Abstract

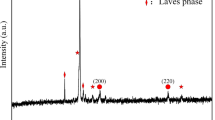

AlCoCrFeNiTi0.5 high entropy alloy (HEA) coating with high hardness and excellent wear resistance was deposited on TC4 surface by electron beam cladding, and the process parameters, microstructure and properties of the coating were studied. The analysis shows that the microstructure of HEA coating is composed of dendritic (DR) and interdendritic (IR) phases. The IR phase, which is mainly composed of Fe and Cr, is confirmed to be BCC solid solution, while the DR phase is FCC solid solution with AlNi2Ti (or AlCo2Ti) structure. The grain orientation of the HEA coating is random, without obvious texture. Hardness gradually decreases from the upper part area of the HEA coating to the inner of the TC4 substrate. The hardness curve in the HEA coating region has some fluctuations, but the fluctuations are small, indicating a homogeneous microstructure. The average hardness of the HEA coating is 796.18 HV0.2, which is about 2.6 times that of the TC4 substrate. The HEA coating exhibits a higher coefficient of friction (COF) compared to the TC4 substrate. The average COF of HEA coating and TC4 substrate in the stable stage are 0.57 and 0.48, respectively. Wear loss of the HEA coating is 0.0657 mm3, about one tenth of that of TC4 substrate (0.6112 mm3). The hardness of the HEA coating is high, no obvious furrow is found, and its wear mechanism is considered to be a mixture of adhesive wear and oxidation wear.

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

M.-H. Tsai and J.-W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2, p 107–123. https://doi.org/10.1080/21663831.2014.912690

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299–303. https://doi.org/10.1002/adem.200300567

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004 https://doi.org/10.1016/j.msea.2003.10.257

L. Hou, J. Hui, Y. Yao, J. Chen, and J. Liu, Effects of Boron Content on Microstructure and Mechanical Properties of AlFeCoNiBx High Entropy Alloy Prepared by Vacuum Arc Melting, Vacuum, 2019, 164, p 212–218. https://doi.org/10.1016/j.vacuum.2019.03.019

T. Yang, Y.L. Zhao, Y. Tong, Z.B. Jiao, J. Wei, J.X. Cai, X.D. Han, D. Chen, A. Hu, J.J. Kai, K. Lu, Y. Liu, and C.T. Liu, Multicomponent Intermetallic Nanoparticles and Superb Mechanical Behaviors of Complex Alloys, Science, 2018, 362, p 933–937. https://doi.org/10.1126/science.aas8815

Z. Xu, D.Y. Li, and D.L. Chen, Effect of Ti on the Wear Behavior of AlCoCrFeNi High-Entropy Alloy During Unidirectional and Bi-Directional Sliding Wear Processes, Wear, 2021 https://doi.org/10.1016/j.wear.2021.203650

M. Pole, M. Sadeghilaridjani, J. Shittu, A. Ayyagari, and S. Mukherjee, High Temperature Wear Behavior of Refractory High Entropy Alloys Based on 4-5-6 Elemental Palette, J. Alloys Compd., 2020 https://doi.org/10.1016/j.jallcom.2020.156004

R. Zhou, G. Chen, B. Liu, J. Wang, L. Han, and Y. Liu, Microstructures and Wear Behaviour of (FeCoCrNi)1–x(WC)x High Entropy Alloy Composites, Int. J. Refract. Metal Hard Mater., 2018, 75, p 56–62. https://doi.org/10.1016/j.ijrmhm.2018.03.019

P. Muangtong, A. Rodchanarowan, D. Chaysuwan, N. Chanlek, and R. Goodall, The Corrosion Behaviour of CoCrFeNi-x (x = Cu, Al, Sn) High Entropy Alloy Systems in Chloride Solution, Corros. Sci., 2020 https://doi.org/10.1016/j.corsci.2020.108740

Y.Y. Liu, Z. Chen, J.C. Shi, Z.Y. Wang, and J.Y. Zhang, The Effect of Al Content on Microstructures and Comprehensive Properties in AlxCoCrCuFeNi High Entropy Alloys, Vacuum, 2019, 161, p 143–149. https://doi.org/10.1016/j.vacuum.2018.12.009

