Abstract

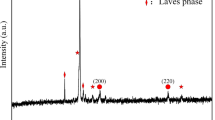

The defect-free CoCrNbNiW high-entropy alloy coating was successfully prepared by laser melting deposition, and its microstructure and wear resistance were investigated. The results showed that the microstructure of CoCrNbNiW high-entropy alloy coating consisted of fcc phase rich in Nb and fcc phase including un-melted W particles and rich in Cr. Moreover, an amount of fcc phase was formed at the middle and top of coating, while the bcc phase rich in Cr was formed at the bottom. Meanwhile, the un-melted W particles were diffusely distributed in the coating. Therefore, the microhardness of CoCrNbNiW high-entropy alloy coating was improved and was 2.78 times as high as that of substrate. The wear loss and wear rate of coating were 0.26 and 0.23 times higher than those of substrate, respectively. The wear resistance of substrate was obviously improved due to the preparation of CoCrNbNiW high-entropy alloy coating.

Graphic Abstract

Similar content being viewed by others

References

Cai Y, Young B. Carbon steel and stainless steel bolted connections undergoing unloading and re-loading processes. J Constr Steel Res. 2019;157:337.

Cordero Z, Knight B, Schuh C. Six decades of the Hall–Petch effect—a survey of grain-size strengthening studies on pure metals. Int Mater Rev. 2016;61(8):495.

Xu Y, Li M, Sun X, Liu M. Anticorrosive behaviors of phosphatized carbon steel in hot-dry-rock geothermal water. Surf Coat Technol. 2019;370:340.

Rodrigues J, Laim L. Comparing fire behaviour of restrained hollow stainless steel with carbon steel columns. J Constr Steel Res. 2019;153:44.

Fenili C, Souza F, Marin G, Probst S, Klein A. Corrosion resistance of low-carbon steel modified by plasma nitriding and diamond-like carbon. Diam Relat Mater. 2017;80:153.

Takata N, Kodaira H, Suzuki A, Kobashi M. Size dependence of microstructure of AlSi10Mg alloy fabricated by selective laser melting. Mater Charact. 2018;143:18.

Buendia C, Fromel F, Wilms M, Streubel R, Tenkamp J, Hupfeld T, Nachev M, Gokce E, Weisheit A, Barcikowski S, Walther F, Schleifenbaum J, Gokce B. Oxide dispersion-strengthened alloys generated by laser metal deposition of laser-generated nanoparticle-metal powder composites. Mater Des. 2018;154:360.

Wang D, Yang X, Liao Q, Peng H, Wen Y. Significant improvement of shape memory effect in Co–Ni-based alloys through Si alloying. J Alloy Compd. 2019;791:501.

Qiao C, Shen L, Hao L, Mu X, Liu B. A study on the initial corrosion behavior of carbon steel exposed to a simulated coastal-industrial atmosphere. Acta Metall Sin. 2018;54(1):65.

Zhaia L, Bana C, Zhang J. Investigation on laser cladding Ni-base coating assisted by electromagnetic field. Opt Laser Technol. 2019;114:81.

Musil J, Jaros M, Kos S. Superhard metallic coatings. Mater Lett. 2019;247:32.

Guo L, Dai Q, Huang W, Wang X. Composite Ni/UHMWPE coatings and their tribological performances. Appl Surf Sci. 2019;481:414.

Zhao Z, Hui P, Liu F, Wang X, Li B, Xu Y, Zhong L, Zhao M. Fabrication of TaC coating on tantalum by interstitial carburization. J Alloy Compd. 2019;790:189.

Xie L, Xiong X, Zeng Y, Wang Y. The wear properties and mechanism of detonation sprayed iron-based amorphous coating. Surf Coat Technol. 2019;366:146.

Li H, Zhang C, Liu C, Huang M. Improvement in corrosion resistance of CrN coatings. Surf Coat Technol. 2019;365:158.

Yoshida S, Bhattacharjee T, Bai Y, Tsuji N. Friction stress and Hall–Petch relationship in CoCrNi equi-atomic medium entropy alloy processed by severe plastic deformation and subsequent annealing. Scripta Mater. 2017;134:33.

