Abstract

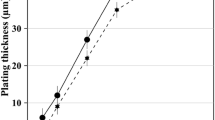

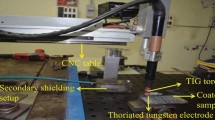

In order to reduce the friction coefficient of a pure nickel coating and extend the lifetime of metal parts under extreme friction conditions, a series of Ni-based WS2-composite solid lubrication coating containing different WS2 concentrations were prepared on a 45# mild carbon steel substrate by electroplating. The cyclic voltammetry method was used to investigate the electroplating regulation of the Ni-WS2 composite coatings. X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to analyze the microstructures and wear surfaces of the composite coatings, the tribological properties and wear mechanisms of the composite coatings with different WS2 concentrations. The results show that the addition of WS2 can promote the cathode polarization of the electroplating process, and the polarization degree goes up with the increase in WS2 concentrations. The friction coefficient of Ni-composite coatings significantly decreases by the addition of WS2 particles. The lowest friction coefficient at room temperature is obtained at a value around 0.01–0.03 from the coating deposited in the electrolyte solution with a 30 g·L−1 WS2 concentration. The friction coefficient of the Ni-WS2 composite coating remains in 0.01–0.03 with the increase in temperature from room temperature to 300 °C. When the temperature goes up to 500 °C, the friction coefficient manifests a continuous increase to 0.12, because WS2 is gradually oxidized into WO3 and therefore loses its lubrication ability.

Similar content being viewed by others

References

He Y, Wang SC, Walsh FC, Li WS, He L, Reed PAS. The monitoring of coating health by in situ luminescent layers. RSC Adv. 2015;5(53):42965.

Guo YX, Liu QB, Zhou F. Microstructure and wear resistance of high-melting-point AlCrFeMoNbxTiW high-entropy alloy coating by laser cladding. Chin J Rare Met. 2017;41(12):1327.

Aouadi SM, Singh DP, Stone DS, Polychronopoulou K, Nahif F, Rebholz C, Muratore C, Voevodin AA. Adaptive VN/Ag nanocomposite coatings with lubricious behavior from 25 to 1000 °C. Acta Mater. 2010;58(16):5326.

Li JL, Cai GY, Zhong HS, Wang YX, Chen JM. Tribological properties in seawater for Ti/TiCN coatings on Ti6Al4V alloy by arc ion plating with different carbon contents. Rare Met. 2017;36(11):1.

Shi ZT, Zhao HB, Chen XQ, Wu GM, Wei F. Chemical vapor deposition growth and transport properties of MoS2–2H thin layers using molybdenum and sulfur as precursors. Rare Met. 2015. https://doi.org/10.1007/s12598-015-0599-x.

Qu WT, Sun XG, Yuan BF. Tribological behaviour of biomedical Ti–Zr-based shape memory alloys. Rare Met. 2017;36(6):478.

Muratore C, Voevodin AA. Molybdenum disulfide as a lubricant and catalyst in adaptive nanocomposite coatings. Surf Coat Technol. 2006;201(7):4125–30.

Karthikeyan S, Jeeva PA, Arivazhagan N, Umasankar V, Srinivasan KN, Paramasivam M. Wear, hardness and corrosion resistance characteristics of tungsten sulfide incorporated electroless Ni–P coatings. Proced Eng. 2013;64(4):720.

Redlich M, Gorodnev A, Feldman Y, Kaplanashiri I, Tenne R, Fleischer N, Genut M, Feuerstein N. Friction reduction and wear resistance of electro-co-deposited inorganic fullerene-like WS2 coating for improved stainless steel orthodontic wires. J Mater Res. 2008;23(11):2909.

Komarneni MR, Yu ZQ, Burghaus U, Tsverin Y, Zak A, Feldman Y, Tenne R. Characterization of Ni-coated WS2 nanotubes for hydrodesulfurization catalysis. Isr J Chem. 2012;52(11–12):1053.

Zhang WB, Liu XZ, Chen ZH, Chen D, Peng C. Latest development of WC-Co cemented carbide. Chin J Rare Met. 2015;39(2):178.

