Abstract

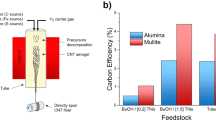

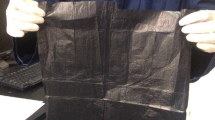

Floating catalysis chemical vapor deposition (FCCVD) direct spinning process is an attractive method for fabrication of carbon nanotube fibers (CNTFs). However, the intrinsic structural defects, such as entanglement of the constituent carbon nanotubes (CNTs) and inter-tube gaps within the FCCVD CNTFs, hinder the enhancement of mechanical/electrical properties and the realization of practical applications of CNTFs. Therefore, achieving a comprehensive reassembly of CNTFs with both high alignment and dense packing is particularly crucial. Herein, an efficient reinforcing strategy for FCCVD CNTFs was developed, involving chlorosulfonic acid-assisted wet stretching for CNT realigning and mechanical rolling for densification. To reveal the intrinsic relationship between the microstructure and the mechanical/electrical properties of CNTFs, the microstructure evolution of the CNTFs was characterized by cross-sectional scanning electron microscopy (SEM), wide angle X-ray scattering (WAXS), polarized Raman spectroscopy and Brunauer–Emmett–Teller (BET) analysis. The results demonstrate that this strategy can improve the CNT alignment and eliminate the inter-tube voids in the CNTFs, which will lead to the decrease of mean distance between CNTs and increase of inter-tube contact area, resulting in the enhanced inter-tube van der Waals interactions. These microstructural evolutions are beneficial to the load transfer and electron transport between CNTs, and are the main cause of the significant enhancement of mechanical and electrical properties of the CNTFs. Specifically, the tensile strength, elastic modulus and electrical conductivity of the high-performance CNTFs are 7.67 GPa, 230 GPa and 4.36 × 106 S/m, respectively. It paves the way for further applications of CNTFs in high-end functional composites.

Similar content being viewed by others

References

Bulmer, J. S.; Kaniyoor, A.; Elliott, J. A. A meta-analysis of conductive and strong carbon nanotube materials. Adv. Mater. 2021, 33, 2008432.

Bai, Y. X.; Zhang, R. F.; Ye, X.; Zhu, Z. X.; Xie, H. H.; Shen, B. Y.; Cai, D. L.; Liu, B. F.; Zhang, C. X.; Jia, Z. et al. Carbon nanotube bundles with tensile strength over 80 GPa. Nat. Nanotechnol. 2018, 13, 589–595.

Wang, F.; Zhao, S. M.; Jiang, Q. Y.; Li, R.; Zhao, Y. L.; Huang, Y.; Wu, X. K.; Wang, B. S.; Zhang, R. F. Advanced functional carbon nanotube fibers from preparation to application. Cell Rep. Phys. Sci. 2022, 3, 100989.

Lu, W. B.; Zu, M.; Byun, J. H.; Kim, B. S.; Chou, T. W. State of the art of carbon nanotube fibers: Opportunities and challenges. Adv. Mater. 2012, 24, 1805–1833.

Xu, W.; Chen, Y.; Zhan, H.; Wang, J. N. High-strength carbon nanotube film from improving alignment and densification. Nano Lett. 2016, 16, 946–952.

Cho, Y. S.; Lee, J. W.; Kim, J.; Jung, Y.; Yang, S. J.; Park, C. R. Superstrong carbon nanotube yarns by developing multiscale bundle structures on the direct spin-line without post-treatment. Adv. Sci. 2022, 10, 2204250.

Zhang, S. L.; Nguyen, N.; Leonhardt, B.; Jolowsky, C.; Hao, A. Y.; Park, J. G.; Liang, R. Carbon-nanotube-based electrical conductors: Fabrication, optimization, and applications. Adv. Electron. Mater. 2019, 5, 1800811.

