Abstract

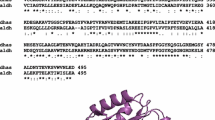

1,3-propanediol oxidoreductase (DhaT) of Klebsiella pneumoniae converts 3-hydroxypropionaldehyde (3-HPA) to 1,3-propanediol (1,3-PD) during microbial production of 1,3-PD from glycerol. In this study, DhaT from newly isolated K. pneumoniae J2B was cloned, expressed, purified, and studied for its kinetic properties. It showed, on its physiological substrate 3-HPA, higher activity than similar aldehydes such as acetaldehyde, propionaldehyde and butyraldehyde. The turnover numbers (k cat , 1/s) were estimated as 59.4 for the forward reaction (3-HPA to 1,3-PD at pH 7.0) and 10.0 for the reverse reaction (1,3-PD to 3-HPA at pH 9.0). The Michaelis constants (K m , mM) were 0.77 (for 3-HPA) and 0.03 (for NADH) for the forward reaction (at pH 7.0), and 7.44 (for 1,3-PD) and 0.23 (for NAD+) for the reverse reaction (at pH 9.0). Between these forward and reverse reactions, the optimum temperature and pH were significantly different (37°C and 7.0 vs. 55°C and 9.0, respectively). These results indicate that, under physiological conditions, DhaT mostly catalyzes the forward reaction. The enzyme was seriously inhibited by heavy metal ions such as Ag+ and Hg2+. DhaT was highly unstable when incubated with its own substrate 3-HPA, indicating the necessity of enhancing its stability for improved 1,3-PD production from glycerol.

Similar content being viewed by others

References

Zeng, A. P. and H. Biebl (2002) Bulk chemicals from biotechnology: the case of 1,3-propanediol production and the new trends. Adv. Biochem. Eng. Biotechnol. 74: 239–259.

Biebl, H., K. Menzel, A. P. Zeng, and W. D. Deckwer (1999) Microbial production of 1,3-propanediol. Appl. Microbiol. Biotechnol. 52: 289–297.

Nakamura, C. E. and G. M. Whited (2003) Metabolic engineering for the microbial production of 1,3-propanediol. Curr. Opin. Biotechnol. 14: 454–459.

Schaefer, L., T. A. Auchtung, K. E. Hermans, D. Whitehead, B. Borhan, and R. A. Britton (2010) The antimicrobial compound reuterin (3-hydroxypropionaldehyde) induces oxidative stress via interaction with thiol groups. Microbiol. 156: 1589–1599.

Barbirato, F., P. Soucaille, and A. Bories (1996) Physiologic mechanisms involved in accumulation of 3-hydroxypropionaldehyde during fermentation of glycerol by Enterobacter agglomerans. Appl. Environ. Microbiol. 62: 4405–4409.

Hao, J., W. Wang, J. Tian, J. Li, and D. Liu (2008) Decrease of 3-hydroxypropionaldehyde accumulation in 1,3-propanediol production by over-expressing dhaT gene in Klebsiella pneumoniae TUAC01. J. Ind. Microbiol. Biotechnol. 35: 735–741.

Fenghuan, W., Q. Huijin, H. He, and T. Tan (2005) High-level expression of the 1,3-propanediol oxidoreductase from Klebsiella pneumoniae in Escherichia coli. Mol Biotechnol. 31: 21–29.

Johnson, E. A. and E. C. Lin (1987) Klebsiella pneumoniae 1,3-propanediol: NAD+ oxidoreductase. J. Bacteriol. 169: 2050–2054.

Hall, R. H. and E. S. Stern (1950) Acid-catalyzed hydration of acrylaldehyde: Kinetics of the reaction and isolation of ß-hydroxypropionaldehyde. J. Chem. Soc. 490–498.

Sambrook, J. and D. Russell (2001) Molecular cloning: A Laboratory Manual. 3rd edition, Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY, USA.

Arasu, M. V., V. Kumar, A. Somasundar, S. Hyohak, R. S. Celladurai, H. J. Lee, D. Seung and S. Park (2011) Isolation and characterization of the new Klebsiella pneumoniae J2B strain showing improved growth characteristics with reduced lipopolysaccharide formation Biotechnol. Bioproc. Eng. 16: 1134–1143.

Laemmli, U. K. (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Natur. 227: 680–685.

Bradford, M. M. (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72: 248–254.

Webb, B. and A. Sali (2014) Comparative protein structure modeling with modeller. Curr. Protoc. Bioinformatics. 47: 5.6.1-5.6.32.

Shen, M. Y. and A. Sali (2006) Statistical potential for assessment and prediction of protein structures. Protein Sci. 15: 2507–2524.