Sivandipoor I, Ashrafizadeh F. Synthesis and tribological behaviour of electroless Ni–P–WS2 composite coatings. Appl Surf Sci. 2012;263(48):314.

Sangeetha S, Kalaignann PG. Tribological and electrochemical corrosion behavior of Ni–W/BN (hexagonal) nano-compositecoatings. Ceram Int. 2015;41(9):10415.

Huang YS, Zeng XT, Hu XF, Liu FM. Corrosion resistance properties of electroless nickel composite coatings. Electrochim Acta. 2004;49(25):4313.

Sun J, Li CS, Ji L, Tang H, Zhang Y, Li XC. Growth and mechanical properties of MoS2/WS2 composite films by magnetron sputtering. Chin J Vac Sci Technol. 2009;4(29):398.

Zhou L, Yin GL, Wang YD, Yu Z, He DN. Tribological and wear properties of reaction-sputtered WS2/MoS2/C composite films. Chin J Nonferrous Met. 2010;3(20):483.

Tsuru Y, Nomura M, Foulkes FR. Effects of boric acid on hydrogen evolution and internal stress in films deposited from a nickel sulfamate bath. J Appl Electrochem. 2002;32(6):629.

Timoshkov I, Kurmashev V, Timoshkov V. Electroplated nanocomposites of high wear resistance for advanced systems application. In: Hashim A, editor. Advances in Nanocomposite Technology. Rijeka: InTech; 2011. 81.

Kuo SL. The influence of process parameters on the MoS2 content of Ni-MoS2 composite coating by the robust design method. J Chin Inst Eng. 2004;27(2):243.

Shrestha NK, Sakurada K, Masuko M, Saji T. Composite coatings of nickel and ceramic particles prepared in two steps. Surf Coat. 2001;140(2):175.

EBRU Saraloğlu GÜLER. Electro co-deposition of molybdenum disulfide particles in nickel matrix. Ankara: Middle East Technical University; 2013. 22.

Hui J, Zhu YW, Zhu CH, Liu YF. Dispersion characteristics of micro diamond particle in aqueous system. Diam Abras Eng. 2011;31(3):15.

Tan CY. Fabrication of nickel, copper matrix composite coatings and their electrochemical behaviors. Changsha: Central South University; 2008. 4.

Hou SX, Gao H, Jia XM. Research on friction property of WS2 matrix solid lubricating coatings. Lubr Eng. 2013;4(38):82.

Ma WL, Lu JJ. Effect of sliding speed on surface modification and tribological behavior of copper-graphite composite. Tribol Lett. 2011;41(2):363.

Chen BM, Bi QL, Yang J, Xia Y, Hao J. Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites. Tribol Int. 2008;41(12):1145.

Kováčik J, Emmer Š, Bielek J, Keleši L. Effect of composition on friction coefficient of Cu-graphite composites. Wear. 2008;265(3–4):417.

Zhao YC, Xing HJ, Zhang ZW. The influence of lubricating phase MoS2 on Ni60A composite coatings frictional characteristics. China Ceram. 2008;44(12):29.

Wang XP, Xiao JK, Zhang L, Zhou KC. Effect of silver alloy particle size on friction and wear properties of Ag–MoS2 composites. Chin J Nonferrous Met. 2012;22(10):2811.

Lai DM, Tu JP, Zhang SC, Wang Q, Peng SM, He DN. Friction and wear properties of sputtered WS2/Ag nanocomposite films in different environments. Tribology. 2006;6(26):515.

Zheng C, Liu XB, Yang MS, Wang MD, Shi SH, Fu GY, Qi LH. High temperature self-lubricating wear-resistant NiCr–Cr3C2/30% WS2 (Ni–P) composite coating fabricated by laser cladding. Trans Mater Heat Treat. 2013;34(6):136.

Acknowledgements

This study was financially supported by International Science and Technology Cooperation Program of China (No. 2015DFR51090) and the Supporting Program of Gansu Province (No. 1604WKCA008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, S., Li, WS., He, L. et al. Tribological behavior of a Ni-WS2 composite coating across wide temperature ranges. Rare Met. 38, 1078–1085 (2019). https://doi.org/10.1007/s12598-018-1152-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1152-5