Abstract

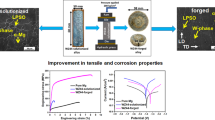

The increase in zinc content in Al–Zn–Mg–Cu alloys provides an effective method to enhance the strength. Transmission electron microscopy (TEM) and tensile test were employed to analyze the microstructure and tensile properties, respectively, of Al–9.3Zn–2.0Mg–1.8Cu alloy (9.3Zn alloy) and Al–9.8Zn–2.0Mg–1.8Cu alloy (9.8Zn alloy) with single- and double-stage aging states. The results showed that the two alloys possessed a closed strength under single-stage peak-aging treatment. As for double-stage aging treatment, 9.8Zn alloy had a higher strength values than 9.3Zn alloy under the same aging regimes. With the second step aging time prolonging, the strength gap was extended. The main precipitates for the two alloys with single-stage peak-aging state were GP zones and η′ phase, while there were a majority of η′ phases and η phases for the two alloys under typical double-stage over-aging state. Under double-stage over-aging state, the proportion of precipitate with large size for 9.3Zn alloy was larger than that for 9.8Zn alloy. Besides, a more obvious trend was revealed for the double-stage over-aging state. The gap of strength between the two alloys was explained by the difference of precipitation characteristics via interaction mechanism between precipitates and dislocations.

Graphic abstract

Similar content being viewed by others

References

Zhang X, Chen Y, Hu J. Recent advances in the development of aerospace materials. Prog Aerosp Sci. 2018;97:22.

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, Miller WS. Recent development in aluminium alloys for aerospace applications. Mater Sci Eng A. 2000;280(1):102.

Liu JT, Zhang YA, Li XW, Xiong BQ, Zhang JS. Phases and microstructures of high Zn-containing Al–Zn–Mg–Cu alloys. Rare Met. 2016;35(5):380.

Williams JC, Starke EA. Progress in structural materials for aerospace. Acta Mater. 2003;51(19):5775.

Kang L, Zhou Y, Zhao G, Liu K, Tian N. Prediction of properties distribution of 7B50 alloy thick plates after quenching and aging by quench factor analysis method. Rare Met. 2019;38(11):1043.

Huda Z, Edi P. Materials selection in design of structures and engines of supersonic aircrafts: a review. Mater Des. 2013;46:552.

Komarasamy M, Alagarsamy K, Ely L, Mishra RS. Characterization of 3″ through-thickness friction stir welded 7050-T7451 Al alloy. Mater Sci Eng A. 2018;716:55.

Hornbogen E. Hundred years of precipitation hardening. J Light Met. 2001;1(2):127.

Azarniya A, Taheri AK, Taheri KK. Recent advances in ageing of 7xxx series aluminum alloys: a physical metallurgy perspective. J Alloys Compd. 2019;781:945.

Li Y, Wang Q, Gao G, Li J, Wang Z, Xu G. Texture evolution and mechanical properties of Al–Mg–Si alloys at different intermediate annealing temperatures. Rare Met. 2019;38(10):937.

Zhang X, Chen S, Zhou L, Fan S, Chen H. Effect of composition on quenching sensitivity and microstructures-properties of super-strength Al–Zn–Mg–Cu aluminum alloys. Chin J Rare Met. 2019;43(6):561.

Dong P, Chen S, Chen K. Effects of Cu content on microstructure and properties of super-high-strength Al-9.3Zn-2.4Mg-xCu-Zr alloy. J Alloys Compd. 2019;788:329.

Xu D, Li Z, Wang G, Li X, Lv X, Zhang Y, Fan Y, Xiong B. Phase transformation and microstructure evolution of an ultra-high strength Al-Zn-Mg-Cu alloy during homogenization. Mater Charact. 2017;131:285.

Zhang H, Jin NP, Chen JH. Hot deformation behavior of Al-Zn-Mg-Cu-Zr aluminum alloys during compression at elevated temperature. Trans. Nonferr. Met. Soc. 2011;21(3):437.

