Abstract

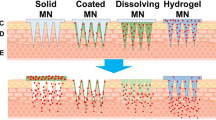

Hollow microneedles can penetrate the corneum of the skin and various biological barriers. Drugs can enter through a minimally invasive path or bodily fluid can be collected from the epidermis or dermis. This makes hollow microneedles (MN) a promising tool for drug delivery and body fluid sensing in a painless manner. Here, we propose a nickel microneedle with a length of 720 µm, an inner diameter of 27 µm, and an outer diameter of 87 µm. To construct the metal hollow microneedle model, we introduce three different manufacturing methods. The three methods are laser cutting, re-dissolution by SU-8 coating, and ultrasonic blade cutting. To verify the penetration capability, the microneedle array was tested to penetrate of the rabbit skin without rupture. The microneedle array was also repeatedly used in a film puncture experiment to verify the reliability of the structure. These microneedles can be combined with syringes and other drug delivery devices to achieve accurate quantitative and controllable flow rates of drug delivery. Through mechanical test and solution delivery test, we demonstrated that the microneedle structure has strong mechanical strength and a controllable rate of drug delivery, which is feasible as a drug delivery device.

Similar content being viewed by others

References

R. Ye et al., Fabrication of tip-hollow and tip-dissolvable microneedle arrays for transdermal drug delivery, ACS Biomater. Sci. Eng., 6 (2020) 2487–2494.

E. Larrañeta, R. E. M. Lutton, A. D. Woolfson and R. F. Donnelly, Microneedle arrays as transdermal and intradermal drug delivery systems: materials science, manufacture and commercial development, Mater. Sci. Eng. R Reports, 104 (2016) 1–32.

X. Zhang, Y. Wang, J. Chi and Y. Zhao, Smart microneedles for therapy and diagnosis, Research, 2020 (2020) 1–26.

B. H. Kim and Y. H. Seo, Transdermal drug delivery devices based on microneedles: a review, J. Mucopolysaccharidosis Rare Dis., 1 (2015) 5–14.

S. Henry, D. V. McAllister, M. G. Allen and M. R. Prausnitz, Microfabricated microneedles: a novel approach to transdermal drug delivery, J. Pharm. Sci., 87 (1998) 922–925.

M. R. Prausnitz, Microneedles for transdermal drug delivery, Adv. Drug Deliv. Rev., 56 (2004) 581–587.

J. Y. Lee et al., Highly flexible and porous silk fibroin microneedle wraps for perivascular drug delivery, J. Control. Release, 340 (2021) 125–135.

S. Pradeep Narayanan and S. Raghavan, Fabrication and characterization of gold-coated solid silicon microneedles with improved biocompatibility, Int. J. Adv. Manuf. Technol., 104 (2019) 3327–3333.

S. Mdanda, P. Ubanako, P. P. D. Kondiah, P. Kumar and Y. E. Choonara, Recent advances in microneedle platforms for transdermal drug delivery technologies, Polymers (Basel), 13 (2021).

E. Laszlo, G. De Crescenzo, A. Nieto-Argüello, X. Banquy and D. Brambilla, Superswelling microneedle arrays for dermal interstitial fluid (prote) omics, Adv. Funct. Mater, 31 (2021) 1–14.

Á. Cárcamo-Martínez et al., Hollow microneedles: A perspective in biomedical applications, Int. J. Pharm, 599 (2021).

Y. Mizuno et al., Fabrication of novel-shaped microneedles to overcome the disadvantages of solid microneedles for the transdermal delivery of insulin, Biomed. Microdevices, 23 (2021).

R. S. J. Ingrole and H. S. Gill, Microneedle coating methods: A review with a perspective, J. Pharmacol. Exp. Ther, 370 (2019) 555–569.

Y. Y. Hao et al., Effect of polymer microneedle pre-treatment on drug distributions in the skin in vivo, J. Drug Target, 28 (2020) 811–817.

R. R. Thakur Singh et al., Minimally invasive microneedles for ocular drug delivery, Expert Opin. Drug Deliv, 14 (2017) 525–537.

J. W. Lee and M. R. Prausnitz, Drug delivery using microneedle patches: not just for skin, Expert Opin. Drug Deliv, 15 (2018) 541–543.

J. H. Park, M. G. Allen and M. R. Prausnitz, Polymer microneedles for controlled-release drug delivery, Pharm. Res., 23 (2006) 1008–1019.

T. Miyano et al., Sugar micro needles as transdermic drug delivery system, Biomed. Microdevices, 7 (2005) 185–188.

J. Yang, X. Liu, Y. Fu and Y. Song, Recent advances of microneedles for biomedical applications: drug delivery and beyond, Acta Pharm. Sin. B, 9 (2019) 469–483.

J. Y. Tan, A. Kim and J. J. K. Kim, Fabrication and characterization of hollow microneedle array using diffraction UV lithography, 21st Int. Conf. Solid-State Sensors, Actuators Microsystems (Transducers) (2021) 1150–1153.

A. J. Guillot et al., Microneedle-based delivery: an overview of current applications and trends, Pharmaceutics, 12 (2020) 1–28.

