Abstract

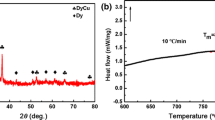

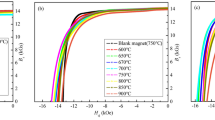

A grain boundary diffusion process (GBDP) was adopted to improve magnetic properties of Dy-free highly coercive Nd–Fe–B permanent magnet by coating thin layers of Nd and Cu in grain boundaries. For GBDP of Nd and Cu, Nd and Cu were coated by wet process, e.g., electrochemical and electroless on Nd–Fe–B magnets, which was fabricated by hot-deformed/die-upset with melt-spun specimen. Heat treatment was performed for 20 min at 600 °C followed by several different cooling conditions. The cooling conditions after heat treatment were varied to understand distribution and microstructural effects of Nd and Cu species in grain boundaries. The coercivity increased from 1.565 to 1.637 T in oil cooling rate but remanence decreased, while remanence jumped with little decrease in coercivity in furnace cooling. Microstructure analyses suggested that the coercivity was closely related to the cooling rate as well as distribution of Nd. The mechanism of coercivity enhancement due to the cooling rate was discussed based on the results presented here and those in the literature.

Similar content being viewed by others

References

Wan F, Han J, Zhang Y, Zhang X, Yang J, Yang Y. Coercivity enhancement of anisotropic die-upset Nd-Fe-B powders by Pr-Cu alloy diffusion. J Appl Phys. 2013;113(19):193902.

Cha HR, Yu JH, Back YK, Kwon HW, Kim TH, Yang CW, Lim TS, Kim YD, Lee JG. Effect of the dehydrogenation speed and Nd content on the microstructure and magnetic properties of HDDR processed Nd–Fe–B magnets. Met Mater Int. 2014;20(5):909.

Liu WQ, Chang C, Yue M, Yang JS, Zhang DT, Zhang JX, Liu YQ. Coercivity, microstructure, and thermal stability of sintered Nd–Fe–B magnets by grain boundary diffusion with TbH3 nanoparticles. Rare Met. 2017;36(9):718.

Hono K, Sepehri-Amin H. Strategy for high-coercivity Nd–Fe–B magnets. Scr Mater. 2012;67(6):530.

Li W, Ohkubo T, Hono K, Nishiuchi T, Hirosawa S. Coercivity mechanism of hydrogenation disproportionation desorption recombination processed Nd–Fe–B based magnets. Appl Phys Lett. 2008;93(5):052505.

Hrkac G, Woodcock T, Butler K, Saharan L, Bryan M, Schrefl T, Gutfleisch O. Impact of different Nd-rich crystal-phases on the coercivity of Nd–Fe–B grain ensembles. Scr Mater. 2014;70(1):35.

Kim JW, Kim SH, Song SY, Kim YD. Nd–Fe–B permanent magnets fabricated by low temperature sintering process. J Alloys Compd. 2013;551:180.

Lee S, Kwon J, Cha HR, Kim KM, Kwon HW, Lee J, Lee D. Enhancement of coercivity in sintered Nd–Fe–B magnets by grain-boundary diffusion of electrodeposited Cu–Nd alloys. Met Mater Int. 2016;22(2):340.

Zhou Q, Liu ZW, Zhong XC, Zhang GQ. Properties improvement and structural optimization of sintered NdFeB magnets by non-rare earth compound grain boundary diffusion. Mater Des. 2015;86:114.

Sepehri-Amin H, Ohkubo T, Shima T, Hono K. Grain boundary and interface chemistry of an Nd–Fe–B-based sintered magnet. Acta Mater. 2012;60(3):819.

Sepehri-Amin H, Ohkubo T, Nishiuchi T, Hirosawa S, Hono K. Coercivity enhancement of hydrogenation–disproportionation–desorption–recombination processed Nd–Fe–B powders by the diffusion of Nd–Cu eutectic alloys. Scr Mater. 2010;63(11):1124.

Liu L, Sepehri-Amin H, Ohkubo T, Yano M, Kato A, Shoji T, Hono K. Coercivity enhancement of hot-deformed Nd–Fe–B magnets by the eutectic grain boundary diffusion process. J Alloys Compd. 2016;666:432.

Kim T, Lee S, Kim H, Lee M, Jang T. Simultaneous application of Dy–X (X = F or H) powder doping and dip-coating processes to Nd–Fe–B sintered magnets. Acta Mater. 2015;93:95.

