Abstract

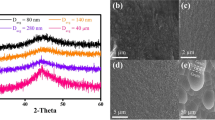

A study of the phase transformation process of a Fe-Ni-B-Si-P-Nb metallic glass using a suite of advanced characterization tools is reported. Transmission electron microscopy (TEM) and small angle neutron scattering (SANS) experiments show that the as-spun metallic glass ribbon has a dual-phase structure with bcc nanoclusters of a size of 2–3 nm. In situ high-energy X-ray diffraction (XRD) reveals a three-stage crystallization process when heating the metallic glass into supercooled liquid states. The isothermal annealing experiment shows the nanoclusters grow instantly without incubation. The easy formation and phase stability of the nanoclusters are due to the low interfacial energy between the amorphous matrix and clusters, as real space analysis shows that the nanoclusters and the amorphous matrix share similar short-to-medium-range orders. We further find that the dual-phase structure reduces local magneto-anisotropy and enhances effective magnetic permeability, resulting in an excellent stress-impedance effect without sacrificing coercivity. Our work sheds light on the structure-property engineering of soft magnetic metallic glasses and provides a foundation for developing novel magnetic functional materials with nanostructured dual-phases.

Graphical Abstract

摘要

通过一系列先进的表征手段对 Fe-Ni-B-Si-P-Nb金属玻璃的相变行为进行了研究。透射电子显微镜(TEM)和小角中子散射实验表明, 该铸态金属玻璃带材具有双相结构, 其中包含尺寸为2–3nm的体心立方结构纳米团簇。原位高能X射线衍射(XRD)实验揭示了在加热至过冷液相区时该体系的结晶过程分为三个阶段。等温退火实验表明, 纳米团簇的形核长大不具备孵化期。实空间分析表明, 纳米团簇和非晶态基体具有相似的短程序和中程序结构, 预示着纳米团簇的易于形成和相对稳定性可能归因于非晶态基体和团簇之间较低的界面能。我们进一步发现, 双相结构降低了局部磁各向异性并提高了有效磁导率, 从而实现大幅提高应力阻抗效应而不牺牲矫顽力。本研究推动了软磁金属玻璃的结构-性能调控工程的发展, 并为开发具有双相纳米结构的新型磁性功能材料提供了参考。

Similar content being viewed by others

References

McHenry ME, Willard MA, Laughlin DE. Amorphous and nanocrystalline materials for applications as soft magnets. Prog Mater Sci. 1999;44(4):291. https://doi.org/10.1016/S0079-6425(99)00002-X.

Shen B, Inoue A, Chang C. Superhigh strength and good soft-magnetic properties of (Fe, Co)-B-Si-Nb bulk glassy alloys with high glass-forming ability. Appl Phys Lett. 2004;85(21):4911. https://doi.org/10.1063/1.1827349.

Inoue A, Shen B, Koshiba H, Kato H, Yavari AR. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nat Mater. 2003;2(10):661. https://doi.org/10.1038/nmat982.

Herzer G. Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater. 2013;61(3):718. https://doi.org/10.1016/j.actamat.2012.10.040.

Zhao X, Lan S, Hu L, Wu Z, Dong Y, Ren Y, Wang XL. Features of relaxation modes in soft magnetic metallic glasses and their correlation with magnetic ordering. J Non-Cryst Solids. 2023;602:122087. https://doi.org/10.1016/j.jnoncrysol.2022.122087.

Zhang SY, Gao YY, Zhang ZB, Gu T, Liang XB, Wang LZ. Research progress on functional properties of novel high-entropy metallic-glasses. Chin J Rare Met. 2021;45(6):717. https://doi.org/10.13373/j.cnki.cjrm.XY20080032.

Ram BS, Paul A, Kulkarni S. Soft magnetic materials and their applications in transformers. J Magn Magn Mater. 2021;537:168210. https://doi.org/10.1016/j.jmmm.2021.168210.

Zhang X, Dong Y, He A, Xie L, Li F, Chang L, Xiao H, Li H, Wang T. Improvement of SMPs in Fe-Si-BPC-Cu-Nb alloys via harmonizing P and B. J Magn Magn Mater. 2020;506:166757. https://doi.org/10.1016/j.jmmm.2020.166757.

