Abstract

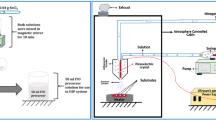

Tungsten nitride (WxN) thin films with good crystalline structure, high quality and relatively low resistivity were deposited by hot filament chemical vapor deposition (HFCVD) technique at different mixtures of N2 and Ar gases. Experimental data demonstrate that different N2 contents in gas mixture strongly affect microstructure, phase formation, texture morphology and resistivity of the WxN films. According to X-ray diffraction (XRD) patterns, the growth of tungsten nitride films promotes δ-WN phase for lower N2 contents in gas mixture. At higher N2 contents, a phase transition is observed in the tungsten nitride films. Both hexagonal δ-WN and cubic β-W2N phases coexist, and WN phase approximately disappears with N2 contents in the gas mixture increasing. Scanning electron microscope (SEM) images for deposited films at lower N2 contents in gas mixture indicate a definite dense columnar nanostructure. The electrical resistivity results exhibit a significant drop for the WxN thin films with N2 contents in the mixed gas increasing. The changes in N2 content in gas mixture are found to be responsible for variation in the film resistivity values. Thus, the deposited tungsten nitride thin film at higher N2 contents in gas mixture has noncolumnar microstructure and lower resistivity, which may be used as a superior diffusion barrier.

Similar content being viewed by others

References

Constable CP, Yarwood J, Munz WD. Raman microscopic studies of PVD hard coatings. Surf Coat Technol. 1999;116–119(2–3):155.

Becker SJ, Suh S, Wang Sh, Gordon RG. Highly conformal thin films of tungsten nitride prepared by atomic layer deposition from a novel precursor. Chem Mater. 2003;15(15):2969.

Marco JF, Gancedo JR, Auger MA, Sanchez O, Albella JM. Chemical stability of TiN, TiAlN and AlN layers in aggressive SO2 environments. Surf Interface Anal. 2005;37(12):1082.

Glaser A, Surnev S, Netzer FP, Fateh N, Fontalvo GA, Mitterer C. Oxidation of vanadium nitride and titanium nitride coatings. Surf Sci. 2007;601(4):1153.

Huang CF, Tsui BY, Lu CH. Thermal stability and electrical characteristics of tungsten nitride gates in metal–oxide–semiconductor devices. Jpn J Appl Phys. 2008;47(2):872.

Chakrapani V, Thangala J, Sunkara MK. WO3 and W2N nanowire arrays for photoelectrochemical hydrogen production. Hydrog Energy. 2009;34(22):9050.

Wang Z, Liu Z, Yang Z, Shingubara S. Characterization of sputtered tungsten nitride film and its application to Cu electroless plating. Microelectron Eng. 2008;85:395.

Lee CW, Kim YT. High temperature thermal stability of plasma-deposited tungsten nitride Schottky contacts to GaAs. Solid State Electron. 1995;38(3):679.

Lee CW, Kim YT, Min SK. Characteristics of plasma enhanced chemical vapor deposited tungsten nitride thin films. Appl Phys Lett. 1993;62(25):3312.

Shen YG, Mai YW, McBride WE, Zhang QC, McKenzie DR. Characteristics in sputtered tungsten nitride films. Thin Solid Films. 2000;37(1–2):257.

Moriwaki M, Yamada T, Harada Y, Fujii S, Fujii S, Yamanaka M, Shibata J, Mori Y. Improved metal gate process by simultaneous gate-oxide nitridation during W/WNx gate formation. Jpn J Appl Phys. 2000;39(4):2177.

Ko A, Han SB, Lee YW, Park KW. Template-free synthesis and characterization of mesoporous tungsten nitride nanoplates. Phys Chem Chem Phys. 2011;13(28):12705.

Levy F, Hones P, Schmid PE, Sanjines R, Diserns M, Wiemer C. Electronic states and mechanical properties in transition metal nitrides. Surf Coat Technol. 1999;120:284.