S.E. Sünbül, K. İçi̇n, F.Z. Şeren, Ö. Şahin, D.D. Cakil, R. Sezer, and S. Öztürk, Determination of Structural, Tribological, Isothermal Oxidation and Corrosion Properties of Al–Co–Cr–Fe–Ni–Ti–Cu High-Entropy Alloy, Vacuum, 2021, 187, p 110072. https://doi.org/10.1016/j.vacuum.2021.110072

R. Gawel, Ł Rogal, J. Dąbek, M. Wójcik-Bania, and K. Przybylski, High Temperature Oxidation Behaviour of Non-Equimolar AlCoCrFeNi High Entropy Alloys, Vacuum, 2021 https://doi.org/10.1016/j.vacuum.2020.109969

S. Wang, Z. Chen, P. Zhang, K. Zhang, C.L. Chen, and B.L. Shen, Influence of Al Content on High Temperature Oxidation Behavior of AlxCoCrFeNiTi0.5 High Entropy Alloys, Vacuum, 2019, 163, p 263–268. https://doi.org/10.1016/j.vacuum.2019.01.053

M. Lobel, T. Lindner, T. Mehner, and T. Lampke, Influence of Titanium on Microstructure, Phase Formation and Wear Behaviour of AlCoCrFeNiTi(x) High-Entropy Alloy, Entropy, 2018 https://doi.org/10.3390/e20070505

D. Kong, J. Guo, R. Liu, X. Zhang, Y. Song, Z. Li, F. Guo, X. Xing, Y. Xu, and W. Wang, Effect of Remelting and Annealing on the Wear Resistance of AlCoCrFeNiTi0.5 High Entropy Alloys, Intermetallics, 2019 https://doi.org/10.1016/j.intermet.2019.106560

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Solid Solution Alloys of AlCoCrFeNiTix with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007 https://doi.org/10.1063/1.2734517

Y.J. Zhou, Y. Zhang, and Y.L. Wang, Solid Solution Alloys of AlCoCrFeNiTiX with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007, 90, p 181904.

X. Zeng, Z. Liu, G. Wu, X. Tong, Y. Xiong, X. Cheng, X. Wang, and T. Yamaguchi, Microstructure and High-Temperature Properties of Laser Cladded AlCoCrFeNiTi0.5 High-Entropy Coating on Ti 6Al-4V Alloy, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127243

W.Y. Cui, W. Li, W.T. Chen, and F. Liou, Laser Metal Deposition of an AlCoCrFeNiTi0.5 High-Entropy Alloy Coating on a Ti6Al4V Substrate, Microstruct. Oxidat. Behav. Cryst., 2020, 10, p 638.

Y.J. Zhou, Y. Zhang, T.N. Kim, and G.L. Chen, Microstructure Characterizations and Strengthening Mechanism of Multi-Principal Component AlCoCrFeNiTi0.5 Solid Solution Alloy with Excellent Mechanical Properties, Mater. Lett., 2008, 62, p 2673–2676. https://doi.org/10.1016/j.matlet.2008.01.011

G. Liu, C. Xu, H. Chen, X. Hou, and Y. Liu, Electroless Deposition Method for Silver-Coated Carbon Fibres, Micro Nano Lett., 2015, 10, p 315–317. https://doi.org/10.1049/mnl.2014.0620

G. Zhao, Y. Zou, H. Zhang, and Z. Zou, Correlation Between Corrosion Resistance and the Local Atomic Structure of Electroless, Annealed Ni–P Amorphous Alloys, Mater. Lett., 2014, 132, p 221–223. https://doi.org/10.1016/j.matlet.2014.06.081

H. Luo, Q. Cai, B. Wei, B. Yu, D. Li, J. He, and Z. Liu, Effect of (NaPO3)6 Concentrations on Corrosion Resistance of Plasma Electrolytic Oxidation Coatings Formed on AZ91D Magnesium Alloy, J. Alloy. Compd., 2008, 464, p 537–543. https://doi.org/10.1016/j.jallcom.2007.10.072

A. Anupam, R.S. Kottada, S. Kashyap, A. Meghwal, B.S. Murty, C.C. Berndt, and A.S.M. Ang, Understanding the Microstructural Evolution of High Entropy Alloy Coatings Manufactured by Atmospheric Plasma Spray Processing, Appl. Surf. Sci., 2020 https://doi.org/10.1016/j.apsusc.2019.144117

