Abstract

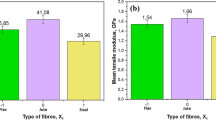

The objectives and novelty of this paper are to create a hybrid-natural fibre composite by the Response Surface Methodology RMS technique, and then compared this hybrid composite with the individual fibre reinforced composites in the bending test. The first aim of this study is devoted to analyse, modelize and optimise the various independent variables such as the type of fibres (X1), the types of chemical treatment (X2), the volume fraction of fibre (X3) and the treatment duration (X4) used on the output parameters which are the mechanical characteristics namely, ultimate flexural stress and flexural modulus in the bending test using a Box-Behnken experimental design. Mathematical models for ultimate flexural strength and flexural modulus were developed using the response surface methodology (RSM). These models would be helpful in selecting independent variables in order to maximize the flexural mechanical properties. Statistical analysis of the results showed that selected variables had a significant effect on the flexural properties, except the treatment time that has a very weak significance effect on the flexural properties. In the second section, the impact behaviors of the natural hybrid composites found by the RMS method were confirmed experimentally. Finally, the experimental results indicate that the flexural properties of the natural hybrid composites increase with an increase in the composition of jute fibres.

Similar content being viewed by others

References

B. Vijaya Ramnath, V. M. Manickavasagam, C. Elanchezhian, C. Vinodh Krishna, S. Karthik, and K. Saravanan, Mater. Des., 60, 652 (2014).

A. G. Adeniyi, D. V. Onifade, J. O. Ighalo, and A. S. Adeoye, Compos. Part B: Eng., 176, 107305 (2019).

V. Agopyan, GIasgow Blackie, 242 (1988).

S. A. S. Goulart, T. A. Oliveira, A. Teixeira, P. C. Mileo, and D. R. Mulinari, Proc. Eng., 10, 2039 (2011).

S. Ben Brahim and Ben R. Cheikh, Compos. Sci. Tech., 67, 147 (2007).

N. Kistaiah, C. Udaya Kiran, G. Ramachandra Reddy, and M. Sreenivasa Rao, J. Reinf. Plastics. Compos., 33, 1372 (2014).

O. Faruka, A. K. Bledzkia, H.-P. Finkb, and M. Saind, Progress Polym. Sci., 37, 1596 (2012).

M. R. Mansor, S. M. Sapuan, E. S. Zainudin, A. A. Nuraini, and A. Hambali, Mater. Des., 51, 492 (2013).

S. Dixit and P. Verma, Res. J. Chem. Sci., 2, 93 (2012).

X. Li, L. G. Tabil, and S. Panigrahi, J. Polym. Envir., 15, 33 (2007).

M. Jawaid and H. P. S. Abdul Khalil, Carb. Polym., 86, 18 (2011).

M. Idicula, S. K. Malhotra, K. Joseph, and S. Thomas, Compos. Sci. Technol., 65, 1087 (2005).

M. R. Sanjay, P. Madhu, M. Jawaid, P. Senthamaraikannan, S. Senthil, and S. Pradeep, J. Cleaner Prod., 172, 581 (2018).

S. D. Salman, Z. Leman, M. T. H. Sultan, M. R. Ishak, and F. Cardona, Int. J. Poly. Sci., 2016, 11 (2016).

B.-H. Lee, H.-J. Kim, and W.-R. Yu, Fiber. Polym., 10, 90 (2009).

