Abstract

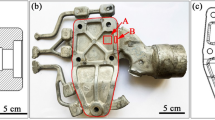

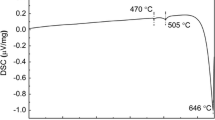

Alloying elements, present in the aluminum solid solution or the precipitates, influence the corrosion resistance of Al–Mg–Mn–Zn alloys. In this study, sensitizing treatment was applied to an Al–Mg–Mn–Zn alloy to modify the precipitation at the grain boundaries or in the grains. Transmission electron microscopy (TEM) and scanning electron microscope (SEM) were used to characterize various second-phase particles and determine their orientation relationship with the Al matrix. After sensitizing treatment, τ-phase (Mg32(Al, Zn)49) is observed to precipitate along the grain boundaries in a coarser size, producing a discontinuous grain boundary precipitate structure. In addition, Mn-rich particles are found to form with various shapes, such as global, plate and rhombus.

Similar content being viewed by others

References

Kaibyshev R, Musin F, Lesuer DR, Nieh TG. Superlastic behavior of an Al–Mg alloy at elevated temperatures. Mater Sci Eng A. 2003;342(1–2):169.

Katsas S, Nikolaou J, Papadimitriou G. Corrosion resistance of repair welded naval aluminium alloys. Mater Des. 2007;28(3):831.

Popović M, Romhanji E. Characterization of microstructural changes in an Al–6.8 wt% Mg alloy by electrical resistivity measurements. Mater Sci Eng A. 2008;492(1–2):460.

Tan L, Allen TR. Effect of thermomechanical treatment on the corrosion of AA5083. Corros Sci. 2010;52(2):548.

Davenport AL, Yuan Y, Ambat R, Connolly BJ, Strangwood M, Afseth A, Scamans G. Intergranular corrosion and stress corrosion cracking of sensitised AA5182. Mater Sci Forum. 2006;519–521:641.

Oguocha INA, Adigun OJ, Yannacopoulos S. Effect of sensitization heat treatment on properties of Al–Mg alloy AA5083-H116. J Mater Sci. 2008;43(12):4208.

Conserva M, Leoni M. Effect of thermal and thermo-mechanical processing on the properties of Al–Mg alloys. Metall Trans A. 1975;6A(189–195):189.

Yukawa H, Murata Y, Morinaga M, Takahashi Y, Yoshida H. Heterogeneous distributions of magnesium atoms near the precipitate in Al–Mg based alloys. Acta Metall Mater. 1995;43(2):68.

Carroll MC, Gouma PI, Mills MJ, Daehn GS, Dunbar BR. Effects of Zn additions on the grain boundary precipitation and corrosion of Al-5083. Scr Mater. 2000;42(4):335.

Meng CY, Zhang D, Cui H, Zhuang LZ, Zhang JS. Mechanical properties, intergranular corrosion behavior and microstructure of Zn modified Al–Mg alloys. J Alloy Compd. 2014;617:925.

Otsuka M, Horiuchi R. On the solution softening effect of zinc on aluminum–magnesium alloy at high temperatures. Trans JIM. 1973;14:213.

Goetz RL. Particle stimulated nucleation during dynamic recrystallization using a cellular automata model. Scr Mater. 2005;52(91):851.

Robson JD, Henry DT, Davis B. Particle effects on recrystallization in magnesium–manganese alloys: particle-stimulated nucleation. Acta Mater. 2009;57(9):2739.

Roven HJ, Liu M, Werenskiold JC. Dynamic precipitation during severe plastic deformation of an Al–Mg–Si aluminium alloy. Mater Sci Eng A. 2008;483–484(15):54.

Troeger LP, Starke EA Jr. Microstructural and mechanical characterization of a superplastic 6xxx aluminum alloy. Mater Sci Eng A. 2000;277(1):102.

Troger LP, Starke EA Jr. Particle-stimulated nucleation of recrystallization for grain-size control and superplasticity in an Al–Mg–Si–Cu alloy. Mater Sci Eng A. 2000;293(1–2):19.

Ye LY, Zhang XM, Du YX, Luo ZH. Particle-stimulated nucleation of recrystallization for grain-size control in 01420 Al–Li alloy. Mater Sci Forum. 2007;546–549:889.

Habiby F, Humphreys FJ. The effect of particle stimulated nucleation on the recrystallization texture of an Al–Si alloy. Scr Metall Mater. 1994;30(6):787.

Abae A, Bethencourt M, Botana FJ, Cano MJ, Marcos M. Localized alkaline corrosion of alloy AA5083 in neutral 3.5 % NaCl solution. Corros Sci. 2001;43(9):1657.

