Abstract

Hot-rolled high-Mg-alloyed Al–Mg alloy (Al–9.2Mg–0.8Mn–0.2Zr–0.15Ti, labeled as 5A12) plates were successfully friction stir welded at rotating rates ranging from 750 to 1500 r·min−1 at a constant welding speed of 50 mm·min−1. The joints were characterized by optical microscopy (OM), electron backscatter diffraction (EBSD), transmission electron microscopy (TEM), scanning electron microscopy (SEM), electron-dispersive spectroscopy (EDS), and tensile testing. All the joints are volume defect-free and exhibit fine, equiaxed dynamic recrystallization (DRX) grains with high-angle grain boundaries (HAGBs) fractions of 88.6%–93.3% in the nugget zones (NZs). The DRX grain size and the second-phase particle size in the NZs have a parabolic relation with the rotating rate. Furthermore, among the joints tested, the joint prepared at 1000 r·min−1, which has the highest ultimate tensile strength ((478 ± 3) MPa) and the largest elongation to rupture (22.5% ± 1.4%)—approximately 87.5% and 145.2% those of the base metal, respectively, exhibits the smallest grain size of 2.93 μm, as well as the smallest particle size in the NZs. These excellent mechanical properties can be ascribed to the combined effects of the fine DRX grains with high fraction of HAGBs and the fine second-phase particles with a uniform distribution.

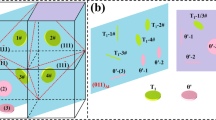

Graphic abstract

Similar content being viewed by others

References

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, Miller WS. Recent development in aluminium alloys for aerospace applications. Mater Sci Eng A. 2000;280(1):102.

Zhao H, Debroy T. Weld metal composition change during conduction mode laser welding of aluminum alloy 5182. Metall Mater Trans B. 2001;32(1):163.

Pastor M, Zhao H, Martukanitz RP. Porosity, underfill and magnesium lose during continuous wave Nd: YAG laser welding of thin plates of aluminum alloys 5182 and 5754. Weld J. 1999;78(6):207.

Punkari A, Weckman DC, Kerr HW. Effects of magnesium content on dual beam Nd: YAG laser welding of Al–Mg alloys. Sci Technol Weld Join. 2003;8(4):269.

Çam G, Koçak M. Progress in joining of advanced materials. Metall R. 1998;43(1):1.

Wang G, Zhao Y, Hao Y. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing. J Mater Sci Technol. 2018;34(1):73.

Mishra RS, Ma ZY. Friction stir welding and processing. Mater Sci Eng R. 2005;50:1.

Wang BB, Chen FF, Liu F, Wang WG, Xue P, Ma ZY. Enhanced mechanical properties of friction stir welded 5083Al-H19 joints with additional water cooling. J Mater Sci Technol. 2017;33(9):1009.

Jamalian HM, Farahani M, Givi MKB, Vafaei MA. Study on the effects of friction stir welding process parameters on the microstructure and mechanical properties of 5086-H34 aluminum welded joints. Int J Adv Manuf Technol. 2016;83(1–4):611.

Moshwan R, Yusof F, Hassan MA, Rahmat SM. Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded Al–Mg–Cr–Mn (AA5052-O) alloy. Mater Des. 2015;66:118.

Chen SJ, Li XX, Jiang XQ, Yuan T, Hu YZ. The effect of microstructure on the mechanical properties of friction stir welded 5A06 Al Alloy. Mater Sci Eng A. 2018;735:382.

Park JC, Kim SJ. Optimization of friction stir welding with the various welding parameters for Al–Mg alloys. Rare Met. 2011;30(1S):628.

El Rayes MM, Soliman MS, Abbas AT, Pimenov DY, Erdakov IN, Abdel-mawla MM. Effect of feed rate in FSW on the mechanical and microstructural properties of AA5754 joints. Adv Mater Sci Eng. 2019. https://doi.org/10.1155/2019/4156176.

