Abstract

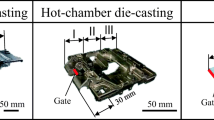

A new high-pressure die-cast (HPDC) Mg–4Al–3La–1Ca–0.3Mn (ALaX431) alloy with high strength has successfully been fabricated. This HPDC alloy in peak-aged state exhibits tensile yield strength (TYS) of 220 MPa at room temperature and TYS of 145 MPa at 250 °C, higher than the corresponding strength of HPDC Mg alloys reported so far. These high strengths are mainly due to the formation of fine grained structure, semi-continuous reticular structure consisting of stable Al3La and (Mg,Al)2Ca particles along grain boundaries and numerous nanoscale Al2Ca precipitates within grains. Due to its higher strength than existing HPDC Mg alloys, the new developed alloy has great application potential.

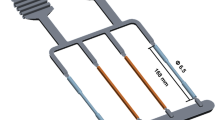

Graphic Abstract

Similar content being viewed by others

References

Pekguleryuz MO, Kaya AA. Creep resistant magnesium alloys for powertrain applications. Adv Eng Mater. 2003;5(12):866.

Pekguleryuz M, Celikin M. Creep resistance in magnesium alloys. Int Mater Rev. 2010;55(4):197.

Yang Q, Lv SH, Qin PF, Qiu X, Hua XR, Guan K, Sun W, Liu XJ, Meng J. Interphase boundary segregation induced phase transformation in a high-pressure die casting Mg–Al–La–Ca–Mn alloy. Mater Des. 2020;190:108566.

Bakke P, Bowles AL, Westengen H. Elevated temperature alloys—paths for further performance gains in AE44. In: Kainer KU, editors. Magnesium: Proceedings of the 7th International Conference Magnesium Alloys and their Applications. Weinheim: WILEY-VCH Verlag GmbH, 2007. 55.

Lv S, Lü X, Meng F, Yang Q, Qiu X, Qin P, Duan Q, Meng J. Microstructures and mechanical properties in a Gd-modified high-pressure die casting Mg–4Al–3La–0.3Mn alloy. Mater Sci Eng A. 2020;773:138725.

Xu SW, Matsumoto N, Yamamoto K, Kamado S, Honma T, Kojima Y. High temperature tensile properties of as-cast Mg–Al–Ca alloys. Mater Sci Eng A. 2009;509(1–2):105.

Suzuki A, Saddock ND, Terbush JR, Powell BR, Jones JW, Pollock TM. Precipitation strengthening of a Mg–Al–Ca-based AXJ530 die-cast alloy. Metall Mater Trans A. 2008;39(3):696.

Nami B, Razavi H, Miresmaeili SM, Mirdamadi S, Shabestari SG. Impression creep properties of a semi-solid processed magnesium–aluminum alloy containing calcium and rare earth elements. Scr Mater. 2011;65(3):221.

Nami B, Razavi H, Mirdamadi S, Shabestari SG, Miresmaeili SM. Effect of Ca and rare earth elements on impression creep properties of AZ91 magnesium alloy. Metall Mater Trans A. 2010;41(8):1973.

Wang QD, Peng JG, Michel S, Blandin JJ. Effects of aging on the microstructures and mechanical properties of extruded AM50 + xCa magnesium alloys. Rare Met. 2006;25(4):377.

Yang Q, Guan K, Bu FQ, Zhang YQ, Qiu X, Tian Z, Liu XJ, Meng J. Microstructures and tensile properties of a high-strength die-cast Mg–4Al–2RE–2Ca–0.3Mn alloy. Mater Charact. 2016;113:180.

Zhang Y, Yang L, Dai J, Guo G, Liu Z. Effect of Ca and Sr on microstructure and compressive creep property of Mg–4Al–RE alloys. Mater Sci Eng A. 2014;610:309.

Zhang JH, Zhang ML, Meng J, Wu RZ, Tang DX. Microstructures and mechanical properties of heat-resistant high-pressure die-cast Mg–4Al–xLa–0.3Mn (x = 1, 2, 4, 6) alloys. Mater Sci Eng A. 2010;527(10–11):2527.

Zhang JH, Leng Z, Zhang ML, Meng J, Wu RZ. Effect of Ce on microstructure, mechanical properties and corrosion behavior of high-pressure die-cast Mg–4Al-based alloy. J Alloys Compd. 2011;509(3):1069.

Wu HR, Du WB, Li SB, Liu K, Wang ZH. Microstructure and mechanical properties of AZ31 magnesium alloy reinforced by I-phase. Rare Met. 2019;38(8):733.