Phan TA, Hara M, Oguchi H, Kuwano H. Current sensors using Fe-B-Nd-Nb magnetic metallic glass micro-cantilevers. Microelectron Eng. 2015;135:28. https://doi.org/10.1016/j.mee.2015.02.043.

Shen LP, Mohri K, Uchiyama T, Honkura Y. Sensitive acceleration sensor using amorphous wire SI element combined with CMOS IC multivibrator for environmental sensing. IEEE Trans Magn. 2000;36(5):3667. https://doi.org/10.1109/20.908935.

Cobeño AF, Zhukov A, Blanco JM, Larin V, Gonzalez J. Magnetoelastic sensor based on GMI of amorphous microwire. Sens Actuators A. 2001;91(1):95. https://doi.org/10.1016/S0924-4247(01)00502-7.

Bayri N, Atalay S. Giant stress-impedance effect in Fe71Cr7Si9B13 amorphous wires. J Alloy Compd. 2004;381(1–2):245. https://doi.org/10.1016/j.jallcom.2004.03.077.

Suryanarayana C, Inoue A. Iron-based bulk metallic glasses. Int Mater Rev. 2013;58(3):131. https://doi.org/10.1179/1743280412Y.0000000007.

Huang B, Yang Y, Wang AD, Wang Q, Liu CT. Saturated magnetization and glass forming ability of soft magnetic Fe-based metallic glasses. Intermetallics. 2017;84:74. https://doi.org/10.1016/j.intermet.2017.01.003.

Zhou XC, Chen SQ, Zhou MJ, Li M, Lan S, Feng T. Highly efficient cobalt-based amorphous catalyst for peroxymonosulfate activation toward wastewater remediation. Rare Met. 2023;42(4):1160. https://doi.org/10.1007/s12598-022-02220-w.

Zhang T, Liu F, Pang S, Li R. Ductile Fe-based bulk metallic glass with good soft-magnetic properties. Mater Trans. 2007;48(5):1157. https://doi.org/10.2320/matertrans.48.1157.

Corte-Leon P, Zhukova V, Ipatov M, Blanco J, Gonzalez J, Churyukanova M, Baraibar J, Taskaev S, Zhukov A. Stress dependence of the magnetic properties of glass-coated amorphous microwires. J Alloy Compd. 2019;789:201. https://doi.org/10.1016/j.jallcom.2019.03.044.

Herrero-Gómez C, Samwer K. Mechanical avalanches promoted by magnetoelastic coupling in magnetic metallic glasses. J Phys Condens Matter. 2018;30(46):465803. https://doi.org/10.1088/1361-648X/aae3bc.

Shokrollahi H, Janghorban K. Soft magnetic composite materials (SMCs). J Mater Process Technol. 2007;189(1–3):1. https://doi.org/10.1016/j.jmatprotec.2007.02.034.

Pacheco V, Karlsson D, Marattukalam JJ, Stolpe M, Hjörvarsson B, Jansson U, Sahlberg M. Thermal stability and crystallization of a Zr-based metallic glass produced by suction casting and selective laser melting. J Alloys Compd. 2020;825:153995. https://doi.org/10.1016/j.jallcom.2020.153995.

Li Z, Parsons R, Kishimoto H, Shoji T, Kato A, Karel J, Suzuki K. Nanocrystalline (Fe, Co, Ni)86B14 soft magnetic alloys prepared by ultra-rapid annealing. J Alloys Compd. 2022;902:162544. https://doi.org/10.1016/j.jallcom.2021.162544.

Jiang L, Zhang Y, Tong X, Suzuki T, Makino A. Unique influence of heating rate on the magnetic softness of Fe81.5Si0.5B4.5P11Cu0.5C2 nanocrystalline alloy. J Magn Magn Mater. 2019;471:148. https://doi.org/10.1016/j.jmmm.2018.09.075.

Gazda P, Nowicki M, Szewczyk R. Comparison of stress-impedance effect in amorphous ribbons with positive and negative magnetostriction. Materials (Basel). 2019;12(2):275. https://doi.org/10.3390/ma12020275.