H. Ku, H. Wang, N. Pattarachaiyakoop, and M. Trada, Compos. Part B: Eng., 42, 873 (2011).

D. Ray, B. K. Sarkar, A. K. Rana, and N. R. Bose, Bull. Mater. Sci., 24, 135 (2001).

S. Mishra, M. Misra, S. S. Tripathy, S. K. Nayak, and A. K. Mohanty, Macro. Mater. Eng., 286, 107 (2001).

A. Alawar, A. M. Hamed, and K. Al-Kaabi, Compos. Part B: Eng., 40, 606 (2009).

A. Bedjaoui, A. Belaadi, S. Amroune, and B. Madi, Int. J. Integ. Eng., 11, 17 (2019).

O. M. L. Asumani, R. G. Reid, and R. Paskaramoorthy, Compos. Part A: Appl. Sci. Manuf., 43, 1440 (2012).

V. Vilay, M. Mariatti, R. M. Taib, and M. Todo, Compos. Sci. Technol., 68, 638 (2008).

N. Venkateshwaran, A. Elaya Perumal, and D. Arunsundaranayagam, Mater. Des., 47, 159 (2013).

S. Kalia, B. S. Kaith, and I. Kaur, Polym. Eng. Sci., 49, 1272 (2009).

C. Dong, J. Reinf. Plas. Compos., 37, 348 (2018).

Y. Swolfs, L. Gorbatikh, and I. Verpoest, Appl. Sci. Manuf., 67, 200 (2014).

M. Boopalan, M. Niranjanaa, and M. J. Umapathy, Compos. Part B: Eng., 51, 57 (2013).

A. Alavudeen, N. Rajini, S. Karthikeyan, M. Thiruchitrambalam, and N. Venkateshwaren, Mater. Des., 66, 257 (2015).

A. V. Kiruthika, J. Build. Eng., 9, 99 (2017).

M. Ramesha, K. Palanikumarb, and K. Hemachandra Reddy, Ren. Sust. Energy Rev., 79, 584 (2017).

Y. Li, Y.-W. Mai, and L. Ye, Compos. Sci. Technol., 60, 2055 (2000).

A. Belaadi, M. Bourchak, and H. Aouici, Compos. Part B: Eng., 106, 153 (2016).

C. Baley, M. Gomina, J. Breard, A. Bourmaud, and P. Davies, Ind. Crops Prod., 145, 111984 (2020).

M. S. Rouhi, M. Juntikka, J. Landberg, and M. Wysocki, J. Reinf. Plastics, Compos., 38, 454 (2019).

M. Jawaid, H. P. S. Abdul Khalil, and A. Abu Bakar, Mater. Sci. Eng. A., 528, 5195 (2011).

ASTM D 790, American Society Test. Mater. Philadelphia, 8 (1998).

H. Aouici, M. A. Yallese, K. Chaoui, T. Mabrouki, and J.-F. Rigal, Measurement, 45, 353 (2012).

H. Aouici, M. Elbah, M. A. Yallese, B. Fnides, I. Meddour, and S. Benlahmidi, J. Adv. Manuf. Technol., 87, 2244 (2016).

T. Alsaeed, B. F. Yousif, and H. Ku, J. Prec. Technol., 3, 182 (2013).

A. V. R. Prasad and M. K. Rao, Mater. Des., 32, 4663 (2011).

R. M. N. Arib, S. M. Sapuan, M. M. H. M. Ahmad, M. T. Paridah, and H. M. D. Khairul Zaman, Mater. Des., 27, 396 (2006).

K. M. M. Rao, K. Mohana Rao, and A. V. Ratna Prasad, Mater. Des., 31, 513 (2010).

V. A. Alvarez and A. Vázquez, Compos. Part A: Appl. Sci. Manuf., 37, 1680 (2006).

L. F. Ng, S. D. Malingam, M. Z. Selamat, Z. Mustafa, and O. Bapokutty, Poly. Bull., 77, 1449 (2020).

A. Athijayamani, M. Thiruchitrambalam, U. Natarajan, and B. Pazhanivel, Polym. Compos., 31, 731 (2010).

K. J. Wong, S. Zahi, K. O. Low, and C. C. Lim, Mater. Des., 31, 4154 (2010).

H. Yang and R. Luo, Wear, 270, 681 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asma, B., Hamdi, L., Ali, B. et al. Flexural Mechanical Properties of Natural Fibre Reinforced Polymer Composites — A Statistical Investigation. Fibers Polym 21, 2321–2337 (2020). https://doi.org/10.1007/s12221-020-1299-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-1299-1