL, Lin J, Xie X, Shao H, He H, Pan A. Increasing accessible subsurface to improving rate capability and cycling stability of sodium-ion batteries. Adv Mater. 2021;33:2100808. https://doi.org/10.1002/adma.202100808.

Wang G, Shao M, Ding H, Qi Y, Lian J, Li S, Qiu J, Li H, Huo F. Multiple active sites of carbon for high-rate surface-capacitive sodium-ion storage. Angew Chem Int Ed. 2019;58:13584. https://doi.org/10.1002/anie.201908159.

Du M, Du KD, Guo JZ, Liu Y, Aravindan V, Yang JL, Zhang KY, Gu ZY, Wang XT, Wu XL. Direct reuse of oxide scrap from retired lithium-ion batteries: advanced cathode materials for sodium-ion batteries. Rare Met. 2023;42(5):1603. https://doi.org/10.1007/s12598-022-02230-8.

Gu ZY, Guo JZ, Cao JM, Wang XT, Zhao XX, Zheng XY, Li WH, Sun ZH, Liang HJ, Wu XL. An advanced high-entropy fluorophosphate cathode for sodium-ion batteries with increased working voltage and energy density. Adv Mater. 2022;34:2110108. https://doi.org/10.1002/adma.202110108.

Zou K, Deng W, Cai P, Deng X, Wang B, Liu C, Li J, Hou H, Zou G, Ji X. Prelithiation/presodiation techniques for advanced electrochemical energy storage systems: concepts. Appl, Perspect, Adv Funct Mater. 2021;31:2005581. https://doi.org/10.1002/adfm.202005581.

Chen X, Tian J, Li P, Fang Y, Fang Y, Liang X, Feng J, Dong J, Ai X, Yang H, Cao Y. An overall understanding of sodium storage behaviors in hard carbons by an “adsorption-intercalation/filling” hybrid mechanism. Adv Energy Mater. 2022;12:2200886. https://doi.org/10.1002/aenm.202200886.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 52173246), 111 project (No. B13013) and Shccig-Qinling Program (No. SMYJY20220574).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, MY., Zhang, KY., Ang, E.H. et al. Structural regulation of coal-derived hard carbon anode for sodium-ion batteries via pre-oxidation. Rare Met. 43, 2585–2596 (2024). https://doi.org/10.1007/s12598-023-02607-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02607-3