Vial F, Joly F, Nevalainen E, Sagawa M, Hiraga K, Park KT. Improvement of coercivity of sintered NdFeB permanent magnets by heat treatment. J Magn Magn Mater. 2002;242:1329.

Khlopkov K, Gutfleisch O, Schäfer R, Hinz D, Müller KH, Schultz L. Interaction domains in die-upset NdFeB magnets in dependence on the degree of deformation. J Magn Magn Mater. 2004;272:E1937.

Tang X, Chen R, Yin W, Wang J, Tang X, Lee D, Yan A. Enhanced texture in die-upset nanocomposite magnets by Nd-Cu grain boundary diffusion. Appl Phys Lett. 2013;102(7):072409.

Kwon HW, Yu JH. Texture studies on die-upset Nd-lean Nd-Fe-(Cu)-Ga-B alloy. IEEE Trans Magn. 2012;45(10):4435.

Liu YG, Xu L, Wang QF, Li W, Zhang XY. Development of crystal texture in Nd-lean amorphous Nd9Fe85B6 under hot deformation. Appl Phys Lett. 2009;94(17):172502.

Gabay AM, Zhang Y, Hadjipanayis GC. Effect of Cu and Ga additions on the anisotropy of R2Fe14B/alpha-Fe nanocomposite die-upset magnets (R = Pr, Nd). J Magn Magn Mater. 2006;302(1):244.

Hirota K, Nakamura H, Minowa T, Honshima M. Coercivity enhancement by the grain boundary diffusion process to Nd-Fe-B sintered magnets. IEEE Trans Magn. 2006;42(10):2909.

Nakamura H, Hirota K, Shimao M, Minowa T, Honshima M. Magnetic properties of extremely small Nd–Fe–B sintered magnets. IEEE Trans Magn. 2005;41(10):3844.

Cha HR, Yoo JG, Baek YK, Kim DH, Kwon HW, Kim YD, Lee D, Lee J. Coercivity enhancement of Nd–Fe–B HDDR powder by grain boundary diffusion process with rare-earth hydride. JOM. 2018;70(5):661.

Bae K, Kim T, Lee S, Kim H, Lee M, Jang T. Magnetic and microstructural characteristics of DyF3/DyHx dip-coated Nd-Fe-B sintered magnets. J Alloys Compd. 2014;612:183.

Dong X, Wang D, Zeng Y. Effect of mechanical attrition on microstructure and properties of electro-deposition coatings on NdFeB. J Rare Earths. 2014;32(9):867.

Monk P, Janes R, Partridge RD. Speciation modelling of the electroprecipitation of rare-earth cuprate and nickelate materials-speciation of aqueous solutions not at equilibrium. J Chem Soc Faraday Trans. 1997;93(22):3991.

Monk P, Janes R, Partridge RD. Speciation analysis applied to the electrodeposition of precursors of neodymium cuprate and related phases—first application of speciation modelling to a solution not at equilibrium. J Chem Soc Faraday Trans. 1997;93(22):3985.

Matsuura M, Sugimoto S, Goto R, Tezuka N. Interfacial state and magnetic properties of Nd-Fe-B/Nd thin films. J Appl Phys. 2009;105(7):07A741.

Yang H, Mao S, Song Z. The effect of absorbed hydrogen on the corrosion behavior of sintered NdFeB magnet. Mater Corros. 2012;63(4):292.

Straumal BB, Kucheev YO, Yatskovskaya IL, Mogilnikova IV, Schutz G, Nekrasov AN, Baretzky B. Grain boundary wetting in the NdFeB-based hard magnetic alloys. J Mater Sci. 2012;47(24):8352.

Straumal BB, Mazilkin AA, Protasova SG, Schütz G, Straumal AB, Baretzky B. Observation of pseudopartial grain boundary wetting in the NdFeB-based alloy. J Mater Eng Perform. 2016;25(8):3303.

Acknowledgements

This research was financially supported by the National Research Foundation of Korea (No. 2015R1A2A2A01 002795), the Fundamental R&D Program for Core Technology of Materials funded by the Ministry of Trade, Industry, and Energy, Republic of Korea (No. 10080382) and the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (No. 2018R1D1A1B07041358).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, J., Lee, D., Yoo, D. et al. Enhancement of magnetic properties of hot pressed/die-upset Dy-free Nd–Fe–B magnets with Cu/Nd coating by wet process. Rare Met. 39, 48–54 (2020). https://doi.org/10.1007/s12598-019-01277-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01277-4