Chen Y, Ding H, Li JZ, Cai ZH, Zhao JW, Yang WJ. Influence of multi-pass friction stir processing on the microstructure and mechanical properties of Al-5083 alloy. Mater Sci Eng A. 2015;650(5):1157.

Hao HL, Ni DR, Huang H, Wang D, Xiao BL, Nie ZR, Ma ZY. Effect of welding parameters on microstructure and mechanical properties of friction stir welded Al–Mg–Er alloy. Mater Sci Eng A. 2013;559:889.

Mohammadi-pour M, Khodabandeh A, Mohammadi-pour S, Paidar M. Microstructure and mechanical properties of joints welded by friction-stir welding in aluminum alloy 7075-T6 plates for aerospace application. Rare Met. 2016. https://doi.org/10.1007/s12598-016-0692-9.

Xue P, Xie GM, Xiao BL, Ma ZY, Geng L. Effect of heat input conditions on microstructure and mechanical properties of friction-stir-welded pure copper. Metall Mater Trans A. 2010;41(8):2010.

Cho CH, Son HW, Lee JC, Son KT, Lee JW, Hyun SK. Effects of high Mg content and processing parameters on Portevin-Le Chatelier and negative strain rate sensitivity effects in Al–Mg alloys. Mater Sci Eng A. 2020. https://doi.org/10.1016/j.msea.2020.139151.

Etter AL, Baudin T, Fredj N, Penelle R. Recrystallization mechanisms in 5251 H14 and 5251 O aluminum friction stir welds. Mater Sci Eng A. 2007;445:94.

Morishige T, Hirata T, Uesugi T, Takigawa Y, Tsujikawa M, Higashi K. Effect of Mg content on the minimum grain size of Al–Mg alloys obtained by friction stir processing. Scr Mater. 2011;64(4):355.

Iwahashi Y, Horita Z, Nemoto M, Langdon TG. Factors influencing the equilibrium grain size in equal-channel angular pressing: role of Mg additions to aluminum. Metall Mater Trans A. 1998;29(10):2503.

Ma ZY, Feng AH, Chen DL, Shen J. Recent advances in friction stir welding/processing of aluminum alloys: microstructural evolution and mechanical properties. Crit Rev Solid State Mater Sci. 2018;43(4):269.

Humphreys FJ, Hatherly M. Recrystallization and Related Annealing Phenomena. 2nd ed. Amsterdam: Elsevier; 2004. 285.

Suhuddin UFHR, Mironov S, Sato YS, Kokawa H. Grain structure and texture evolution during friction stir welding of thin 6016 aluminum alloy sheets. Mater Sci Eng A. 2010;527(7–8):1962.

Su JQ, Nelson TW, Mishra R, Mahoney M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003;51(3):713.

Huang K, Logé RE. A review of dynamic recrystallization phenomena in metallic materials. Mater Des. 2016;111:548.

Yamashita A, Yamaguchi D, Horita Z, Langdon TG. Influence of pressing temperature on microstructural development in equal-channel angular pressing. Mater Sci Eng A. 2000;287(1):100.

Valiev RZ, Langdon TG. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci. 2006;51(7):881.

Kapoor R, Kumar R, Mishra RS, Huskamp CS, Sankaran KK. Influence of fraction of high angle boundaries on the mechanical behavior of an ultrafine grained Al–Mg alloy. Mater Sci Eng A. 2010;527(20):5246.

Zha M, Li Y, Mathiesen RH, Bjørge R, Roven HJ. Microstructure evolution and mechanical behavior of a binary Al–7Mg alloy processed by equal-channel angular pressing. Acta Mater. 2015;84:42.

Wang J, Iwahashi Y, Horita Z, Furukawa M, Nemoto M, Valiev RZ, Langdon TG. An investigation of microstructural stability in an Al–Mg alloy with submicrometer grain size. Acta Mater. 1996;44(7):2973.