Chang KM, Yeh TH, Deng IC, Shih CW. Amorphous like chemical vapor deposited tungsten diffusion barrier for copper metallization and effects of nitrogen addition. J Appl Phys. 1997;82(3):1469.

Stach S, Garczyk Ż, Ţălu Ş, Solaymani S, Ghaderi A, Moradian R, Nezafat NB, Elahi SM, Gholamali H. Stereometric parameters of the Cu/Fe NPs thin films. J Phys Chem C. 2015;119(31):17887.

Ţălu Ş, Bramowicz M, Kulesza S, Shafiekhani A, Ghaderi A, Mashayekhi F, Solaymani S. Microstructure and tribological properties of FeNPs@a-C: H films by micromorphology analysis and fractal geometry. Ind Eng Chem Res. 2015;54(33):8212.

Chang KM, Yeh TH, Deng IC. Nitridation of fine grain chemical vapor deposited tungsten film as diffusion barrier for aluminum metallization. Appl Phys. 1997;81(8):3670.

Eizenberg M, Meyer F, Benhocine A, Bouchier D. Reactive-ion-beam-sputtered WNx films on silicon: growth mode and electrical properties. J Appl Phys. 1994;75(8):3900.

Yamamoto T, Kawate M, Hasegawa H, Suzuki T. Effects of nitrogen concentration on microstructures of WNx films synthesized by cathodic arc method. Surf Coat Technol. 2005;193(1–3):372.

Etaii GR, Hossinnejad MT, Ghoranneviss M, Habibi M, Shirazi M. Deposition of tungsten nitride on stainless steel substrates using plasma focus device. Nucl Instrum Methods Phys Res B. 2011;269(10):1058.

Bystrova S, Aarnink AAI, Holleman J, Wolters R. Atomic layer deposition of W1.5N barrier films for Cu metallization. J Electrochem Soc. 2005;152(7):522.

Lu JP, Hsu Y, Luttmer JD, Magel L, Tsai HL. A new process for depositing tungsten nitride thin films. J Electrochem Soc. 1998;145(2):21.

Tsai MH, Chiu HT, Chuang SH. Metal organic chemical vapor deposition of tungsten nitride for advanced metallization. Appl Phys Lett. 1996;68(10):1412.

Feugeas JN, Llonch EC, de Gonzalez CO, Galambos G. Nitrogen implantation of AISI 304 stainless steel with a coaxial plasma gun. J Appl Phys. 1988;64(5):2648.

Meunier C, Monteil C, Savall C, Palmino F, Weber J, Berjoan R, Durand J. RBS-ERDA, XPS and XRD characterizations of PECVD tungsten nitride films. Appl Surf Sci. 1998;125(3–4):313.

Shen YG, Mai YW. Structural studies of amorphous and crystallized tungsten nitride thin films by EFED, XRD and TEM. Appl Surf Sci. 2000;167(1–2):59.

Nakajima T, Watanabe K, Watanabe N. Preparation of tungsten nitride film by CVD method using WF6. J Electrochem Soc. 1987;134(12):3175.

Klaus JW, Ferro SJ, George SM. Atomic layer deposition of tungsten nitride films using sequential surface reactions. J Electrochem Soc. 2000;147(3):1175.

Uekubo M, Oku T, Nii K, Murakami M, Takahiro K, Yamaguchi S, Nakano T, Ohta T. WNx diffusion barriers between Si and Cu. Thin Solid Films. 1996;286(1–2):170.

Holloway K, Fryer PM, Cabral C, Harper JME, Bailey PJ, Kelleher KH. Tantalum as a diffusion barrier between copper and silicon: failure mechanism and effect of nitrogen additions. J Appl Phys. 1992;71(11):5433.

Wang MT, Lin YC, Chen MC. Barrier properties of very thin Ta and TaN layers against copper diffusion. J Electrochem Soc. 1998;17(1–3):2538.

Ajmera HM, Anderson T, Koller J, McElwee-White L, Norton DP. Deposition of WNxCy thin films for diffusion barrier application using the dimethylhydrazido (2−) tungsten complex (CH3CN)Cl4W(NNMe2). Thin Solid Films. 2009;517(21):6038.