Szewczyk R, Bienkowski A, Kolano R. Influence of nanocrystalization on magnetoelastic Villari effect in Fe73.5Nb3Cu1Si13.5B9 alloy. Cryst Res Technol. 2003;38(35):320. https://doi.org/10.1002/crat.200310038.

Shuai S, Lu S, Xiang Z, Lu W. Stress-induced giant magneto-impedance effect of amorphous CoFeNiSiPB ribbon with magnetic field annealing. J Magn Magn Mater. 2022;551:169131. https://doi.org/10.1016/j.jmmm.2022.169131.

Murali P, Ramamurty U. Embrittlement of a bulk metallic glass due to sub-Tg annealing. Acta Mater. 2005;53(5):1467. https://doi.org/10.1016/j.actamat.2004.11.040.

Ramamurty U, Lee M, Basu J, Li Y. Embrittlement of a bulk metallic glass due to low-temperature annealing. Scripta Mater. 2002;47(2):107. https://doi.org/10.1016/S1359-6462(02)00102-1.

Ketov SV, Sun YH, Nachum S, Lu Z, Checchi A, Beraldin AR, Bai HY, Wang WH, Louzguine-Luzgin DV, Carpenter MA, Greer AL. Rejuvenation of metallic glasses by non-affine thermal strain. Nature. 2015;524(7564):200. https://doi.org/10.1038/nature14674.

Li H, Lu Z, Wang S, Wu Y, Lu Z. Fe-based bulk metallic glasses: glass formation, fabrication, properties and applications. Prog Mater Sci. 2019;103:235. https://doi.org/10.1016/j.pmatsci.2019.01.003.

Li Q, Li J, Gong P, Yao K, Gao J, Li H. Formation of bulk magnetic ternary Fe80P13C7 glassy alloy. Intermetallics. 2012;26:62. https://doi.org/10.1016/j.intermet.2012.03.045.

Herzer G. Anisotropies in soft magnetic nanocrystalline alloys. J Magn Magn Mater. 2005;294(2):99. https://doi.org/10.1016/j.jmmm.2005.03.020.

Li H, Wang A, Liu T, Chen P, He A, Li Q, Luan J, Liu CT. Design of Fe-based nanocrystalline alloys with superior magnetization and manufacturability. Mater Today. 2021;42:49. https://doi.org/10.1016/j.mattod.2020.09.030.

Yoshizawa YA, Oguma S, Yamauchi K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys. 1988;64(10):6044. https://doi.org/10.1063/1.342149.

Makino A, Men H, Kubota T, Yubuta K, Inoue A. FeSiBPCu nanocrystalline soft magnetic alloys with high Bs of 1.9 Tesla produced by crystallizing hetero-amorphous phase. Materials Trans. 2009;50(1):204. https://doi.org/10.2320/matertrans.MER2008306.

Zhou J, Yang W, Yuan C, Sun B, Shen B. Ductile FeNi-based bulk metallic glasses with high strength and excellent soft magnetic properties. J Alloy Compd. 2018;742:318. https://doi.org/10.1016/j.jallcom.2018.01.317.

Zhou J, Wang Q, Hui X, Zeng Q, Xiong Y, Yin K, Sun B, Sun L, Stoica M, Wang W. A novel FeNi-based bulk metallic glass with high notch toughness over 70 MPa·m1/2 combined with excellent soft magnetic properties. Mater Des. 2020;191:108597. https://doi.org/10.1016/j.matdes.2020.108597.

Liu Y, Yi Y, Shao W, Shao Y. Microstructure and magnetic properties of soft magnetic powder cores of amorphous and nanocrystalline alloys. J Magn Magn Mater. 2013;330:119. https://doi.org/10.1016/j.jmmm.2012.10.043.

Lan S, Ren Y, Wei XY, Wang B, Gilbert EP, Shibayama T, Watanabe S, Ohnuma M, Wang XL. Hidden amorphous phase and reentrant supercooled liquid in Pd-Ni-P metallic glasses. Nat Commun. 2017;8(1):14679. https://doi.org/10.1038/ncomms14679.

Qiu X, Thompson JW, Billinge SJ. PDFgetX2: a GUI-driven program to obtain the pair distribution function from X-ray powder diffraction data. J Appl Crystallogr. 2004;37(4):678. https://doi.org/10.1107/S0021889804011744.

