Abstract

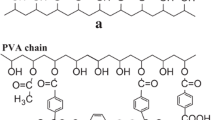

Natural rubber (NR) grafted with 2-ethylhexyl acrylate (2-EHA) and methacrylic acid (MAA, collectively NR-g-PEHA/MAA) was synthesized by emulsion polymerization. Tetraethylenepentamine and cumene hydroperoxide were used as redox initiators. The successful grafting of 2-EHA and MAA onto NR was confirmed by Fourier transform infrared spectroscopy. The morphology of the NR latex particles was observed by transmission electron microscopy. The effects of reaction temperature, initiator dosage, feeding mode, and hard monomer content on the mechanical properties of the modified NR film were investigated. Grafted polymer chains were unevenly wrapped on the outside of NR particles, and smaller particles were more easily grafted. Crosslinking was characterized using a toluene swelling method. Thermal stability and glass transition temperature were examined by differential scanning calorimetry and thermogravimetric analysis. The results showed that the thermal stability of NR-g-PEHA/MAA had been improved, and the glass transition temperature (Tg) was unchanged.

Similar content being viewed by others

References

Kohjiya S, Ikeda Y (2014) Chemistry, manufacture and applications of natural rubber. Woodhead Publishing, Elsevier, Sawston

Al-Ghamdi AA, Al-Hartomy OA, Al-Solamy FR et al (2016) Microwave properties of natural rubber based composites comprising conductive carbon black/silica hybrid fillers. J Polym Res 23(9):180

Pal K, Das T, Pal SK et al (2008) Use of carboxylated nitrile rubber and natural rubber blends as retreading compound for OTR tires. Polym Eng Sci 48(12):2410–2417

Murniati R, Sutisna Wibowo E et al (2017) Natural rubber nanocomposite as human-tissue-mimicking materials for replacement cadaver in medical surgical practice. Procedia Eng 170:101–107

Chen X, Wang ZF, Wu J (2018) Processing and characterization of natural rubber/stearic acid-tetra-needle-like zinc oxide whiskers medical antibacterial composites. J Polym Res 25(2):48

Karimi Shamsabadi M, Moghbeli MR (2017) Cellulose nanocrystals (CNCs) reinforced acrylic pressure-sensitive adhesives (PSAs) prepared via miniemulsion polymerization. Int J Adhes Adhes 78:155–166

Zhang XY, Liu HH, Yue LP et al (2019) Fabrication of acrylic pressure-sensitive adhesives containing maleimide for heat-resistant adhesive applications. Polym Bull 76(6):3093–3112

Xu CH, Cao LM, Lin BF et al (2016) Design of self-healing supramolecular rubbers by introducing ionic cross-links into natural rubber via a controlled vulcanization. ACS Appl Mater Interfaces 8(27):17728–17737

Heuwers B, Beckel A, Krieger A et al (2013) Shape-memory natural rubber: an exceptional material for strain and energy storage. Macromol Chem Phys 214(8):912–923

Sornsanee P, Jitprarop V, Tangboriboon N (2018) Preparation polyisoprene (NR) and polyacrylonitrile rubber latex glove films by dipping ceramic hand molds process and their properties. Defect Diffus Forum 382:21–25

Saetung A, Kaenhin L, Klinpituksa P et al (2012) Synthesis, characteristic, and properties of waterborne polyurethane based on natural rubber. J Appl Polym Sci 124(4):2742–2752

Kangwansupamonkon W, Gilbert RG, Kiatkamjornwong S (2005) Modification of natural rubber by grafting with hydrophilic vinyl monomers. Macromol Chem Phys 206(24):2450–2460

Chueangchayaphan W, Tanrattanakul V, Chueangchayaphan N et al (2017) Synthesis and thermal properties of natural rubber grafted with poly(2-hydroxyethyl acrylate). J Polym Res 24(7):107

Liu J, Tian XH, Sun JY et al (2016) Preparation of poly(methyl methacrylate-co-butyl methacrylate) nanoparticles and their reinforcing effect on natural rubber. J Appl Polym Sci 133(35):43843–43853. https://doi.org/10.1002/app.43843

Onyeagoro GN (2012) Preparation and characterization of natural rubber latex grafted with ethylacrylate (EA)–methylmethacrylate (MMA) monomers mixture. Acta Polym Sin 1(1):44–50

