Abstract

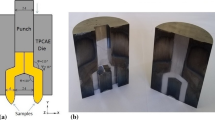

This article proposes a new severe plastic technique named Multi-angular twist channel extrusion (MATE) to process the AA2024 aluminium alloy in a single pass. This method was devised to impose a large strain in a single pass with better strain homogeneity and lower punch load. To understand the deformation behavior of the AA2024 alloy during the MATE process, hardness, strain behavior, and microstructure analysis were performed in each shear zones. From the finite element analysis, an average effective strain of 2.78 was achieved with good strain homogeneity. The tensile strength and hardness of AA2024 alloy were increased by 80.5 and 91.27%, respectively. The electron back scatter diffraction analysis reveals that the average grain size was 1.8 µm and a strong texture was developed in the processed AA2024 alloy. The XRD analysis reveals a high amount of dislocation density (3.18 × 1014 M−2) in the extruded metal. Enhancement in the mechanical properties was attributed to grain refinement and strain hardening. Continuous dynamic recrystallization has occurred due to the formation of fine grains and the conversion of low-angle grain boundaries to high-angle grain boundaries during the MATE process.

Graphical Abstract

Similar content being viewed by others

References

Y. Estrin, A. Vinogradov, Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61(3), 782–817 (2013)

M. Król, T. Tański, P. Snopiński, B. Tomiczek, Structure and properties of aluminium–magnesium casting alloys after heat treatment. J. Therm. Anal. Calorim. 127(1), 299–308 (2017)

K. Edalati, S. Lee, Z. Horita, Continuous high-pressure torsion using wires. J. Mater. Sci. 47(1), 473–478 (2012)

A. Hohenwarter, Incremental high pressure torsion as a novel severe plastic deformation process: processing features and application to copper. Mater. Sci. Eng., A 626, 80–85 (2015)

M. Jahedi, M.H. Paydar, S. Zheng, I.J. Beyerlein, M. Knezevic, Texture evolution and enhanced grain refinement under high-pressure-double-torsion. Mater. Sci. Eng., A 611, 29–36 (2014)

G. Gurău, C. Gurău, O. Potecaşu, P. Alexandru, L.G. Bujoreanu, Novel high-speed high pressure torsion technology for obtaining Fe-Mn-Si-Cr shape memory alloy active elements. J. Mater. Eng. Perform. 23(7), 2396–2402 (2014)

B. Mani, M. Jahedi, M.H. Paydar, A modification on ECAP process by incorporating torsional deformation. Mater. Sci. Eng., A 528(12), 4159–4165 (2011)

M.H. Paydar, M. Reihanian, E. Bagherpour, M. Sharifzadeh, M. Zarinejad, T.A. Dean, Equal channel angular pressing–forward extrusion (ECAP–FE) consolidation of Al particles. Mater. Des. 30(3), 429–432 (2009)

S. Sepahi-Boroujeni, F. Fereshteh-Saniee, Expansion equal channel angular extrusion, as a novel severe plastic deformation technique. J. Mater. Sci. 50(11), 3908–3919 (2015)

A. Fadaei, F. Farahafshan, S. Sepahi-Boroujeni, Spiral equal channel angular extrusion (Sp-ECAE) as a modified ECAE process. Mater. Des. 113, 361–368 (2017)

M. Ensafi, G. Faraji, H. Abdolvand, Cyclic extrusion compression angular pressing (CECAP) as a novel severe plastic deformation method for producing bulk ultrafine grained metals. Mater. Lett. 197, 12–16 (2017)

G.R. Ebrahimi, A. Barghamadi, H.R. Ezatpour, A. Amiri, A novel single pass severe plastic deformation method using combination of planar twist extrusion and conventional extrusion. J. Manuf. Process. 47, 427–436 (2019)

H. Ataei, M. Shahbaz, H.S. Kim, N. Pardis, Finite element Analysis of severe plastic deformation by rectangular vortex extrusion. Met. Mater. Int. 27, 676–682 (2021)

S.M. Alavizadeh, K. Abrinia, A. Parvizi, Twisted multi channel angular pressing (TMCAP) as a novel severe plastic deformation method. Met. Mater. Int. 26(2), 260–271 (2020)

D.M. Fouad, A. Moataz, W.H. El-Garaihy, H.G. Salem, Numerical and experimental analysis of multi-channel spiral twist extrusion processing of AA5083. Mater. Sci. Eng., A 764, 138216 (2019)

R. Kocich, A. Macháčková, L. Kunčická, Twist channel multi-angular pressing (TCMAP) as a new SPD process: numerical and experimental study. Mater. Sci. Eng., A 612, 445–455 (2014)

R. Kocich, L. Kunčická, M. Mihola, K. Skotnicová, Numerical and experimental analysis of twist channel angular pressing (TCAP) as a SPD process. Mater. Sci. Eng., A 563, 86–94 (2013)

M. Nouri, H.M. Semnani, E. Emadoddin, H.S. Kim, Investigation of direct extrusion channel effects on twist extrusion using experimental and finite element analysis. Measurement 127, 115–123 (2018)

U.M. Iqbal, S. Muralidharan, Optimization of die design parameters and experimental validation on twist channel angular pressing process of AA6061-T6 aluminium alloy. Mater. Res. Express 6(8), 0865f2 (2019)

