Abstract

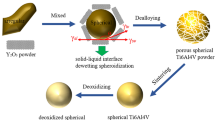

Owing to its high production costs, complexity of equipment, and difficulty in controlling parameters, spherical or subglobose tungsten powder preparation method cannot meet the demand of industrial production. Tungstic oxide powder was treated by particle composite system and its effects were studied. Morphologies of particles were investigated by scanning electron microscopy (SEM). Particle size analysis was carried out and the related mechanism was discussed. The results show that the processing effect is best when the rotational speed is set at 4,000 r·min−1 for 15 min: the powder particles become nearly spherical and their sharp edge angles are rounded off and reshaped. When the processing time is 60 min, the powders smash to pieces because of too much energy inputting. So the test results, such as grain size distribution, can be explained well. Nearly spherical tungsten powder is obtained after reduction at 780 °C for 2 h and its flow ability is significantly improved.

Similar content being viewed by others

References

Peng ZH, Li HG. Behaviours of local priority reoxidation of tungsten powder—a study. Metall Eng. 1999;19(2):61.

White GD, Gurwell WE. Freeze dried tungsten heavy alloys. Adv Powder Metall. 1989;1:355.

Smith RW, Kim M, Kappor D. Structure and properties of spray formed tungsten base composite. Adv Part Mater Process. Princeton; 1997. 219.

Luo LM, Lu ZL, Li H, Luo GN, Zan X, Wu YC. Current status and development trend on rare earth modified tungsten alloys. Chin J Rare Met. 2013;37(6):993.

Qiao JC, Xi ZP, Tang HP, Zhu JL, Wang JY, Ao QB. Current status of metal porous materials by powder metallurgy technology. Rare Met Mater Eng. 2008;37(11):2054.

Zhou HB, Jin S, Zhang Y, Lu GH. First-principles study of carbon effects in a tungsten grain boundary: site preference, segregation and strengthening. Sci China-Phys Mech Astron. 2011;54(12):2164.

Lei CP, Tang JC, Cai DY, Wu AH. Reduction-carburization medium-size tungsten carbide powder. Chin J Rare Met. 2013;37(3):365.

Liu KM, Liao JC, Zhang ZD. A new technology of preparation spherical tungsten powder. Rare Met Mater Eng. 1987;4:26.

Guo SQ, Ge CC, Feng YB, Zhou ZJ, Zhou ZJ. Research on low-cost plasma spheroidization technology for spherical tungsten powder used in thermal spraying. Powder Metall Ind. 2010;20(3):1.

Sheng YW, Hao JJ, Guo ZM, Shao HP, Huang H. Preparation of spherical tungsten powder by RF induction plasma. Rare Met Mater Eng. 2011;40(11):2033.

Peng ZH, Li HG. Research on the effects of oxidation rate with re-oxidation process parameters of tungsten powder. Rare Metal Cem Carbides. 1993;3(114):14.

Fu XM. Submicron spherical tungsten powder prepared with ammonium paratungstate through the circulatory oxidization-reduction method. Rare Met Mater Eng. 2010;39(S1):468.

Liu XB, Jia CC, Chen CH, Gai GS. Fabrication of nano-Al2O3/Cu composite with powder treated by spherical process. J Iron Steel Res. 2007;14(1):94.

Hao XY, Gai GS, Yang YF, Nan CW, Lai MB. PCS system and application. Nonferrous Min Metall. 2005;21(S1):142.

Pfeffer R, Dave RN, Wei DG, Ramlakhan M. Synthesis of engineered particulates with tailored properties using dry particle coating. Powder Technol. 2001;117(1):40.

Hao XY, Gai GS, Zou X, Wu YX, Zhang YH, Emmanuelle R. Shape modification of HDH Ti powder and its mechanism analysis. Rare Met Mater Eng. 2009;38(S3):264.

Liu Y, Tang JC, Lei CP, Ye N, Zhuo HO. Hydrogen reducing process and mechanism of tungsten oxide. Powder Metall Ind. 2012;22(04):26.

Wang G, Li HH, Huang ZW, Chen MH, Wang QK, Zhong WL. Comparison of ultrafine tungsten powder produced by hydrogen reduction of blue tungsten oxide and violet tungsten oxide. Rare Met Mater Eng. 2009;38(S1):548.

Xie ZH, Chen SM, Wang WH, Zhang QH, Zhao HT, Liu B. On the preparation technology of spherical tungsten powder. China Tungsten Ind. 2009;24(4):40.

Acknowledgments

This study was financially supported by the International Science and Technology Cooperation Program of China (No. 2010DFR50360).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, CC., Jia, CC., Gao, P. et al. Spherical modification of tungsten oxide powder and its mechanism analysis. Rare Met. 34, 183–188 (2015). https://doi.org/10.1007/s12598-014-0370-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0370-8