Zhang, S.; Chen, G. Q.; Qu, T. M.; Wei, J. Q.; Yan, Y. F.; Liu, Q.; Zhou, M. R.; Zhang, G.; Zhou, Z. X.; Gao, H. et al. A novel aluminum-carbon nanotubes nanocomposite with doubled strength and preserved electrical conductivity. Nano Res. 2021, 14, 2776–2782.

Qiao, J.; Wu, Y. L.; Zhu, C. F.; Dong, L. Z.; Wu, K. J.; Wang, Y. L.; Yang, W.; Li, M.; Di, J. T.; Li, Q. W. High-performance carbon nanotube/polyaniline artificial yarn muscles working in biocompatible environments. Nano Res. 2023, 16, 4143–4151.

Liu, D. P.; Yang, Z. P.; Zhang, Y. Y.; Wang, S.; Niu, Y. T.; Yang, J. F.; Yang, X. Y.; Fu, H. L.; Chen, L.; Yong, Z. Z. et al. Tailoring aligned and densified carbon nanotube@graphene coaxial yarn for 3D thermally conductive networks. Carbon 2023, 208, 322–329.

Gong, Q.; Yu, Y. Y.; Kang, L. X.; Zhang, M. C.; Zhang, Y. Y.; Wang, S. S.; Niu, Y. T.; Zhang, Y. Y.; Di, J. T.; Li, Q. W. et al. Modulus-tailorable, stretchable, and biocompatible carbonene fiber for adaptive neural electrode. Adv. Funct. Mater. 2022, 32, 2107360.

Lee, D.; Kim, S. G.; Hong, S.; Madrona, C.; Oh, Y.; Park, M.; Komatsu, N.; Taylor, L. W.; Chung, B.; Kim, J. et al. Ultrahigh strength, modulus, and conductivity of graphitic fibers by macromolecular coalescence. Sci. Adv. 2022, 8, eabn0939.

Li, Q. W.; Zhang, X. F.; DePaula, R. F.; Zheng, L. X.; Zhao, Y. H.; Stan, L.; Holesinger, T. G.; Arendt, P. N.; Peterson, D. E.; Zhu, Y. T. Sustained growth of ultralong carbon nanotube arrays for fiber spinning. Adv. Mater. 2006, 18, 3160–3163.

Kim, S. G.; Choi, G. M.; Jeong, H. D.; Lee, D.; Kim, S.; Ryu, K. H.; Lee, S.; Kim, J.; Hwang, J. Y.; Kim, N. D. et al. Hierarchical structure control in solution spinning for strong and multifunctional carbon nanotube fibers. Carbon 2022, 196, 59–69.

Zhao, Y.; Wei, J. Q.; Vajtai, R.; Ajayan, P. M.; Barrera, E. V. Iodine doped carbon nanotube cables exceeding specific electrical conductivity of metals. Sci. Rep. 2011, 1, 83.

Li, Y. L.; Kinloch, I. A.; Windle, A. H. Direct spinning of carbon nanotube fibers from chemical vapor deposition synthesis. Science 2004, 304, 276–278.

Janas, D.; Koziol, K. K. Carbon nanotube fibers and films: Synthesis, applications and perspectives of the direct-spinning method. Nanoscale 2016, 8, 19475–19490.

Smail, F.; Boies, A.; Windle, A. Direct spinning of CNT fibres: Past, present and future scale up. Carbon 2019, 152, 218–232.

Cho, H.; Lee, H.; Oh, E.; Lee, S. H.; Park, J.; Park, H. J.; Yoon, S. B.; Lee, C. H.; Kwak, G. H.; Lee, W. J. et al. Hierarchical structure of carbon nanotube fibers, and the change of structure during densification by wet stretching. Carbon 2018, 136, 409–416.

Han, B. S.; Xue, X.; Xu, Y. J.; Zhao, Z. Y.; Guo, E. Y.; Liu, C.; Luo, L. S.; Hou, H. L. Preparation of carbon nanotube film with high alignment and elevated density. Carbon 2017, 122, 496–503.

