Abstract

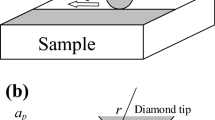

Effects of surface mechanical grinding treatment on the structure evolution and grain refinements of gradient structured surface layer on Inconel 625 have been studied. The results showed that a 600 μm thick gradient nanotwinned (GNT) structure layer could be successfully constructed in the superficial layer of the alloy by adjusting the process parameters. The TEM characterization revealed that a gradient change from nano-grain and nanotwinned to dislocation structure was formed in the alloy structure, and the grain size of the outermost layer of the alloy could be refined to 18 nm, with a thickness of up to 30 μm and a surface hardness of 7.4 GPa. In addition, with an increase in the layer depth, twinning played a major role in the refinement. Firstly, a high-density twin/matrix lamellar structure was formed in the microstructure at high strain rates during the process of plastic-induced grain refinement, and the original coarse grains were refined. During further deformation, due to the increasing difficulty of work hardening and the reactions between dislocations and twin boundaries, the lamellar structure was sheared and broken into equiaxed nanocrystals. Finally, the nanocrystals were further refined to a smaller size through twinning. During this process, twinning is more likely to occur for a grain size of 71–80 nm. These findings shed light on the basic principle of GNT construction, especially the twinning induced grain refinement mechanism under different grain sizes.

Graphical Abstract

Similar content being viewed by others

Data Availability

The authors declare that the data supporting the findings of this study are available within the paper.

References

X.Y. Li, K. Lu, Nat. Mater. 16, 700–701 (2017)

L. Yang, X.Y. Li, K. Lu, Acta Metall. 53, 1413–1417 (2017)

X.Y. Li, K. Lu, Science 364, 733–734 (2019)

L. Lu, X. Chen, X. Huang, K. Lu, Science 323, 607–610 (2009)

O. Bouaziz, S. Allain, C. Scott, Scr. Mater. 58, 484–487 (2008)

B.C. De Cooman, Y. Estrin, S.K. Kim, Acta Mater. 142, 283–362 (2018)

K.I. Sugimoto, M. Kobayashi, S.-I. Hashimoto, Metall. Trans. A 23, 3085–3091 (1992)

R.J. Ji, Z.L. Yang, H. Jin, Y.H. Liu, H.Y. Wang, Q. Zheng, W.H. Cheng, B.P. Cai, X.P. Li, Surf. Coat. Technol. 375, 292–302 (2019)

E. Maleki, O. Unal, M. Guagliano, S. Bagherifard, Met. Mater. Int. 28, 112–131 (2022)

B. Song, H.Z. Zhao, L.J. Chai, N. Guo, H.C. Pan, H.B. Chen, R.L. Xin, Met. Mater. Int. 22, 887–896 (2016)

N.R. Tao, Z.B. Wang, W.P. Tong, M.L. Sui, J. Lu, K. Lu, Acta Mater. 50, 4603–4616 (2002)

K. Wang, N.R. Tao, G. Liu, J. Lu, K. Lu, Acta Mater. 54, 5281–5291 (2006)

H.W. Huang, Z.B. Wang, J. Lu, K. Lu, Acta Mater. 87, 150–160 (2015)

W.L. Li, N.R. Tao, K. Lu, Scr. Mater. 59, 546–549 (2008)

T.H. Fang, N.R. Tao, K. Lu, Science 331, 1587–1590 (2011)

X.C. Liu, H.W. Zhang, K. Lu, Acta Mater. 96, 24–36 (2015)

B.S. Xu, Nano Surface Engineering (Chemical Industry Press, Beijing, 2004)

Y.B. Gao, Y.T. Ding, J.J. Chen, J.Y. Xu, X.M. Wang, Mater. Sci. Eng. A 767, 138361 (2019)

R. Pippan, S. Scheriau, A. Taylor, M. Hafok, A. Hohenwarter, A. Bachmaier, Annu. Rev. Mater. Res. 40, 319–343 (2010)

R. Pippan, F. Wetscher, M. Hafok, A. Vorhauer, I. Sabirov, Adv. Eng. Mater. 8, 1046–1056 (2006)

X.C. Liu, H.W. Zhang, K. Lu, Science 342, 337–340 (2013)

N.R. Tao, X.L. Wu, M.L. Sui, J. Lu, K. Lu, J. Mater. Res. 19, 1623–1629 (2004)

H.W. Zhang, Z.K. Hei, G. Liu, J. Lu, K. Lu, Acta Mater. 51, 1871–1881 (2003)

R.P. Singh, R.D. Doherty, Metall. Trans. A 23, 307–319 (1992)

F.D. Torre, R. Lapovok, J. Sandlin, P.F. Thomson, C.H.J. Davies, E.V. Pereloma, Acta Mater. 52, 4819–4832 (2004)

N. Hansen, X. Huang, Acta Mater. 46, 1827–1836 (1998)

X.Z. Liao, Y.H. Zhao, Y.T. Zhu, R.Z. Valiev, D.V. Gunderov, J. Appl. Phys. 96, 636–640 (2004)

Y.S. Li, N.R. Tao, K. Lu, Acta Mater. 56, 230–241 (2008)

B.E. Warren, X-Ray Diffraction (Addison-Wesley, Reading, 1969)

Y.H. Zhao, H.W. Sheng, K. Lu, Acta Mater. 49, 365–375 (2001)

G.K. Williamson, R.E. Smallman III., Philos. Mag. 1, 34–46 (1956)

J.A. Venables, Philos. Mag. 6, 379–396 (1961)

S. Ni, Y.B. Wang, X.Z. Liao, R.B. Figueiredo, H.Q. Li, S.P. Ringer, T.G. Langdon, Y.T. Zhu, Acta Mater. 60, 3181–3189 (2012)

Z. Feng, X. Luo, Y. Chen, N. Chen, L. Zhang, G. Wu, X. Huang, Mater. Sci. Eng. A 771, 138486 (2020)

K.P.D. Lagerlof, J. Castaing, P. Pirouz, A.H. Heuer, Philos. Mag. A 82, 2841–2854 (2002)

J.P. Hirth, J. Lothe, Theory of Dislocations, 2nd edn. (Krieger Publishing, Malabar, 1992)

Y.T. Zhu, X.Z. Liao, X.L. Wu, Prog. Mater. Sci. 57, 1–62 (2012)

Acknowledgements

We would like to thank Professor Xiuyan Li, Baobing Zhang and Chen Liang for data analysis and experimental processing. In addition, this work was financially supported by the National Key Research and Development Program of China (Grant No. 2017YFA07007003) and the National Natural Science Foundation of China (Grant No. 51661019), the program for Major Projects of Science and Technology in Gansu Province (Grant No. 145RTSA004), and the Hongliu first-class discipline construction plan of Lanzhou University of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, Y., Ding, Y., Gao, Y. et al. Gradient Nanotwinned Structure and Its Formation Mechanism in Inconel 625 Alloy Produced by Surface Mechanical Grinding Treatment. Met. Mater. Int. 29, 1454–1468 (2023). https://doi.org/10.1007/s12540-022-01297-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01297-3