Abstract

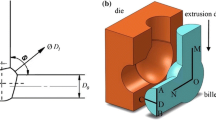

In this study, a method that combines the equal channel angular pressing (ECAP) and twist extrusion (TE) techniques has been introduced as a severe plastic deformation process and investigated by means of the three-dimensional finite element analysis. Owing to the form of the mold which is used in this technique, it can be called the symmetrical channels angular pressing (SCAP) method. This method resembles the more common ECAP process for samples with rectangular cross sections, with the difference that, in this method, the entrance and exit channels at the intersecting corner of the mold also have a twist about their longitudinal axis (as in the TE technique). In this study, to show the characteristics of the SCAP method and to compare it with the ECAP technique, the former method has been simulated by the ABAQUS/Explicit software. Also, to validate the obtained results, the SCAP and ECAP methods were practically applied on samples made of pure commercial aluminum (AA1050). To get the strain distribution along the longitudinal and transverse directions of the samples, Vickers hardness was measured on these samples. The results obtained from these hardness measurements indicate that after one pass, the SCAP method can achieve a higher amount of hardness, compared with the ECAP technique. Moreover, the strain distributions obtained from the simulation and from the samples demonstrate that the SCAP method produces a more homogeneous distribution of strain in the workpieces.

Similar content being viewed by others

References

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater Sci., 2006, 51, p 881–981

E.A. El-Danaf, M.S. Soliman, A.A. Almajid, and M.M. El-Rayes, Enhancement of Mechanical Properties and Grain Size Refinement of Commercial Purity Aluminum 1050 Processed by ECAP, Mater. Sci. Eng. A, 2007, 458, p 226–234

A.P. Zhilyaev and T.G. Langdon, Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications, Prog. Mater. Sci., 2008, 53, p 893–979

B. Han and Z. Xu, Microstructural Evolution of Fe–32%Ni Alloy During Large Strain Multi-Axial Forging, Mater. Sci. Eng. A, 2007, 447, p 119–124

Y. Beygelzimer, V. Varyukhin, S. Synkov, and D. Orlov, Useful Properties of Twist Extrusion, Mater. Sci. Eng. A, 2009, 503, p 14–17

D.H. Shin, J.J. Park, Y.S. Kim, and K.T. Park, Constrained Groove Pressing and its Application to Grain Refinement of Aluminum, Mater. Sci. Eng. A, 2002, 328, p 98–103

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong, Ultra-Fine Grained Bulk Aluminum Produced by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 1998, 39, p 1221–1227

B. Mani, M. Jahedi, and M.H. Paydar, A Modification on ECAP Process by Incorporating Torsional Deformation, Mater. Sci. A, 2011, 528, p 4159–4165

B. Talebanpour, R. Ebrahimi, and K. Janghorban, Microstructural and Mechanical Properties of Commercially Pure Aluminum Subjected to Dual Equal Channel Lateral Extrusion, Mater. Sci. Eng. A, 2009, 527, p 141–145

K. Nakashima, Z. Horita, M. Nemoto, and T.G. Langdon, Influence of Pressing Speed on Microstructural Development in Equal-Channel Angular Pressing, Metall. Mater. Trans. A, 1999, 30, p 1989–1997

X. Ma, M.R. Barnett, and Y.H. Kim, Forward Extrusion Through Steadily Rotating Conical Dies. Part I: Experiments, Int. J. Mech. Sci., 2004, 46, p 449–464

A.P. Shpak, V.N. Varyukhin, V.I. Tkatch, V.V. Maslov, Y.Y. Beygelzimer, S.G. Synkov, V.K. Nosenko, and S.G. Rassolov, Nanostructured Al86Gd6Ni6Co2 Bulk Alloy Produced by Twist Extrusion of Amorphous Melt-Spun Ribbons, Mater. Sci. Eng. A, 2006, 425, p 172–177

S.A.A. Akbari Mousavi, Sh. Ranjbar Bahadori, and A.R. Shahab, Numerical and Experimental Studies of the Plastic Strains Distribution Using Subsequent Direct Extrusion After Three Twist Extrusion Passes, Mater. Sci. Eng. A, 2010, 527, p 3967–3974

D. Orlov, Y. Beygelzimer, S. Synkov, V. Varyukhin, N. Tsuji, and Z. Horita, Plastic Flow, Structure and Mechanical Properties in Pure Al Deformed by Twist Extrusion, Mater. Sci. Eng. A, 2009, 519, p 105–111

V.M. Segal, Severe Plastic Deformation: Simple Shear Versus Pure Shear, Mater. Sci. Eng. A, 2002, 338, p 331–344

R. Kocicha, M. Greger, M. Kursa, I. Szurman, I. Szurman, and A. Machackova, Twist Channel Angular Pressing (TCAP) as a Method for Increasing the Efficiency of SPD, Mater. Sci. Eng. A, 2010, 527, p 6386–6392

N. Bay, Friction Stress and Normal Stress in Bulk Metal-Forming Processes, J. Mech. Work. Technol., 1987, 14, p 203–223

W. Wei, A.V. Nagasekhar, G. Chen, Y. Tick-Hon, and K.X. Wei, Origin of Inhomogenous Behavior During Equal Channel Angular Pressing, Scr. Mater., 2006, 54, p 1865–1869

N. El Mahallawy, F.A. Shehata, M. Abd El Hameed, M. Ibrahim Abd El Aal, and H.S. Kim, 3D FEM Simulations for the Homogeneity of Plastic Deformation in Al–Cu Alloys During ECAP, Mater. Sci. Eng. A, 2010, 527, p 1404–1410

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon, Principle of Equal-Channel Angular Pressing for the Processing of Ultra-Fine Grained Materials, Scr. Mater., 1996, 35, p 143–146

O.F. Sonmez and A. Demir, Analytical Relations Between Hardness and Strain for Cold Formed Parts, J. Mater. Process. Technol., 2007, 186, p 163–236

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bisadi, H., Mohamadi, M.R., Miyanaji, H. et al. A Modification on ECAP Process by Incorporating Twist Channel. J. of Materi Eng and Perform 22, 875–881 (2013). https://doi.org/10.1007/s11665-012-0323-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0323-z