Liu, Q. L.; Li, M.; Gu, Y. Z.; Zhang, Y. Y.; Wang, S. K.; Li, Q. W.; Zhang, Z. G. Highly aligned dense carbon nanotube sheets induced by multiple stretching and pressing. Nanoscale 2014, 6, 4338–4344.

Lee, S. H.; Park, J.; Park, J. H.; Lee, D. M.; Lee, A.; Moon, S. Y.; Lee, S. Y.; Jeong, H. S.; Kim, S. M. Deep-injection floating-catalyst chemical vapor deposition to continuously synthesize carbon nanotubes with high aspect ratio and high crystallinity. Carbon 2021, 173, 901–909.

Weller, L.; Smail, F. R.; Elliott, J. A.; Windle, A. H.; Boies, A. M.; Hochgreb, S. Mapping the parameter space for direct-spun carbon nanotube aerogels. Carbon 2019, 146, 789–812.

Zhou, T.; Niu, Y. T.; Li, Z.; Li, H. F.; Yong, Z. Z.; Wu, K. J.; Zhang, Y. Y.; Li, Q. W. The synergetic relationship between the length and orientation of carbon nanotubes in direct spinning of high-strength carbon nanotube fibers. Mater. Design 2021, 203, 109557.

Wu, K. J.; Zhang, Y. Y.; Yong, Z. Z.; Li, Q. W. Continuous preparation and performance enhancement techniques of carbon nanotube fibers. Acta Phys. Chim. Sin. 2022, 38, 2106034.

Li, L. J.; Sun, T. Z.; Lu, S. C.; Chen, Z.; Xu, S. C.; Jian, M. Q.; Zhang, J. Graphene interlocking carbon nanotubes for high-strength and high-conductivity fibers. ACS Appl. Mater. Interfaces 2023, 15, 5701–5708.

Wang, J. N.; Luo, X. G.; Wu, T.; Chen, Y. High-strength carbon nanotube fibre-like ribbon with high ductility and high electrical conductivity. Nat. Commun. 2014, 5, 3848.

Lee, J.; Lee, D. M.; Jung, Y.; Park, J.; Lee, H. S.; Kim, Y. K.; Park, C. R.; Jeong, H. S.; Kim, S. M. Direct spinning and densification method for high-performance carbon nanotube fibers. Nat. Commun. 2019, 10, 2962.

Oh, E.; Cho, H.; Kim, J.; Kim, J. E.; Yi, Y.; Choi, J.; Lee, H.; Im, Y. H.; Lee, K. H.; Lee, W. J. Super-strong carbon nanotube fibers achieved by engineering gas flow and postsynthesis treatment. ACS Appl. Mater. Interfaces 2020, 12, 13107–13115.

Han, Y.; Zhang, X. H.; Yu, X. P.; Zhao, J. N.; Li, S.; Liu, F.; Gao, P.; Zhang, Y. Y.; Zhao, T.; Li, Q. W. Bio-inspired aggregation control of carbon nanotubes for ultra-strong composites. Sci. Rep. 2015, 5, 11533.

Beese, A. M.; Wei, X. D.; Sarkar, S.; Ramachandramoorthy, R.; Roenbeck, M. R.; Moravsky, A.; Ford, M.; Yavari, F.; Keane, D. T.; Loutfy, R. O. et al. Key factors limiting carbon nanotube yarn strength: Exploring processing-structure-property relationships. ACS Nano 2014, 8, 11454–11466.

Alemán, B.; Reguero, V.; Mas, B.; Vilatela, J. J. Strong carbon nanotube fibers by drawing inspiration from polymer fiber spinning. ACS Nano 2015, 9, 7392–7398.

Jung, Y.; Cho, Y. S.; Lee, J. W.; Oh, J. Y.; Park, C. R. How can we make carbon nanotube yarn stronger. Compos. Sci. Technol. 2018, 166, 95–108.