Su ML, Zhang JH, Feng Y, Bai YJ, Wang W, Zhang ZW, Jiang FC. Al–Nd intermetallic phase stability and its effects on mechanical properties and corrosion resistance of HPDC Mg–4Al–4Nd–0.2Mn alloy. J Alloys Compd. 2017;691:634.

Tian Z, Yang Q, Guan K, Cao ZY, Meng J. Microstructural evolution and aging behavior of Mg–4.5Y–2.5Nd–1.0Gd–0.5Zr alloys with different Zn additions. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01510-5.

Zhang Z, Zhang JH, Wang J, Li ZH, Xie JS, Liu SJ, Guan K, Wu RZ. Toward the development of Mg alloys with simultaneously improved strength and ductility by refining grain size via the deformation process. Int J Miner Metall Mater. 2020. https://doi.org/10.1007/s12613-020-2190-1.

Qin PF, Yang Q, Guan K, Meng FZ, Lv SH, Li BS, Zhang DD, Wang N, Zhang JH, Meng J. Microstructures and mechanical properties of a high pressure die-cast Mg–4Al–4Gd–0.3Mn alloy. Mater Sci Eng A. 2019;764:138254.

Guan K, Meng FZ, Qin PF, Yang Q, Zhang DD, Li BS, Sun W, Lv SH, Huang YD, Hort N, Meng J. Effects of samarium content on microstructure and mechanical properties of Mg–0.5Zn–0.5Zr alloy. J Mater Sci Technol. 2019;35(7):1368.

Anyanwu IA, Gokan Y, Suzuki A, Kamado S, Kojima Y, Takeda S, Ishida T. Effect of substituting cerium-rich mischmetal with lanthanum on high temperature properties of die-cast Mg–Zn–Al–Ca–RE alloys. Mater Sci Eng A. 2004;380(1–2):93.

Zhu SM, Easton MA, Abbott TB, Gibson MA, Nie JF. The influence of individual rare earth elements (La, Ce, or Nd) on creep resistance of die-cast magnesium alloy AE44. Adv Eng Mater. 2012;18(6):932.

Zhang J, Yu P, Liu K, Fang D, Tang D, Meng J. Effect of substituting cerium-rich mischmetal with lanthanum on microstructure and mechanical properties of die-cast Mg–Al–RE alloys. Mater Des. 2009;30(7):2372.

Luo AA, Balogh MP, Powell BR. Creep and microstructure of magnesium–aluminum–calcium based alloys. Metall Mater Trans A. 2002;33(3):567.

Meng FZ, Lv SH, Yang Q, Qin PF, Zhang JH, Guan K, Huang YD, Hort N, Li BS, Liu XJ, Meng J. Developing a die casting magnesium alloy with excellent mechanical performance by controlling intermetallic phase. J Alloys Compd. 2019;795:436.

Suzuki A, Saddock ND, Jones JW, Pollock TM. Structure and transition of eutectic (Mg, Al)2Ca Laves phase in a die-cast Mg–Al–Ca base alloy. Scr Mater. 2004;51(10):1005.

Zhu SM, Mordike BL, Nie JF. Creep and rupture properties of a squeeze-cast Mg–Al–Ca alloy. Metall Mater Trans A. 2006;37(4):1221.

Liu XQ, Qiao XG, Li Z, Zheng MY. High strength and excellent ductility of dilute Mg–0.68Al–0.32Ca–0.50Mn (wt%) extrusion alloy obtained by T6 treatment. Mater Charact. 2020;162:110197.

Zhang JH, Liu SJ, Leng Z, Zhang ML, Meng J, Wu RZ. Microstructures and mechanical properties of heat-resistant HPDC Mg–4Al-based alloys containing cheap mischmetal. Mater Sci Eng A. 2011;528(6):2670.

Luo AA. Recent magnesium alloy development for elevated temperature applications. Int Mater Rev. 2004;49(1):13.

Pekguleryuz MO. Magnesium diecasting alloys for high temperature applications. In: Luo AA, editors. Magnesium Technology 2004. TMS 2004. 281.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51701200 and 11804030), the Fundamental Research Funds for the Central Universities (No. 3072020CF1009), the Open Funds of the State Key Laboratory of Rare Earth Resource Utilization (Nos. RERU2020008 and 2020012), the Scientific and Technological Developing Scheme of Jilin Province (No. 20200801048GH) and the Jilin Scientific and Technological Development Programs (No. 20200201240JC).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Qin, PF., Yang, Q., He, YY. et al. Microstructure and mechanical properties of high-strength high-pressure die-cast Mg–4Al–3La–1Ca–0.3Mn alloy. Rare Met. 40, 2956–2963 (2021). https://doi.org/10.1007/s12598-020-01661-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01661-5