Lovell, S. C., I. W. Davis, W. B. III Arendall, P. I. D. Bakker, J. M. Word, M. G. Prisant, J. S. Richardson, and D. C. Richardson (2003) Structure validation by C alpha geometry: phi, psi and C beta deviation. Proteins. 50: 437–450.

Eisenberg, D., R. Luthy, and J. U. Bowie (1997) VERIFY3D: Assessment of protein models with three-dimensional profiles. Methods Enzymol. 277: 396–404.

Dong, X. and Y. Zhang (2011) Improving the physical realism and structural accuracy of protein models by a two-step atomiclevel energy minimization. Biophys. J. 101: 2525–2534.

Morris, G. M., R. Huey, W. Lindstrom, M. F. Sanner, R. K. Belew, D. S. Goodsell, and A. J. Olson (2009) Autodock4 and AutoDockTools4: Automated docking with selective receptor flexibility. J. Comput. Chem. 30: 2785–2791.

Yang, J., A. Roy, and Y. Zhang (2013) Protein-ligand binding site recognition using complementary binding-specific substructure comparison and sequence profile alignment. Bioinformatics. 29: 2588–2595.

Marcal, D., A. T. Rego, M. A. Carrondo, and F. J. Enguita (2009) 1,3-Propanediol dehydrogenase from Klebsiella pneumoniae: Decameric quaternary structure and possible subunit cooperativity. J. Bacteriol. 19: 1143–1151.

Ma., C., L. Zhang, J. Dai, and Z. Xiu (2010) Relaxing the coenzyme specificity of 1,3-propanediol oxidoreductase from Klebsiella pneumoniae by rational design. J. Biotechnol. 146: 173–178.

Daniel, R., R. Boenigk, and G. Gottschalk (1995) Purification of 1,3-propanediol dehydrogenase from Citrobacter freundii and cloning, sequencing, and overexpression of the corresponding gene in Escherichia coli. J. Bacteriol. 177: 2151–2156.

Malaoui, H. and R. Marczak (2000) Purification and characterization of the 1,3-propanediol dehydrogenase of Clostridium butyricum E5. Enz. Microb. Technol. 27: 399–405.

Barbirato, F., A. Larguier, T. Conte, S. Astruc, and A. Bories (1997) Sensitivity to pH, product inhibition, and inhibition by NAD+ of 1,3-propanediol dehydrogenase purified from Enterobacter agglomerans CNCM 1210. Arch. Microbiol. 168: 160–163.

Elleuche, S., K. Fodor, B. Klippel, A. von der Heyde, M. Wilmanns, and G. Antranikian G (2013) Structural and biochemical characterization of a NAD-dependent alcohol dehydrogenase from Oenococcus oeni as a new model molecule for industrial biotechnology applications. Appl. Microbiol. Biotechnol. 97: 8963–8975.

Li, W., I. Ng, B. Fang, J. Yu, and G. Zhang (2011) Codon optimization of 1,3-propanediol oxidoreductase expression in Escherichia coli and enzymatic properties. Electron. J. Biotechnol. 14: 7-7.

Qi, X., W. Deng, F. Wang, Q. Guo, H. Chen, L. Wang, X. He, and R. Huang (2013) Molecular cloning, co-expression, and characterization of glycerol dehydratase and 1,3-propanediol dehydrogenase from Citrobacter freundii. Mol. Biotechnol. 54: 469–474.

Yan, Z., A. Somasundar, S. Eunhee, S. K. Ainala, S. G. Lee, B. Madan, J. H. Xu, and S. Park (2014) NADH-dependent lactate dehydrogenase from Alcaligenes eutrophus H16 reduces 2-oxoadipate to 2-hydroxyadipate. Biotechnol. Bioproc. Eng. 19: 1048–1057.

Vollenweider, S., S. Evers, K. Zurbriggen, and C. Lacroix (2010) Unraveling the hydroxypropionaldehyde (HPA) system: An active antimicrobial agent against human pathogens. J. Agric. Food Chem. 58: 10315–10322.

Talarico, T. L., L. T. Axelsson, J. Novotny, M. Fiuzat, and W. J. Dobrogosz (1990) Utilization of glycerol as a hydrogen acceptor by Lactobacillus reuteri: Purification of 1,3-propanediol: NAD oxidoreductase. Appl. Environ. Microbiol. 56: 943–948.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lama, S., Ro, S.M., Seol, E. et al. Characterization of 1,3-propanediol oxidoreductase (DhaT) from Klebsiella pneumoniae J2B. Biotechnol Bioproc E 20, 971–979 (2015). https://doi.org/10.1007/s12257-015-0635-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-015-0635-6