Ke Y, He C, Zheng H, Geng Y, Fu J, Zhang S, Hu H, Wang S, Zhou B, Wang F. The time-of-flight small-angle neutron spectrometer at China spallation neutron source. Neutron News. 2018;29(2):14. https://doi.org/10.1080/10448632.2018.1514197.

Wang A, Zhang M, Zhang J, Men H, Shen B, Pang S, Zhang T. FeNiPBNb bulk glassy alloys with good soft-magnetic properties. J Alloy Compd. 2012;536:S354. https://doi.org/10.1016/j.jallcom.2011.12.028.

Li KH, Ge JC, Liu SN, Fu S, Yin ZX, Zhang WT, Chen GX, Wei SC, Ji H, Feng T. In situ scattering study of multiscale structural evolution during liquid-liquid phase transition in Mg-based metallic glasses. Rare Met. 2021;40(11):3107. https://doi.org/10.1007/s12598-021-01767-4.

Corte-León P, Zhukova V, Ipatov M, Blanco JM, Zhukov A. Effect of Joule heating on giant magnetoimpedance effect and magnetic properties of Co-rich microwires. J Alloys Compd. 2021;883:160778. https://doi.org/10.1016/j.jallcom.2021.160778.

Chen Z, Li DR, Lu ZC, Zhou SX. Giant Stress-impedance effect in Co71.8Fe4.9Nb0.8Si7.5B1.5 glass-covered amorphous wires. J Iron Steel Res Int. 2006;13(4):49. https://doi.org/10.1016/S1006-706X(06)60077-0.

Zhukov A, Ipatov M, Talaat A, Churyukanova M, Kaloshkin S, Zhukova V. Giant magnetoimpedance in thin amorphous and nanocrystalline microwires. Appl Phys A. 2013;115(2):547. https://doi.org/10.1007/s00339-013-8028-1.

Peng B, Zhang WL, Zhang WX, Jiang HC, Yang SQ. Simulation of stress impedance effect in magnetoelastic films. J Magn Magn Mater. 2005;288:326. https://doi.org/10.1016/j.jmmm.2004.09.114.

Ying HQ, Liu SN, Wu ZD, Dong WX, Ge JC, Hahn H, Provenzano V, Wang XL, Lan S. Phase selection rule of high-entropy metallic glasses with different short-to-medium-range orders. Rare Met. 2022;41(6):2021. https://doi.org/10.1007/s12598-022-01973-8.

Kim DH, Park JM, Kim DH, Kim WT. Development of quaternary Fe-B-Y-Nb bulk glassy alloys with high glass-forming ability. J Mater Res. 2007;22(2):471. https://doi.org/10.1557/jmr.2007.0057.

Wu Y, Xiao Y, Chen G, Liu CT, Lu Z. Bulk metallic glass composites with transformation-mediated work-hardening and ductility. Adv Mater. 2010;22(25):2770.

Wang JJ, Kou ZD, Fu S, Wu SS, Liu SN, Yan MY, Wang D, Lan S, Hahn H, Feng T. Microstructure and magnetic properties evolution of Al/CoCrFeNi nanocrystalline high-entropy alloy composite. Rare Met. 2022;41(6):2038. https://doi.org/10.1007/s12598-021-01931-w.

Heinemann A, Hermann H, Wiedenmann A, Mattern N, Wetzig K. A small-angle neutron scattering model for polydisperse spherical particles with diffusion zones and application to soft magnetic metallic glass. J Appl Crystallogr. 2000;33(6):1386. https://doi.org/10.1107/S0021889800013248.

Luo Q, Chen H, Chen W, Wang C, Xu W, Li Q. Thermodynamic prediction of martensitic transformation temperature in Fe-Ni-C system. Scripta Mater. 2020;187:413. https://doi.org/10.1016/j.scriptamat.2020.06.062.

Lan S, Wu Z, Wei X, Zhou J, Lu Z, Neuefeind J, Wang XL. Structure origin of a transition of classic-to-avalanche nucleation in Zr-Cu-Al bulk metallic glasses. Acta Mater. 2018;149:108. https://doi.org/10.1016/j.actamat.2018.02.028.