Ma S, Zhang Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater Sci Eng A. 2012;532:480.

Shu F, Zhang B, Liu T, Sui S, Liu Y, He P, Liu B, Xu B. Effects of laser power on microstructure and properties of laser cladded CoCrBFeNiSi high-entropy alloy amorphous coatings. Surf Coat Technol. 2019;358:667.

Shang C, Axinte E, Sun J, Li X, Li P, Du J, Qiao P, Wang Y. CoCrFeNi(W1−xMox) high-entropy alloy coatings with excellent mechanical properties and corrosion resistance prepared by mechanical alloying and hot pressing sintering. Mater Des. 2017;117:193.

Jiang Y, Li J, Juan Y, Lu Z, Jia W. Evolution in microstructure and corrosion behavior of AlCoCrxFeNi high-entropy alloy coatings fabricated by laser cladding. J Alloy Compd. 2019;775:1.

Li X, Feng Y, Liu B, Yi D, Yang X, Zhang W, Chen G, Liu Y, Bai P. Influence of NbC particles on microstructure and mechanical properties of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. J Alloy Compd. 2019;788:485.

Ni C, Shi Y, Liu J, Huang G. Characterization of Al0.5FeCu0.7NiCoCr high-entropy alloy coating on aluminum alloy by laser cladding. Opt Laser Technol. 2018;105:257.

Dobbelstein H, Gurevich E, George E, Ostendorf A, Laplanche G. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy. Addit Manuf. 2018;24:386.

Chang R, Fang W, Bai X, Xia C, Zhang X, Yu H, Liu B, Yin F. Effects of tungsten additions on the microstructure and mechanical properties of CoCrNi medium entropy alloys. J Alloy Compd. 2019;790:732.

Miracle D, Senkov O. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448.

Tian Y, Shen Y, Lu C, Feng X. Microstructures and oxidation behavior of Al–CrMnFeCoMoW composite coatings on Ti–6Al–4V alloy substrate via high-energy mechanical alloying method. J Alloy Compd. 2019;779:456.

Hu Y, Liu X, Guo N, Wang L, Su Y, Guo J. Microstructure and mechanical properties of NbZrTi and NbHfZrTi alloys. Rare Met. 2019;38(9):840.

Wang Q, Xi Y, Zhao Y, Liu S, Bai S, Liu Z. Effects of laser re-melting and annealing on microstructure, mechanical property and corrosion resistance of Fe-based amorphous/crystalline composite coating. Mater Charact. 2017;127:239.

Tian W, Yang H, Zhang S. Synergistic effect of Mo, W, Mn and Cr on the passivation behavior of a Fe-based amorphous alloy coating. Acta Metall Sin. 2018;31(3):308.

Takeuchi A, Inoue A. Special issue on materials science of bulk metallic glasses—classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans. 2005;12:2818.

Zhao S, Zhou S, Xie M, Dai X, Chen D, Zhang L. Phase separation and enhanced wear resistance of Cu88Fe12 immiscible coating prepared by laser cladding. J Mater Res Technol. 2019;8:2001.

Rabadia C, Liu Y, Wang L, Sun H, Zhang L. Laves phase precipitation in Ti–Zr–Fe–Cr alloys with high strength and large plasticity. Mater Des. 2018;154:228.

Haque M, Sharif A. Study on wear properties of aluminium-silicon piston alloy. J Mater Process Technol. 2001;118:69.

Huang W, Wang W, Zhang H, Shi S, Xie P. Precipitated phase of titanium alloy with adding Nd elements. Chin J Rare Met. 2017;41(3):245.

Shao H, Qu J. Friction and wear. Beijing: Metallurgical Industry Press; 1988. 120.

Acknowledgements

This study was financially supported by the National Key R&D Program of China (No. 2017YFB1103604).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jia, YJ., Chen, HN. & Liang, XD. Microstructure and wear resistance of CoCrNbNiW high-entropy alloy coating prepared by laser melting deposition. Rare Met. 38, 1153–1159 (2019). https://doi.org/10.1007/s12598-019-01342-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01342-y