T. Waghule et al., Microneedles: a smart approach and increasing potential for transdermal drug delivery system, Biomed. Pharmacother, 109 (2019) 1249–1258.

M. Gülçür et al., A cost-effective process chain for thermoplastic microneedle manufacture combining laser micromachining and micro-injection moulding, CIRP J. Manuf. Sci. Technol., 32 (2021) 311–321.

J. Wang, H. Wang, L. Lai and Y. Li, Preparation of microneedle array mold based on mems lithography technology, Micromachines, 12 (2021) 1–13.

Y. Li et al., Fabrication of sharp silicon hollow microneedles by deep-reactive ion etching towards minimally invasive diagnostics, Microsystems Nanoeng, 5 (2019).

S. Khumpuang, M. Horade, K. Fujioka and S. Sugiyama, Geometrical improvements of hollow microneedle fabrications by alignment X-ray lithography, Microsystem Technologies, 13 (3) (2007) 209–214.

W. Bai et al., Fabrication of metal micro needle array by LIGA process, Adv. Mater. Res., 418–420 (2012) 1911–1914.

Y. C. Kim, J. H. Park and M. R. Prausnitz, Microneedles for drug and vaccine delivery, Adv. Drug Deliv. Rev., 64 (2012) 1547–1568.

C. G. Li, C. Y. Lee, K. Lee and H. Jung, An optimized hollow microneedle for minimally invasive blood extraction, Biomed. Microdevices, 15 (2013) 17–25.

I. Mansoor, Y. Liu, U. O. Häfeli and B. Stoeber, Arrays of hollow out-of-plane microneedles made by metal electrodeposition onto solvent cast conductive polymer structures, J. Micromechanics Microengineering, 23 (2013).

P. Khanna, B. R. Flam, B. Osborn, J. A. Strom and S. Bhansali, Skin penetration and fracture strength testing of silicon dioxide microneedles, Sensors Actuators, A Phys., 170 (2011) 180–186.

A. Singh and S. Yadav, Microneedling: advances and widening horizons, Indian Dermatol. Online J., 7 (2016) 244.

G. Yan, K. S. Warner, J. Zhang, S. Sharma and B. K. Gale, Evaluation needle length and density of microneedle arrays in the pretreatment of skin for transdermal drug delivery, Int. J. Pharm, 391 (2010) 7–12.

K. Lee, H. C. Lee, D. S. Lee and H. Jung, Drawing lithography: Three-dimensional fabrication of an ultrahigh-aspect-ratio microneedle, Adv. Mater, 22 (2010) 483–486.

S. P. Davis, B. J. Landis, Z. H. Adams, M. G. Allen and M. R. Prausnitz, Insertion of microneedles into skin: measurement and prediction of insertion force and needle fracture force, J. Biomech, 37 (2004) 1155–1163.

L. G. Tran and W. T. Park, Rapid biodegradable microneedles with allergen reservoir for skin allergy test, Micro Nano Syst. Lett., 8 (2020).

Acknowledgments

This research was sponsored by the Seoul National University of Science and Technology internal research fund (Project number #2020-0570).

Author information

Authors and Affiliations

Corresponding author

Additional information

Chao-Wei Dong received his B.S. degree in Mechanical Engineering from Hannam University, Korea in 2018 and M.S. degree in Mechanical Engineering from Seoul National University of Science and Technology, Korea, in 2020. For his M.S. research, he worked on developing a micropump for medical applications. He is currently working toward the Ph.D. degree in Mechanical Engineering Department of Seoul National University of Science and Technology. His research interests include microscale package for guide wire and hollow microneedle for transdermal drug delivery.

Jong-Yeong Jeon is an undergraduate researcher of the Seoul National University of Science and Technology, Seoul, Korea. He received his B.S. degree in Mechanical Engineering from Seoul National University of Science and Technology, Korea in 2022. His research interests include hollow microneedle for transdermal drug delivery.

Hye-Min Kang is an undergraduate researcher of the Seoul National University of Science and Technology. She received her B.S. degree in Mechanical Engineering graduate from Seoul National University of Science and Technology, Korea in 2022. Her research interests include semiconductor and micromedical equipment.

Woo-Tae Park received the B.S. degree in mechanical design from Sungkyunkwan University, Korea, in 2000, the M.S. and Ph.D. degrees in mechanical engineering from Stanford University in 2002 and 2006 respectively. For his Ph.D., he worked on wafer scale encapsulated MEMS devices for biomedical applications. After graduation, he worked at Intel Corporation, Freescale Semiconductor, and IME Singapore, leading several projects on MEMS development. He has authored more than 80 journals and refereed conference papers and has 14 issued and pending patents. He is currently an Associate Professor at Seoul National University of Science and Technology, conducting research on microscale medical devices.

Rights and permissions

About this article

Cite this article

Dong, CW., Jeon, JY., Kang, HM. et al. Tip fabrication methods of hollow metal microneedles. J Mech Sci Technol 37, 261–269 (2023). https://doi.org/10.1007/s12206-022-1226-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-1226-z