W. Wang, W. Qi, L. Xie, X. Yang, J. Li, and Y. Zhang, Microstructure and Corrosion Behavior of (CoCrFeNi)(95)Nb(5) High-Entropy Alloy Coating Fabricated by Plasma Spraying, Materials, 2019 https://doi.org/10.3390/ma12050694

M. Srivastava, M. Jadhav, R.P.S. Chakradhar, M. Muniprakash, and S. Singh, Synthesis and Properties of High Velocity Oxy-Fuel Sprayed FeCoCrNi2Al High Entropy Alloy Coating, Surf. Coat. Technol., 2019 https://doi.org/10.1016/j.surfcoat.2019.124950

L. Chen, Y. Wang, X. Hao, X. Zhang, and H. Liu, Lightweight Refractory High Entropy Alloy Coating by Laser Cladding on Ti–6Al–4V Surface, Vacuum, 2021 https://doi.org/10.1016/j.vacuum.2020.109823

Y. Cui, J. Shen, S.M. Manladan, K. Geng, and S. Hu, Wear Resistance of FeCoCrNiMnAlx High-Entropy Alloy Coatings at High Temperature, Appl. Surf. Sci., 2020 https://doi.org/10.1016/j.apsusc.2020.145736

J. Cheng, B. Sun, Y. Ge, X. Hu, L. Zhang, X. Liang, and X. Zhang, Nb Doping in Laser-cladded Fe25Co25Ni25(B0.7Si0.3)25 High Entropy Alloy Coatings: Microstructure Evolution and Wear Behavior, Surf. Coat. Technol., 2020 https://doi.org/10.1016/j.surfcoat.2020.126321

G.H. Meng, N.A. Protasova, E.P. Kruglov, X. Lin, H. Xie, and X. Ding, Solidification Behavior and Morphological Evolution in Laser Surface Forming of AlCoCrCuFeNi Multi-Layer High-Entropy Alloy Coatings on AZ91D, J. Alloy. Compd., 2019, 772, p 994–1002. https://doi.org/10.1016/j.jallcom.2018.09.120

Q. Fan, C. Chen, C. Fan, Z. Liu, X. Cai, S. Lin, and C. Yang, Ultrasonic Suppression of Element Segregation in Gas Tungsten Arc Cladding AlCoCuFeNi High-Entropy Alloy Coatings, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127364

Q. Fan, C. Chen, C. Fan, Z. Liu, X. Cai, S. Lin, and C. Yang, Effect of High Fe Content on the Microstructure, Mechanical and Corrosion Properties of AlCoCrFeNi High-Entropy Alloy Coatings Prepared by Gas Tungsten Arc Cladding, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127242

G. Dai, S. Wu, and X. Huang, Preparation Process for High-Entropy Alloy Coatings based on Electroless Plating and Thermal Diffusion, J. Alloy. Compd., 2022 https://doi.org/10.1016/j.jallcom.2022.163736

A. Vallimanalan, S.P.K. Babu, S. Muthukumaran, M. Murali, V. Gaurav, and R. Mahendran, Corrosion Behaviour of Thermally Sprayed Mo Added AlCoCrNi High Entropy Alloy Coating, Mater. Today Proc., 2020, 27, p 2398–2400. https://doi.org/10.1016/j.matpr.2019.09.149

S. Li and T. Yamaguchi, High-Temperature Oxidation Performance of Laser-Cladded Amorphous TiNiSiCrCoAl High-Entropy Alloy Coating on Ti-6Al-4V Surface, Surf. Coat. Technol., 2022 https://doi.org/10.1016/j.surfcoat.2022.128123

H. Liu, Q. Gao, J. Dai, P. Chen, W. Gao, J. Hao, and H. Yang, Microstructure and High-Temperature Wear Behavior of CoCrFeNiWx High-Entropy Alloy Coatings Fabricated by Laser Cladding, Tribol. Int., 2022 https://doi.org/10.1016/j.triboint.2022.107574

X.W. Tao, Z.J. Yao, S.S. Zhang, J. Liao, and J. Liang, Investigation on Microstructure, Mechanical and Tribological Properties of In-Situ (TiB + TiC)/Ti Composite During the Electron Beam Surface Melting, Surf. Coat. Technol., 2018, 337, p 418–425. https://doi.org/10.1016/j.surfcoat.2018.01.054

