Abstract

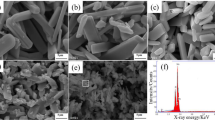

At three critical temperatures which were obtained by thermo-gravimetry-differential thermal analysis–differential scanning calorimetry (TG/DTG/DSC) curves of lanthanum nitrate crystal, the air thermal decomposition experiments and solid–liquid spray doping simulation procedures of lanthanum nitrate crystal were carried out, and their products were analyzed by X-ray diffraction (XRD). Meanwhile, the spray doping processing of MoO2–50 wt% La(NO3)3 composite powder was undergone with lanthanum nitrate solution as the dopant, and doped MoO2 powder was analyzed by XRD. The results demonstrate that during the traditional solid–liquid spray doping processing, lanthanum nitrate, in the form of either crystal or aqueous solution, would be converted into La(NO3)3·4H2O by the dehydration reaction, rather than be decomposed to La2O3 and NO or NO2. Therefore, it is inferred that the oxynitride gas produced from the process is attributed to the decomposition of residual HNO3 in lanthanum nitrate crystal. The source of HNO3 is supported by the chemical composition of lanthanum nitrate crystal.

Similar content being viewed by others

References

Mrotzek T, Hoffmann A, Martin U. Hardening mechanisms and recrystallization behavior of several molybdenum alloys. Int J Refract Metal Hard Mater. 2006;24(4):298.

Shields JA Jr, Rozak GA. Electronic applications for P/M molybdenum. Int J Powder Metall. 2005;41(2):21.

Li CX, Luo YQ, Ren RC, Cheng Q, Man D. Enriching metal elements of carbonaceous molybdenum-nickel ore before leaching. Chin J Rare Met. 2013;37(2):289.

Geller CB, Smith RW, Hack JE, Saxe P, Wimmer E. A computational search for ductilizing additives to Mo. Scripta Mater. 2005;52(3):205.

Miller MK, Kenik EA, Mousa MS, Russell KF, Bryhan AJ. Improvement in the ductility of molybdenum alloys due to grain boundary segregation. Scripta Mater. 2002;46(4):299.

Shi HJ, Niu LS, Korn C, Pluvinage G. High temperature fatigue behaviour of TZM molybdenum alloy under mechanical and thermomechanical cyclic loads. J Nucl Mater. 2000;278(2–3):328.

Leichtfried G, Schneibel JH, Heilmaier M. Ductility and impact resistance of powder-metallurgical molybdenum-rhenium alloys. Metall Mater Trans A. 2006;37(10):2955.

Garin JL, Mannheim RL. Manufacturing of Mo-25Re and Mo-50Re alloys by means of powder sintering at medium temperature. Mater Manuf Processes. 1998;13(5):731.

Mohammed JS. A Study of High Temperature reactions in oxide-dispersion-strengthened molybdenum at reduced oxygen partial pressures. Georgia: Georgia Institute of Technology; 2004. 5.

Zhang GJ, Sun YJ, Zuo C, Wei JF, Sun J. Microstructure and mechanical properties of multi-components rare earth oxide-doped molybdenum alloys. Mater Sci Eng A. 2008;483:350.

Iorio LE, Bewlay BP, Larsen M. Analysis of ASK- and lanthana-doped molybdenum wire. Int J Refract Metal Hard Mater. 2006;24(4):306.

Zhang JX, Liu L, Zhou ML, Hu YC, Zuo TY. Fracture toughness of sintered Mo-La2O3 alloy and the toughening mechanism. Int J Refract Metal Hard Mater. 1999;17(6):405.

Zhang GJ, Liu G, Sun YJ, Jiang F, Wang L, Wang RH, Sun J. Microstructure and strengthening mechanisms of molybdenum alloy wires doped with lanthanum oxide particles. Int J Refract Metal Hard Mater. 2009;27(1):173.

Feng PF, Fu JB, Liu RZ, Zhao H, Yang QL, Sun J. Analysis on time sequence characteristics of occurrence status of lanthanum in Mo alloy wires. Chin J Rare Met. 2011;35(4):486.

Feng P F. Studies on improvement of strength and toughness of molybdenum with rare earth oxides/MoSi2 particles. Xi’an: Xi’an Jiaotong University; 2011. 47.

Gao SL, Yang ZP, Yang BY. Study on heat decomposition mechanism of La(NO3)3·6H2O and La(NO3)3·4H2O. J Northwest Inst Archit Eng. 1988;2:65.

Moini A, Subramanian MA, Clearfield A, Disalvo FJ, Mccarroll WH. Structure and properties of La2Mo2O7: a quasi-two-dimensional metallic oxide with strong Mo-Mo bonds. J Solid State Chem. 1987;66:136.

Acknowledgments

This study was financially supported by the National Science and Technology Support Program of China (No. 2012BAE06B02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, PF., Yang, QL., Dang, XM. et al. Reaction mechanism of lanthanum nitrate-doped Mo–La material during solid–liquid spray doping processing. Rare Met. 34, 814–817 (2015). https://doi.org/10.1007/s12598-014-0422-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0422-0