Abstract

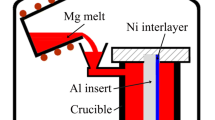

In this work, microstructure, mechanical properties and fracture behavior of the magnesium/steel bimetal using compound casting assisted with hot-dip aluminizing were investigated, and the interface bonding mechanism of the magnesium/steel bimetal were also analyzed. The results indicate that the magnesium/steel bimetal obtained without hot-dip aluminizing had larger gaps through the whole interface without reaction layers between magnesium and steel, leading to a poor mechanical bonding. After the steel substrate was hot-dip aluminized, an intermetallic layer along with an Al topcoat layer were formed on the surface of the steel substrate, and the intermetallic layer was constituted by Fe2Al5, τ10-Al9Fe4Si3, FeAl3 and τ6-Al4.5FeSi phases. In the case of the magnesium/steel bimetal obtained with hot-dip aluminizing, a compact and uniform interface layer with an average thickness of about 17 μm that consisted of Fe2Al5, τ10-Al9Fe4Si3, FeAl3 and Al12Mg17 intermetallic compounds was formed between the magnesium and the steel, obtaining a superior metallurgical bonding. The interface layer had much higher nano-hardnesses compared to the magnesium and steel matrixes, and its average nano-hardness was up to 11.1 GPa, while there were respectively 1.1 and 4.2 GPa for the magnesium and steel matrixes. The shear strength of the magnesium/steel bimetal with hot-dip aluminizing reached to 23.3 MPa, which increased by 8.59 times than that of the composites without hot-dip aluminizing. The fracture of the magnesium/steel bimetal with hot-dip aluminizing represented a brittle fracture nature, initiating from the interface layer.

Graphic Abstract

Similar content being viewed by others

References

T. Lee, M. Yamasaki, Y. Kawamura, J. Go, S.H. Park, Met. Mater. Int. 25, 372–380 (2019)

W.J. Kim, K.H. Han, Y.J. Lee, H. Kim, E.K. Lee, Met. Mater. Int. 24, 720–729 (2018)

W.M. Jiang, G.Y. Li, Z.T. Fan, L. Wang, F.C. Liu, Metall. Mater. Trans. A 47, 2462–2470 (2016)

Y.J. Kim, S.-H. Kim, J.U. Lee, J.O. Choi, H.S. Kim, Y.M. Kim, Y. Kim, S.H. Park, Mater. Sci. Eng. A 708, 405–410 (2017)

Z.S. Yao, G. Xu, Z.Y. Jiang, J.Y. Tian, Q. Yuan, H.W. Ma, Met. Mater. Int. 25, 1151–1160 (2019)

J.I. Yoon, J. Jung, H.H. Lee, J.Y. Kim, H.S. Kim, Met. Mater. Int. 25, 1161–1169 (2019)

W.M. Jiang, G.Y. Li, Y. Wu, X.W. Liu, Z.T. Fan, J. Mater. Process. Technol. 258, 239–250 (2018)

J. Cheng, J.H. Zhao, J.Y. Zhang, Y. Guo, K. He, J.J. Shangguan, F.L. Wen, Materials 12, 1–14 (2019)

V.K. Patel, S.D. Bhole, D.L. Chen, Mater. Des. 45, 236–240 (2013)

L. Liu, X. Qi, Z. Wu, Mater. Lett. 64, 89–92 (2010)

A.M. Nasiri, P. Chartrand, D.C. Weckman, N.Y. Zhou, Metall. Mater. Trans. A 44, 1937–1946 (2013)

G. Song, J.W. Yu, T.T. Li, J.F. Wang, L.M. Liu, J. Manuf. Process. 31, 131–138 (2018)

S. Jana, Y. Hovanski, G.J. Grant, Metall. Mater. Trans. A 41, 3173–3182 (2010)

Y.N. Wei, J.L. Li, J.T. Xiong, F. Huang, F.S. Zhang, Mater. Des. 33, 111–114 (2012)

L.Q. Li, C.W. Tan, Y.B. Chen, W. Guo, C.X. Mei, J. Mater. Process. Technol. 213, 361–375 (2013)

L. Li, C. Tan, Y. Chen, W. Guo, C. Mei, X. Hu, Metall. Mater. Trans. A 43, 4740–4754 (2012)

W.M. Elthalabawy, T.I. Khan, Mater. Charact. 61, 703–712 (2010)

W. Elthalabawy, T. Khan, J. Mater. Sci. Technol. 27, 22–28 (2011)

L. Liu, L. Xiao, D.L. Chen, J.C. Feng, S. Kim, Y. Zhou, Mater. Des. 45, 336–342 (2013)

Y. Feng, Y. Li, Z. Luo, Z. Ling, Z. Wang, J. Mater. Process. Technol. 236, 114–122 (2016)

V.K. Patel, S.D. Bhole, D.L. Chen, J. Mater. Process. Technol. 214, 811–817 (2014)