O.B. Perevalova, A.V. Panin, and M.S. Kazachenok, Concentration-Dependent Transformation Plasticity Effect During Hydrogenation of Technically Pure Titanium Irradiated with an Electron Beam, Russ. Phys. J., 2019, 61, p 1992–2000. https://doi.org/10.1007/s11182-019-01629-8

T. Yu, H. Wang, K. Han, and B. Zhang, Microstructure and Wear Behavior of AlCrTiNbMo High-Entropy Alloy Coating Prepared by Electron Beam Cladding on Ti600 Substrate, Vacuum, 2022 https://doi.org/10.1016/j.vacuum.2022.110928

T. Yu, H. Wang, K. Han, Y. Wang, Y. Qiu, and B. Zhang, Mo20Nb20Co20Cr20(Ti8Al8Si4) Refractory High-Entropy Alloy Coatings Fabricated by Electron Beam Cladding: Microstructure and Wear Resistance, Intermetallics, 2022 https://doi.org/10.1016/j.intermet.2022.107669

A.A. Ruktuev, D.V. Lazurenko, T.S. Ogneva, R.I. Kuzmin, M.G. Golkovski, and I.A. Bataev, Structure and Oxidation Behavior of CoCrFeNiX (where X is Al, Cu, or Mn) Coatings Obtained by Electron Beam Cladding in Air Atmosphere, Surf. Coat. Technol., 2022 https://doi.org/10.1016/j.surfcoat.2022.128921

I.A. Bataev, D.O. Mul, A.A. Bataev, O.G. Lenivtseva, M.G. Golkovski, Y.S. Lizunkova, and R.A. Dostovalov, Structure and Tribological Properties of Steel After Non-Vacuum Electron Beam Cladding of Ti, Mo and Graphite Powders, Mater. Charact., 2016, 112, p 60–67. https://doi.org/10.1016/j.matchar.2015.11.028

S. Guo, Q. Hu, C. Ng, and C.T. Liu, More than Entropy in High-Entropy Alloys: Forming Solid Solutions or Amorphous Phase, Intermetallics, 2013, 41, p 96–103. https://doi.org/10.1016/j.intermet.2013.05.002

V. Shivam, Y. Shadangi, J. Basu, and N.K. Mukhopadhyay, Alloying Behavior and Thermal Stability of Mechanically Alloyed Nano AlCoCrFeNiTi High-Entropy Alloy, J. Mater. Res., 2019, 34, p 787–795. https://doi.org/10.1557/jmr.2019.5

Z. Xiong, S. Liu, X. Wang, C. Shang, X. Li, and R.D.K. Misra, The Contribution of Intragranular Acicular Ferrite Microstructural Constituent on Impact Toughness and Impeding Crack Initiation and Propagation in the Heat-Affected Zone (HAZ) of Low-Carbon Steels, Mater. Sci. Eng., A, 2015, 636, p 117–123. https://doi.org/10.1016/j.msea.2015.03.090

Y. Cai, L. Zhu, Y. Cui, M. Shan, H. Li, Y. Xin, and J. Han, Fracture and Wear Mechanisms of FeMnCrNiCo+x(TiC) Composite High-Entropy Alloy Cladding Layers, Appl. Surf. Sci., 2021 https://doi.org/10.1016/j.apsusc.2020.148794

B. Bax, M. Schäfer, C. Pauly, and F. Mücklich, Coating and Prototyping of Single-Phase Iron Aluminide by Laser Cladding, Surf. Coat. Technol., 2013, 235, p 773–777. https://doi.org/10.1016/j.surfcoat.2013.09.001

Acknowledgments

This work was sponsored by the National Natural Science Foundation of China (52065043), the Central Guidance on Local: Construction of regional innovation system-Cross Regional R & D cooperation projects (20221ZDH04054), Technology Innovation High Level Talent Project of Double Thousand Plan of Jiangxi Province (jxsq2019201048), Natural Science Foundation of Chongqing (CSTB2022NSCQ-MSX1346).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Tang, B., Wu, H. et al. Microstructure and Wear Behavior of AlCoCrFeNiTi0.5 High Entropy Alloy Coating Prepared by Electron Beam Cladding on Ti-6Al-4V Substrate. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08753-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08753-0