Jafarzadeh K, Shahrabi T, Hadavi SMM, Hosseini MG. Role of chloride ion and dissolved oxygen in electrochemical corrosion of AA5083-H321 aluminum–magnesium alloy in NaCl solutions under flow conditions. J Mater Sci Technol. 2007;23(5):623.

Arrabal R, Mingo B, Pardo A, Mohedano M, Matykina E, Rodríguez I. Pitting corrosion of rheocast A356 aluminium alloy in 3.5 wt% NaCl solution. Corros Sci. 2013;73:342.

Yasakau KA, Zheludkevich ML, Lamaka SV, Ferreira MGS. Role of intermetallic phases in localized corrosion of AA5083. Electrochim Acta. 2007;52(52):765.

Jiang H, Ye L, Zhang X, Gu G, Zhang P, Wu Y. Intermetallic phase evolution of 5059 aluminum alloy during homogenization. T Nonferr Metal Soc. 2013;23:3553.

Goswami R, Spanos G, Pao PS, Holtz RL. Precipitation behavior of the β phase in Al-5083. Mater Sci Eng A. 2010;527(4–5):1089.

Li J, Liu WC, Zhai T, Kenik EA. Comparison of recrystallization texture in cold-rolled continuous cast AA5083 and 5182 aluminum alloys. Scr Mater. 2005;52(3):163.

Vetrano JS, Bruemmer SM, Pawlowski LM, Robertson IM. Influence of the particle size on recrystallization and grain growth in Al–Mg–X alloys. Mater Sci Eng A. 1997;238(1):101.

Bennett TA, Petrov RH, Kestens LAI, Zhuang LZ, De Smet P. The effect of particle-stimulated nucleation on texture banding in an aluminium alloy. Scr Mater. 2010;63(5):461.

Gourdet S, Montheillet F. An experimental study of the recrystallization mechanism during hot deformation of aluminium. Mater Sci Eng A. 2000;283(1–2):274.

Lin CY, Lui TS, Chen LH. A study of microstructural stability of friction stir welded joints. In: Proceedings of Light Metals, TMS Annual Meeting. Orlando; 2012. 527.

Jamshidi AH, Serajzadeh S, Kokabi AH. Evolution of microstructures and mechanical properties in similar and dissimilar friction stir welding of AA5086 and AA6061. Mater Sci Eng A. 2011;528(28):8071.

Yamamoto N, Takahashi M, Ikeuchi K, Aritoshi M. Interfacial layer in friction-bonded joint of low carbon steel to Al–Mg alloy (AA5083) and its influence on bond strength. Mater Trans. 2004;45(2):296.

Zhou C, Yang X, Luan G. Investigation of microstructures and fatigue properties of friction stir welded Al–Mg alloy. Mater Chem Phys. 2006;98(2–3):285.

Chen DL, Chaturvedi MC. Effects of welding and weld heat-affected zone simulation on the microstructure and mechanical behavior of a 2195 aluminum–lithium alloy. Metall Mater Trans A. 2001;32(11):2729.

Kaibyshev R, Musin F, Avtokratova E, Motohashi Y. Deformation behavior of a modified 5083 aluminum alloy. Mater Sci Eng A. 2005;392(1–2):373.

Yuan Y. Localised corrosion and stress corrosion cracking of aluminum magnesium alloys. Britan: University of Birmingham; 2006. 34.

Searles JL, Gouma PI, Buchheit RG. Stress corrosion cracking of sensitized AA5083 (Al–4.5 Mg–1.0 Mn). Metall Mater Trans A. 2001;32(11):2859.

Birbilis N, Buchheit RG. Electrochemical characteristics of intermetallic phases in aluminum alloys. J Electrochem Soc. 2005;152(4):140.

Lyndon JA, Gupta RK, Gibson MA, Birbilis N. Electrochemical behaviour of the β-phase intermetallic (Mg2Al3) as a function of pH as relevant to corrosion of aluminium–magnesium alloys. Corros Sci. 2013;70:290.

Zhan G. Effect of stabilizing annealing temperature and processing on microstructure and properties of 383 aluminum alloy. Changsha: Central South University; 2013. 45.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51301017) and the Common Construction Project from Beijing Municipal Commission of Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, CY., Zhang, D., Liu, PP. et al. Microstructure characterization in a sensitized Al–Mg–Mn–Zn alloy. Rare Met. 37, 129–135 (2018). https://doi.org/10.1007/s12598-015-0665-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0665-4