Liu J, Zhang Y, Li X, Li Z, Xiong B, Zhang J. Thermodynamic calculation of high zinc-containing Al-Zn-Mg-Cu alloy. Trans. Nonferr. Met. Soc. 2014;24(5):1481.

Li S, Zhang H, Dai D, Ding G, Wei X, Guo Y. Study on the factors affecting solid solubility in binary alloys: an exploration by machine learning. J Alloys Compd. 2019;782:110.

Cao F, Zheng J, Jiang Y, Chen B, Wang Y, Hu T. Experimental and DFT characterization of η′ nano-phase and its interfaces in AlZnMgCu alloys. Acta Mater. 2019;164:207.

Jiang JT, Tang QJ, Yang L, Zhang K, Yuan SJ, Zhen L. Non-isothermal ageing of an Al–8Zn–2Mg–2Cu alloy for enhanced properties. J Mater Process Technol. 2016;227:110.

Liu Y, Jiang D, Li B, Ying T, Hu J. Heating aging behavior of Al–8.35Zn–2.5Mg–2.25 Cu alloy. Mater. Des. 2014;60:116.

Chun F, Liu Z, Ning A, Liu Y, Zeng S. Retrogression and re-aging treatment. Trans. Nonferr. Met. Soc. 2006;16(5):1163.

Wang F, Xiong B, Zhang Y, Zhu B, Liu H, He X. Effect of heat treatment on the microstructure and mechanical properties of the spray-deposited Al–10.8Zn–2.8Mg–1.9Cu alloy. Mater Sci Eng A. 2008;486:648.

Kalemba I, Hamilton C, Dymek S. Natural aging in friction stir welded 7136-T76 aluminum alloy. Mater Des. 2014;60:295.

Yuan D, Chen K, Zhou L, Chang J, Huang L, Yi Y. Enhancing stress corrosion cracking resistance of low Cu-containing Al-Zn-Mg-Cu alloys by slow quench rate. Mater Des. 2019;164:107.

Fang HC, Luo FH, Chen KH. Effect of intermetallic phases and recrystallization on the corrosion and fracture behavior of an Al-Zn-Mg-Cu-Zr-Yb-Cr alloy. Mater Sci Eng A. 2017;684:480.

Wen K, Xiong B, Zhang Y, Li Z, Li X, Huang S, Yan L, Yan H, Liu H. Over-aging influenced matrix precipitate characteristics improve fatigue crack propagation in a high Zn-containing Al-Zn-Mg-Cu alloy. Mater Sci Eng A. 2018;716:42.

Sha G, Cerezo A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004;52(15):4503.

Berg LK, Gjønnes J, Hansen V, Li XZ, Knutson-Wedel M, Waterloo G, Schryvers D, Wallenberg LR. GP-zones in Al-Zn-Mg alloys and their role in artificial aging. Acta Mater. 2001;49:3443.

Godard D, Archambault P, Aeby-Gautier E, Lapasset G. Precipitation sequences during quenching of the AA 7010 alloy. Acta Mater. 2002;50(9):2319.

Ringer SP, Hono K. Microstructural evolution and age hardening in aluminium alloys: atom probe field-ion microscopy and transmission electron microscopy studies. Mater Charact. 2000;44:101.

Buha J, Lumley RN, Crosky AG. Secondary ageing in an aluminium alloy 7050. Mater Sci Eng A. 2008;492(1–2):1.

Martin JW. Precipitation Hardening: Theory and Applications. Oxford: Butterworth-Heinemann; 2012. 82.

Shim JH, Voigt HJL, Wirth BD. Temperature dependent dislocation bypass mechanism for coherent precipitates in Cu–Co alloys. Acta Mater. 2016;110:276.

Acknowledgements

This study was financially supported by the National Key and Development Program of China (Nos. 2016YFB0300903 and 2016YFB0300803).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, K., Xiong, BQ., Zhang, YA. et al. Aging precipitation characteristics and tensile properties of Al–Zn–Mg–Cu alloys with different additional Zn contents. Rare Met. 40, 2160–2166 (2021). https://doi.org/10.1007/s12598-020-01495-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01495-1