Turnbull D. Under what conditions can a glass be formed? Contemp Phys. 1969;10(5):473. https://doi.org/10.1080/00107516908204405.

Lan S, Zhu L, Wu Z, Gu L, Zhang Q, Kong H, Liu J, Song R, Liu S, Sha G. A medium-range structure motif linking amorphous and crystalline states. Nat Mater. 2021;20(10):1347. https://doi.org/10.1038/s41563-021-01011-5.

Ding J, Ma E, Asta M, Ritchie RO. Second-nearest-neighbor correlations from connection of atomic packing motifs in metallic glasses and liquids. Sci Rep. 2015;5:17429. https://doi.org/10.1038/srep17429.

Sarac B, Ivanov YP, Chuvilin A, Schöberl T, Stoica M, Zhang Z, Eckert J. Origin of large plasticity and multiscale effects in iron-based metallic glasses. Nat Commun. 2018;9(1):1. https://doi.org/10.1038/s41467-018-03744-5.

Wu G, Chan KC, Zhu L, Sun L, Lu J. Dual-phase nanostructuring as a route to high-strength magnesium alloys. Nature. 2017;545(7652):80. https://doi.org/10.1038/nature21691.

Hao Z, Qin K, Song K, Cao C. Effect of Fe addition on glass-forming ability, thermal stability of B2 CuZr phase and crystallization kinetics for CuZr-based amorphous alloys. J Market Res. 2021;15:6464. https://doi.org/10.1016/j.jmrt.2021.11.093.

Song K, Pauly S, Zhang Y, Li R, Gorantla S, Narayanan N, Kühn U, Gemming T, Eckert J. Triple yielding and deformation mechanisms in metastable Cu4.75Zr4.75Al5 composites. Acta Mater. 2012;60(17):6000. https://doi.org/10.1016/j.actamat.2012.07.015.

Fischer FD, Reisner G, Werner E, Tanaka K, Cailletaud G, Antretter T. A new view on transformation induced plasticity (TRIP). Int J Plast. 2000;16(7–8):723. https://doi.org/10.1016/S0749-6419(99)00078-9.

Ouyang S, Song LJ, Liu YH, Huo JT, Wang JQ, Xu W, Li JL, Wang CT, Wang XM, Li RW. Correlation between the viscoelastic heterogeneity and the domain wall motion of Fe-based metallic glass. Phys Rev Mater. 2018;2(6):063601. https://doi.org/10.1103/PhysRevMaterials.2.063601.

Li Y, Shen N, Zhang S, Wu Y, Chen L, Lv K, He Z, Li F, Hui X. Crystallization behavior and soft magnetic properties of Fe-B-P-C-Cu ribbons with amorphous/α-Fe hierarchic structure. Intermetallics. 2021;131:107100. https://doi.org/10.1016/j.intermet.2021.107100.

Acknowledgements

This study was financially supported by the National Key R&D Program of China (No. 2021YFB3802800), the National Natural Science Foundation of China (Nos. 52222104, 12261160364, 51871120, 52201190 and 51520105001) and the Natural Science Foundation of Jiangsu Province (No. BK20200019). S. Lan acknowledges the support by Shenzhen Science and Technology Innovation Commission (No. JCYJ202000109105618137). Z.-D. Wu and S. Lan acknowledge the support by Guangdong-Hong Kong-Macao Joint Laboratory for Neutron Scattering Science and Technology. X.-L. Wang acknowledges the support of Shenzhen Science and Technology Innovation Committee (No. JCYJ20170413140446951) and partial support by the Research Grants Council of the Hong Kong Special Administrative Region (No. CityU173/22). Y.B. Ke acknowledges the support of the Youth Innovation Promotion Association, CAS (No. 2020010). This research used the resources of the Advanced Photon Source, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory (No. DE-AC02-06CH11357).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

Si Lan is an editorial board member for Rare Metals and was not involved in the editorial review or the decision to publish this article. The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ge, JC., Liu, AH., Wu, ZD. et al. Phase transformation behavior of a dual-phase nanostructured Fe-Ni-B-Si-P-Nb metallic glass and its correlation with stress-impedance properties. Rare Met. 42, 2757–2766 (2023). https://doi.org/10.1007/s12598-023-02345-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02345-6