Jaimuang S, Vatanatham T, Limtrakul S et al (2015) Kinetic studies of styrene-grafted natural rubber emulsion copolymerization using transmission electron microscope and thermal gravimetric analysis. Polymer 67:249–257

Pukkate N, Yamamoto Y, Kawahara S (2008) Mechanism of graft copolymerization of styrene onto deproteinized natural rubber. Colloid Polym Sci 286(4):411–416

Jin W, Ke Z, Xin FU (2000) Study on natural rubber modified by grafting polyacrylates (EA/BA/AN/VAC). J Hebei Univ Sci Technol 21(4):61–65 (in Chinese)

Angnanon S, Prasassarakich P, Hinchiranan N (2011) Styrene/acrylonitrile graft natural rubber as compatibilizer in rubber blends. Polym Plast Technol Eng 50(11):1170–1178

Chueangchayaphan W, Chueangchayaphan N, Tanrattanakul V et al (2018) Influences of the grafting percentage of natural rubber-graft-poly(2-hydroxyethyl acrylate) on properties of its vulcanizates. Polym Int 67(6):739–746

Yimmut K, Homchoo K, Hinchiranan N (2018) Poly(butyl acrylate-co-fluorinated acrylate)-graft-natural rubber: synthesis and application as compatibilizer for natural rubber/poly(butyl acrylate-co-fluorinated acrylate) films. Colloids Surf A Physicochem Eng Aspects 540:11–22

Songsing K, Vatanatham T, Hansupalak N (2013) Kinetics and mechanism of grafting styrene onto natural rubber in emulsion polymerization using cumene hydroperoxide-tetraethylenepentamine as redox initiator. Eur Polym J 49(5):1007–1016

Wei FY (2014) Preparation and application of hydroxylethyl methacrylate grafted natural rubber latex. North University of China, Taiyuan (in Chinese)

Lee DY, Subramaniam N, Fellows CM et al (2002) Structure–property relationships in modified natural rubber latexes grafted with methyl methacrylate and vinylneo-decanoate. J Polym Sci A Polym Chem 40(7):809–822

Zhang QL, Tian XH, Sun JY et al (2017) Preparation of starch-g-PMMA, starch-g-P(MMA/BMA) and starch-g-P(MMA/MA) nanoparticles and their reinforcing effect on natural rubber by latex blending: a comparative study. Polym Sci Ser A 59(5):708–717

Dafader NC, Haque ME, Akhtar F et al (2006) Study on grafting of different types of acrylic monomers onto natural rubber by γ-rays. Radiat Phys Chem 75(1):168–172

Hossain K, Chowdhury AS (1970) Grafting of n-butyl acrylate with natural rubber latex film by gamma radiation: a reaction mechanism. Daffodil Int Univ J Sci Technol 5(1):81–88

Kochthongrasamee T, Prasassarakich P, Kiatkamjornwong S (2006) Effects of redox initiator on graft copolymerization of methyl methacrylate onto natural rubber. J Appl Polym Sci 101(4):2587–2601

Ragupathy L, Ziener U, Robert G et al (2011) Grafting polyacrylates on natural rubber latex by miniemulsion polymerization. Colloid Polym Sci 289(3):229–235

Nakason C, Kaesaman A, Yimwan N (2003) Preparation of graft copolymers from deproteinized and high ammonia concentrated natural rubber latices with methyl methacrylate. J Appl Polym Sci 87(1):68–75

Wang J, Zhang KY, Hao S et al (2019) Simultaneous reduction and surface functionalization of graphene oxide and the application for rubber composites. J Appl Polym Sci 136(15):47375

Liu C, Shao Y, Jia DM (2008) Chemically modified starch reinforced natural rubber composites. Polymer 49(8):2176–2181

Rao V, Johns J (2008) Mechanical properties of thermoplastic elastomeric blends of chitosan and natural rubber latex. J Appl Polym Sci 107(4):2217–2223

Sookyung U, Thitithammawong A, Nakason C et al (2018) Effects of cashew nut shell liquid and its decarboxylated form on the properties of natural rubber. J Polym Environ 26(8):1–7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Yao, F., Su, J. et al. Modification of Natural Rubber Latex by Graft Copolymerization of 2-Ethylhexyl Acrylate and Methacrylic Acid. Trans. Tianjin Univ. 26, 314–323 (2020). https://doi.org/10.1007/s12209-020-00254-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-020-00254-8