Sadanand VD, Dupuiet JL, Gulari E. Filament-activated chemical vapour deposition of nitride thin films. Adv Mater Opt Electron. 1996;6(3):135.

Soto G, Cruz W, Castillón F, Díaz JA, Machorro R, Farías MH. Tungsten nitride films grown via pulsed laser deposition studied in situ by electron spectroscopies. Appl Surf Sci. 2003;214(1–4):58.

Vu QT, Pokela P, Garden CL, Kolawa E, Raud S, Nicolet MA. Thermal oxidation of reactively sputtered amorphous W(80)N(20) films. J Appl Phys. 1990;68(12):6420.

Jiang PC, Yen CK, Chen JS. Influence of thickness on the material characteristics of reactively sputtered W2N layer and electrical properties of W/W2N/SiO2/Si capacitors. J Alloy Compd. 2008;463(1–2):522.

Tang W, Xu KW, Wang P, Li X. Surface roughness and resistivity of Au film on Si-(111) substrate. Microelectron Eng. 2003;66(1–4):445.

Dirks AG, Wolters RAM, De Veirman AEM. Columnar microstructures in magnetron-sputtered refractory metal thin films of tungsten, molybdenum and W-Ti-(N). Thin Solid Films. 1992;208(2):181.

Jiang PC, Lai YS, Chen JS. Dependence of crystal structure and work function of WNx films on the nitrogen content. Appl Phys Lett. 2006;89(12):122107.

Ou KL, Wu WF, Chou CP, Chiou SY, Wu CC. Improved TaN barrier layer against Cu diffusion by formation of an amorphous layer using plasma treatment. J Vac Sci Technol B. 2002;20(5):2154.

Sun YM, Engbrecht ER, Bolom T, Cilino C, Sim JH, White JM, Ekerdt JG, Pfeifer K. Ultrathin tungsten nitride film growth on dielectric surface. Thin Solid Films. 2004;458(1–2):251.

Yamamoto T, Kawate M, Hasegawa H, Suzuki T. Effects of nitrogen concentration on microstructures of WNx films synthesized by cathodic arc method. Surf Coat Technol. 2005;93(1–3):372.

Boukhris L, Poitevin JM. Electrical resistivity, structure and composition of dc sputtered WNx films. Thin Solid Films. 1997;310(1–2):222.

Kim SD. Microstructural properties of plasma-enhanced chemical vapor deposited WNx films using WF6–H2–N2 precursor system. Curr Appl Phys. 2007;7(4):426.

Schlemminger W, Stark D. The influence of deposition temperature on the electrical resistance of thin Cu films. Surf Sci. 1987;189:1103.

Sadashivaiah PJ, Sankarappa T, Sujatha T, Santoshkumar M, Rawat R, Sarvanan P, Bhatnagar AK. Structural, magnetic and electrical properties of Fe/Cu/Fe films. Vacuum. 2010;85(3):466.

Chaverri D, Alejandro S, Castano V. Grain size and electrical resistivity measurements on aluminum polycrystalline thin films. Mater Lett. 1991;12(5):344.

Tseng WT, Wang YL, Niu J. Microstructure-related resistivity change after chemical–mechanical polish of Al and W thin films. Thin Solid Films. 2000;370(1–2):96.

Wen M, Meng QN, Yu WX, Zheng WT, Mao SX, Hua MJ. Growth, stress and hardness of reactively sputtered tungsten nitride thin films. Surf Coat Technol. 2010;205(7):1953.

Artamonov OM, Samarin SN, Williams JF. Electron screening and electron–electron scattering mechanisms. J Electron Spectrosc Relat Phenom. 2013;191:79.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asgary, S., Hantehzadeh, M.R., Ghoranneviss, M. et al. Structure, morphology and electrical resistance of WxN thin film synthesized by HFCVD method with various N2 contents. Rare Met. 39, 1440–1448 (2020). https://doi.org/10.1007/s12598-016-0696-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0696-5