Abstract

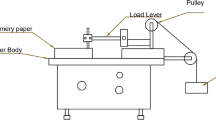

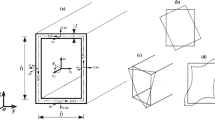

In this study, mode II(sliding) adhesive strengths of tapered double-cantilever beam (TDCB) specimens of aluminum foams bonded with adhesives were evaluated by finite element analysis. Models were fabricated for testing, and their length and thickness were 200 mm and 25 mm, respectively, while the angles between the adhesive layers and the horizontal direction for models (a), (b), and (c) were 8°, 10°, and 12°, respectively. The joint adhesive method was applied to the models that were made of Al-SAF40, aluminum foam. To generate the crack in shear direction, one end of the loaded block was restrained with a frictionless support while the other end of the loaded block was set to be displaced at the rate of 10 mm/min in the adhesive layer. The analysis and comparison result between the 3 different models revealed that the larger the tilt angle θ of sliding mode was, the larger the maximum load became, while the time to reach the maximum load and the time taken until the load disappeared were shorter as the value increased in the displacement-force reaction curve. This study can be applied to real structures with tapered contact surfaces by analyzing fracture behaviors and characteristics of composite materials such as aluminum foams bonded with adhesives.

Similar content being viewed by others

References

Paul, A. and Ramamurty, U., “Strain Rate Sensitivity of a Closed-Cell Aluminum Foam,” Materials Science and Engineering: A, vol. 281, no. 1, pp. 1–7, 2000.

Batra, R. C. and Peng, Z., “Development of Shear Bands in Dynamic Plane Strain Compression of Depleted Uranium and Tungsten Blocks,” International Journal of Impact Engineering, vol. 16, no. 3, pp. 375–395, 1995.

Han, M. S., Choi, H. K., Cho, J. U., and Cho, C. D., “Experimental Study on the Fatigue Crack Propagation Behavior of DCB Specimen with Aluminum Foam,” Int. J. Precis. Eng. Manuf., vol. 14, no. 8, pp. 1395–1399, 2013.

Zhang, Y. J. and Yang, C. S., “FEM Analyses for Influences of Stress-Chemical Solution on THM Coupling in Dual-Porosity Rock Mass,” Journal of Central South University, Vol. 19, pp. 1138–1147, 2012.

Öchsner, A., Stasiek, M., Mishuris, G., and Grácio, J., “A New Evaluation Procedure for the Butt-Joint Test of Adhesive Technology: Determination of the Complete Set of Linear Elastic Constants,” International Journal of Adhesion and Adhesives, vol. 27, no. 8, pp. 703–711, 2007.

Adams, R. D. and Harris, J. A., “A Critical Assessment of the Block Impact Test for Measuring the Impact Strength of Adhesive Bonds,” International Journal of Adhesion and Adhesives, vol. 16, no. 2, pp. 61–71, 1996.

Shokrieh, M., Heidari-Rarani, M., and Rahimi, S., “Influence of Curved Delamination Front on Toughness of Multidirectional DCB Specimens,” Composite Structures, vol. 94, no. 4, pp. 1359–1365, 2012.

Blackman, B. R. K., Dear, J. P., Kinloch, A. J., MacGillivray, H., Wang, Y., et al., “The Failure of Fibre Composites and Adhesively Bonded Fibre Composites under High Rates of Test,” Journal of Materials Science, vol. 31, no. 17, pp. 4467–4477, 1996.

Hojo, M., Ando, T., Tanaka, M., Adachi, T., Ochiai, S., and Endo, Y., “Modes I and II Interlaminar Fracture Toughness and Fatigue Delamination of CF/Epoxy Laminates with Self-Same Epoxy Interleaf,” International Journal of Fatigue, vol. 28, no. 10, pp. 1154–1165, 2006.

Blackman, B. R. K., Hadavinia, H., Kinloch, A. J., Paraschi, M. and Williams, J. G., “The Calculation of Adhesive Fracture Energies in Mode I: Revisiting the Tapered Double Cantilever Beam (TDCB) Test,” Engineering Fracture Mechanics Vol. 70, No. 2, pp. 233–248, 2003.

BS 7991:2001, “Determination of the Mode I Adhesive Fracture Energy, GIC, of Structural Adhesives using the Double Cantilever Beam (DCB) and Tapered Double Cantilever Beam (TDCB) Specimens,” 2001.

Nakai, Y. and Hiwa, C., “Effects of Loading Frequency and Environment on Delamination Fatigue Crack Growth of CFRP,” International Journal of Fatigue, vol. 24, no. 2, pp. 161–170, 2002.

Ohno, N., Okumura, D., and Niikawa, T., “Long-Wave Buckling of Elastic Square Honeycombs Subject to In-Plane Biaxial Compression,” International Journal of Mechanical Sciences, vol. 46, no. 11, pp. 1697–1713, 2004.

Aymerich, F., Onnis, R., and Priolo, P., “Analysis of the Effect of Stitching on the Fatigue Strength of Single-Lap Composite Joints,” Composites Science and Technology, vol. 66, no. 2, pp. 166–175, 2006.

Michailidis, N., Stergioudi, F., Omar, H., and Tsipas, D., “An Imagebased Reconstruction of the 3D Geometry of an Al Open-Cell Foam and FEM Modeling of the Material Response,” Mechanics of Materials, vol. 42, no. 2, pp. 142–147, 2010.

Kim, S. S., Han, M. S., Cho, J. U., and Cho, C. D., “Study on the Fatigue Experiment of TDCB Aluminum Foam Specimen Bonded with Adhesive,” Int. J. Precis. Eng. Manuf., vol. 14, no. 10, pp. 1791–1795, 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, H.P., Cho, J.U. Experiment and analysis verification of shearing fracture characteristic of tapered double cantilever beam with aluminum foam. Int. J. Precis. Eng. Manuf. 16, 1661–1666 (2015). https://doi.org/10.1007/s12541-015-0218-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0218-7