Y. Beygelzimer, R. Kulagin, Y. Estrin, L.S. Toth, H.S. Kim, M.I. Latypov, Twist extrusion as a potent tool for obtaining advanced engineering materials: a review. Adv. Eng. Mater. 19(8), 1600873 (2017)

Y. Iwahashi, Z. Horita, M. Nemoto, J. Wang, T.G. Langdon, Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scripta materialia 35(2), 143 (1996)

ASM Handbook Committee, Properties and Selection: Non-ferrous Alloys and Special- Purpose Materials, vol. 2 (ASM International, Almere, 1990)

V.P. Basavaraj, U. Chakkingal, T.P. Kumar, Study of channel angle influence on material flow and strain inhomogeneity in equal channel angular pressing using 3D finite element simulation. J. Mater. Process. Technol. 209(1), 89–95 (2009)

Y. Beygelzimer, A. Reshetov, S. Synkov, O. Prokofeva, R. Kulagin, Kinematics of metal flow during twist extrusion investigated with a new experimental method. J. Mater. Process. Technol 209(7), 3650–3656 (2009)

R. Kocich, J. Fiala, I. Szurman, A. Macháčková, M. Mihola, Twist-channel angular pressing: effect of the strain path on grain refinement and mechanical properties of copper. J. Mater. Sci. 46(24), 7865–7876 (2011)

S. Xu, G. Zhao, X. Ma, G. Ren, Finite element analysis and optimization of equal channel angular pressing for producing ultra-fine grained materials. J. Mater. Process. Technol. 184(1–3), 209–216 (2007)

U.M. Iqbal, V.S. Kumar, S. Gopalakannan, Application of response surface methodology in optimizing the process parameters of twist extrusion process for AA6061-T6 aluminum alloy. Measurement 94, 126–138 (2016)

H. Bisadi, M.R. Mohamadi, H. Miyanaji, M. Abdoli, A modification on ECAP process by incorporating twist channel. J. Mater. Eng. Perform. 22(3), 875–881 (2013)

X.X. Wang, H.E. Min, Z.H.U. Zhen, K.M. Xue, L.I. Ping, Influence of twist extrusion process on consolidation of pure aluminum powder in tubes by equal channel angular pressing and torsion. Trans. Nonferr. Metals Soc. China 25(7), 2122–2129 (2015)

M. Shamsborhan, A. Shokuhfar, A planar twist channel angular extrusion (PTCAE) as a novel severe plastic deformation method based on equal channel angular extrusion (ECAE) method. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 228(12), 2246–2250 (2014)

F. Rahimi, A.R. Eivani, M. Kiani, Effect of die design parameters on the deformation behavior in pure shear extrusion. Mater. Des. 83, 144–153 (2015)

X.H. Fan, D. Tang, W.L. Fang, D.Y. Li, Y.H. Peng, Microstructure development and texture evolution of aluminum multi-port extrusion tube during the porthole die extrusion. Mater. Charact. 118, 468–480 (2016)

M. Tilli, A. Haapalinna, in Handbook of Silicon Based MEMS Materials and Technologies, 2nd edn., ed. by M. Tilli, T. Motooka, V.-M. Airaksinen, S. Franssila, M. Paulasto-Kröckel, V. Lindroos (William Andrew, Norwich, 2015), pp. 3–7

F. Montheillet, in Moving Interfaces in Crystalline Solids, ed. by F.D. Fischer. CISM International Centre for Mechanical Sciences, vol. 453 (Springer, Vienna, 2004), pp. 203–256

Y. Huang, F.J. Humphreys, Measurements of grain boundary mobility during recrystallization of a single-phase aluminium alloy. Acta Mater. 47(7), 2259–2268 (1999)

R. Kocich, L. Kunčická, P. Král, A. Macháčková, Sub-structure and mechanical properties of twist channel angular pressed aluminium. Mater. Charact. 119, 75–83 (2016)

K. Huang, R.E. Logé, A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 111, 548–574 (2016)

K.S.V.B.R. Krishna, S. Vigneshwaran, K.C. Sekhar, S.S. Akella, K. Sivaprasad, R. Narayanasamy, K. Venkateswarlu, Mechanical behavior and void coalescence analysis of cryo-rolled AA8090 alloy. Int. J. Adv. Manufact. Technol. 93(1), 253–259 (2017)

M.H. Goodarzy, H. Arabi, M.A. Boutorabi, S.H. Seyedein, S.H. Najafabadi, The effects of room temperature ECAP and subsequent aging on mechanical properties of 2024 Al alloy. J. Alloy. Compd. 585, 753–759 (2014)

G.E. Dieter, Mechanical Metallurgy, 3rd edn. (McGraw-Hill, London, 1986)

Acknowledgements

The authors are grateful to the DST-SERB, New Delhi, India for their grant support and the department of mechanical engineering of SRM institute of Science and Technology for providing the facilities to carry out the research.

Funding

This research is supported by the department of Science and Technology-Science & Engineering Research Board (DST-SERB), New Delhi, India, under the Core Research Grant (CRG), Grant No. [CRG/2021/000499].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muralidharan, S., Iqbal, U.M. Analysis of Multi-angular Twist Channel Extrusion Technique for Processing AA2024 Aluminium Alloy. Met. Mater. Int. 29, 515–535 (2023). https://doi.org/10.1007/s12540-022-01221-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01221-9