Kulitskiy V, Malopheyev S, Mironov S, Kaibyshev R. Grain refinement in an Al–Mg–Sc alloy: equal channel angular pressing versus friction-stir processing. Mater Sci Eng A. 2016;674(30):480.

Inagaki K, Mironov S, Sato YS, Fujii HT, Kokawa H. Effect of peak temperature during friction stir welding on microstructure evolution of aluminum alloy 1050. Proc Int Joint Symp Join Weld. 2013. https://doi.org/10.1533/978-1-78242-164-1.41.

Hassan KAA, Prangnell PB, Norman AF, Price DA, Williams SW. Effect of welding parameters on nugget zone microstructure and properties in high strength aluminum alloy friction stir welds. Sci Technol Weld Join. 2013;8(4):257.

Malopheyev S, Mironov S, Kulitskiy V, Kaibyshev R. Friction-stir welding of ultra-fine grained sheets of Al–Mg–Sc–Zr alloy. Mater Sci Eng A. 2015;624:132.

Besel M, Besel Y, Mercado UA, Kakiuchi T, Uematsu Y. Fatigue behavior of friction stir welded Al–Mg–Sc alloy. Int J Fatigue. 2015;77:1.

Chowdhury SH, Chen DL, Bhole SD, Cao X, Wanjara P. Friction stir welded AZ31 magnesium alloy: microstructure, texture, and tensile properties. Metall Mater Trans A. 2013;44(1):323.

Tan YB, Wang XM, Ma M, Zhang JX, Liu WC, Fu RD, Xiang S. A study on microstructure and mechanical properties of AA3003 aluminum alloy joints by underwater friction stir welding. Mater Charact. 2017;127:41.

Vysotskiy I, Zhemchuzhnikova D, Malopheyev S, Mironov S, Kaibyshev R. Microstructure evolution and strengthening mechanisms in friction-stir welded Al–Mg–Sc alloy. Mater Sci Eng A. 2020. https://doi.org/10.1016/j.msea.2019.138540.

Canadinc D, Biyikli E, Niendorf T, Maier HJ. Experimental and numerical investigation of the role of grain boundary misorientation angle on the dislocation-grain boundary interactions. Adv Eng Mater. 2011;13(4):281.

Huang KT, Lui TS, Chen LH. Effect of microstructural feature on the tensile properties and vibration fracture resistance of friction stirred 5083 alloy. J Alloys Compd. 2011;509(27):7466.

Huo WT, Shi JT, Hou LG, Zhang JS. An improved thermo-mechanical treatment of high-strength Al–Zn–Mg–Cu alloy for effective grain refinement and ductility modification. J Mater Process Technol. 2017;239:303.

Terlinde G, Luetjering G. Influence of grain size and age-hardening on dislocation pile-ups and tensile fracture for a Ti–Al alloy. Metall Mater Trans A. 1982;13(7):1283.

Zhao YH, Bingert JF, Zhu YT, Liao XZ, Valiev RZ, Horita Z, Langdon TG, Zhou YZ, Lavernia EJ. Tougher ultrafine grain Cu via high-angle grain boundaries and low dislocation density. Appl Phys Lett. 2008;92(8):1.

Imam M, Ueji R, Fujii H. Effect of online rapid cooling on microstructure and mechanical properties of friction stir welded medium carbon steel. J Mater Process Technol. 2016;230:62.

Cam G, Mistikoglu S, Pakdil M. Microstructural and mechanical characterization of friction stir butt joint welded 63% Cu–37% Zn brass plate. Weld J. 2009;88:225.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51871093).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, YL., Xia, WJ., Yan, HG. et al. Microstructure and mechanical properties of friction-stir-welded high-Mg-alloyed Al–Mg alloy plates at different rotating rates. Rare Met. 40, 2167–2178 (2021). https://doi.org/10.1007/s12598-020-01558-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01558-3