Ericson, L. M.; Fan, H.; Peng, H. Q.; Davis, V. A.; Zhou, W.; Sulpizio, J.; Wang, Y. H.; Booker, R.; Vavro, J.; Guthy, C. et al. Macroscopic, neat, single-walled carbon nanotube fibers. Science 2004, 305, 1447–1450.

Vilatela, J. J.; Elliott, J. A.; Windle, A. H. A model for the strength of yarn-like carbon nanotube fibers. ACS Nano 2011, 5, 1921–1927.

Behabtu, N.; Young, C. C.; Tsentalovich, D. E.; Kleinerman, O.; Wang, X.; Ma, A. W. K.; Bengio, E. A.; Ter Waarbeek, R. F.; De Jong, J. J.; Hoogerwerf, R. E. et al. Strong, light, multifunctional fibers of carbon nanotubes with ultrahigh conductivity. Science 2013, 339, 182–186.

Song, L. M.; Zhang, F.; Chen, Y. Q.; Guan, L.; Zhu, Y. Q.; Chen, M.; Wang, H. L.; Putra, B. R.; Zhang, R.; Fan, B. B. Multifunctional SiC@SiO2 nanofiber aerogel with ultrabroadband electromagnetic wave absorption. Nano-Micro Lett. 2022, 14, 152.

Davies, R. J.; Riekel, C.; Koziol, K. K.; Vilatela, J. J.; Windle, A. H. Structural studies on carbon nanotube fibres by synchrotron radiation microdiffraction and microfluorescence. J. Appl. Cryst. 2009, 42, 1122–1128.

Li, S.; Park, J. G.; Liang, Z. Y.; Siegrist, T.; Liu, T.; Zhang, M.; Cheng, Q. F.; Wang, B.; Zhang, C. In situ characterization of structural changes and the fraction of aligned carbon nanotube networks produced by stretching. Carbon 2012, 50, 3859–3867.

Severino, J.; Yang, J. M.; Carlson, L.; Hicks, R. Progression of alignment in stretched CNT sheets determined by wide angle X-ray scattering. Carbon 2016, 100, 309–317.

Han, Y.; Li, S.; Chen, F. H.; Zhao, T. Multi-scale alignment construction for strong and conductive carbon nanotube/carbon composites. Mater. Today Commun. 2016, 6, 56–68.

Miaudet, P.; Badaire, S.; Maugey, M.; Derré, A.; Pichot, V.; Launois, P.; Poulin, P.; Zakri, C. Hot-drawing of single and multiwall carbon nanotube fibers for high toughness and alignment. Nano Lett. 2005, 5, 2212–2215.

Gommans, H. H.; Alldredge, J. W.; Tashiro, H.; Park, J.; Magnuson, J.; Rinzler, A. G. Fibers of aligned single-walled carbon nanotubes: Polarized Raman spectroscopy. J. Appl. Phys. 2000, 88, 2509–2514.

Nesbitt, S.; Scott, W.; Macione, J.; Kotha, S. Collagen fibrils in skin orient in the direction of applied uniaxial load in proportion to stress while exhibiting differential strains around hair follicles. Materials 2015, 8, 1841–1857.

Acknowledgements

The authors appreciate the financial support of the National Key Research and Development Program of China (No. 2022YFA1203303), the National Natural Science Foundation of China (Nos. 52162007, 52163032 and 52202032), the China Postdoctoral Science Foundation (No. 2022M712321), the Beijing Natural Science Foundation (No. 2222094), the Jiangsu Province Postdoctoral Research Funding Program (No. 2021K473C), and the Jiangxi Provincial Natural Science Foundation (Nos. 20224ACB204011 and 20202BAB204006).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Wu, K., Wang, B., Niu, Y. et al. Carbon nanotube fibers with excellent mechanical and electrical properties by structural realigning and densification. Nano Res. 16, 12762–12771 (2023). https://doi.org/10.1007/s12274-023-6157-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-023-6157-1