M. Shakil, N.H. Tariq, M. Ahmad, M.A. Choudhary, J.I. Akhter, S.S. Babu, Mater. Des. 55, 263–273 (2014)

C.W. Tan, B. Chen, X.G. Song, L. Zhou, S.H. Meng, L.Q. Li, J.C. Feng, Weld. J. 95, 384–394 (2016)

M. Ding, S.S. Liu, Y. Zheng, Y.C. Wang, H. Li, W.Q. Xing, X.Y. Yu, P. Dong, Mater. Des. 88, 375–383 (2015)

R. Cao, H.X. Zhu, Q. Wang, C. Dong, Q. Lin, J.H. Chen, Mater. Sci. Technol. 32, 1805–1817 (2016)

A.M. Nasiri, M.Y. Lee, D.C. Weckman, Y. Zhou, Metall. Mater. Trans. A 455, 749–5766 (2014)

Y.G. Miao, D.F. Han, X.F. Xu, B.T. Wu, Mater. Charact. 93, 87–93 (2014)

Y.C. Chen, K. Nakata, Mater. Des. 30, 3913–3919 (2009)

M. Sacerdote-Peronnet, E. Guiot, F. Bosselet, O. Dezellus, D. Rouby, J.C. Viala, Mater. Sci. Eng., A 445–446, 296–301 (2007)

W.M. Jiang, Z.T. Fan, G.Y. Li, C. Li, J. Alloys Compd. 678, 249–257 (2016)

U.R. Kattner, T.B. Massalski, Binary alloy phase diagrams (ASM International, Material Park, 1990)

W.M. Jiang, Z.T. Fan, C. Li, J. Mater. Process. Technol. 226, 25–31 (2015)

N. Krendelsberger, F. Weitzer, J.C. Schuster, Metall. Mater. Trans. A 38, 1681–1691 (2007)

Y. Lia, P. Ochin, A. Quivy, P. Telolahy, B. Legendre, J. Alloys Compd. 298, 198–202 (2000)

H. Zhang, Y.Q. Chen, A.A. Luo, Scr. Mater. 86, 52–55 (2014)

J.C. Liu, J. Hu, X.Y. Nie, H.X. Li, Q. Du, J.S. Zhang, L.Z. Zhuang, Mater. Sci. Eng., A 635, 70–76 (2015)

W.M. Jiang, Z.T. Fan, G.Y. Li, L. Yang, X.W. Liu, Metall. Mater. Trans. A 47, 6487–6497 (2016)

O. Dezellus, M. Zhe, F. Bosselet, D. Rouby, J.C. Viala, Mater. Sci. Eng., A 528, 2795–2803 (2011)

Z.L. Jiang, Z.T. Fan, W.M. Jiang, G.Y. Li, Y. Wu, F. Guan, H.X. Jiang, J. Mater. Process. Technol. 261, 149–158 (2018)

G.Y. Li, W.M. Jiang, W.C. Yang, Z.L. Jiang, F. Guan, H.X. Jiang, Z.T. Fan, Metall. Mater. Trans. A 50, 1076–1090 (2019)

D.X. Ren, L.M. Liu, Mater. Des. 59, 369–376 (2014)

R.W. Richards, R.D. Jones, P.D. Clements, H. Clarke, Int. Mater. Rev. 39, 191–212 (1994)

H. Ma, G.L. Qin, L.Y. Wang, X.M. Meng, L. Chen, Mater. Des. 90, 330–339 (2016)

W.M. Jiang, Z.T. Fan, G.Y. Li, X.W. Liu, F.C. Liu, J. Alloys Compd. 688, 742–751 (2016)

S. Basak, H. Das, T.K. Pal, M. Shome, Mater. Charact. 112, 229–237 (2016)

Y. Du, J.C. Schuster, Z.K. Liu, R.X. Hu, P. Nash, W.H. Sun, W.W. Zhang, J. Wang, L.J. Zhang, C.Y. Tang, Z.J. Zhu, S.H. Liu, Y.F. Ouyang, W.Q. Zhang, N. Krendelsberger, Intermetallics 16, 554–570 (2008)

H. Springer, A. Kostka, E.J. Payton, D. Raabe, A. Kaysser-Pyzalla, G. Eggeler, Acta Mater. 59, 1586–1600 (2011)

V. Raghavan, J. Phase Equilib. Diffus. 30, 184–188 (2009)

A. Bouayad, Ch. Gerometta, A. Belkebir, A. Ambari, Mater. Sci. Eng., A 363, 53–61 (2003)

Acknowledgements

This work described in this paper was financially supported by the National MCF Energy R&D Program (No. 2018YFE0313300) and the National Natural Science Foundation of China (No. 51775204), and the Natural Science Foundation of Hubei Province, China (No. 2017CFB488). The authors would also like to thank the support of the Research Project of State Key Laboratory of Materials Processing and Die and Mould Technology and the Analytical and Testing Center, HUST.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, W., Jiang, H., Li, G. et al. Microstructure, Mechanical Properties and Fracture Behavior of Magnesium/Steel Bimetal Using Compound Casting Assisted with Hot-Dip Aluminizing. Met. Mater. Int. 27, 2977–2988 (2021). https://doi.org/10.1007/s12540-019-00606-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00606-7