Abstract

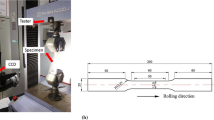

The AA7075-T6 sheet recently received attention, owing to its low weight and strength for use fabricating automotive parts (e.g., body, motor case). Owing to its low ductility and high strength at room temperature, it is difficult to form; a heating process is required. In this paper we investigate the mechanical properties of a 1.0-mm-thick AA7075-T6 sheet at different temperatures via an uniaxial tensile test, examining the forming characteristics of incremental sheet forming (ISF) at different temperatures. In the ISF experiment, a sheet clamped on a fixed die was heated and maintained at the designed temperature. The forming force was measured by an in situ force monitoring system. The forming parameters included tool diameter, vertical step, temperature, and feed speed. Vertical step and temperature were selected at three levels for experimental design. The formability was evaluated by varying the shapes of wall-angle conical frustums. When the temperature increased to 200 °C, the formability increased dramatically. The fracture-forming limit curve in ISF was defined for this material at different temperatures. This fracture criterion was loaded into ABAQUS software to predict fracture. The comparison between experimental and finite-element method simulation shows good agreement.

Similar content being viewed by others

References

H. Iseki, K. Kato and S. Sakamoto, Flexible and incremental sheet metal bulging using a path-controlled spherical roller, Transactions of the Japan Society of Mechanical Engineers Series C, 504 (58) (1992) 3147–3155.

M. Ham and J. Jeswiet, Single point incremental forming and forming criteria for AA3003, CIRP Annals - Manufacturing Technology, 55 (1) (2006) 241–244.

A. Bhattacharya, K. Maneesh, N. Venkata and J. Cao, Formability and surface finish studies in single point incremental forming, Journal of Manufacturing Science and Engineering, 133 (6) (2011).

T. Obikawa, T. Hakutani, T. Sekine, S. Numajiri, T. Matsumura and M. Yoshino, Single-point incremental microforming of thin shell products utilizing high formability, Journal of Advanced Mechanical Design, Systems, and Manufacturing, 6 (4) (2010) 1145–1156.

J. Cao and R. Malhotra, System and method for accumulative double sided incremental forming, US Patent, 9168580B2 (2015).

T. H. D. Nguyen, H. S. Oh, S. T. Hong, H. N. Han and J. Cao, A review of electrically-assisted manufacturing, International Journal of Precision Engineering and Manufacturing- Green Technology, 2 (4) (2015) 365–376.

M. Durante, A. Formisano, A. Langella and M. C. Minutolo, The influence of tool rotation on an incremental forming process, Journal of Materials Processing Technology, 209 (9) (2009) 4621–4626.

J. Wang, L. H. Li and H. S. Jiang, Effects of forming parameters on temperature in frictional stir incremental sheet forming, Journal of Mechanical Science and Technology, 30 (5) (2016) 2163–2169.

M. S. Mohamed, A. D. Foster, J. G. Lin, D. S. Balint and T. A. Dean, Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling, International Journal of Machine Tools and Manufacture, 53 (1) (2012) 27–38.

H. Wang, Y. B. Luo, P. Friedman, M. H. Chen and L. Gao, Warm forming behavior of high strength aluminum alloy AA7075, Transactions of Nonferrous Metals Society of China, 22 (1) (2012) 1–7.

W. C. Xiao, B. Y. Wang, Y. Kang, W. P. Ma and X. F. Tang, Deep drawing of aluminum alloy 7075 using hot stamping, Rare Metals, 36 (6) (2017) 485–493.

Q. T. Pham, B. H. Lee, K. C. Park and Y. S. Kim, Influence of the post-necking prediction of hardening law on the theoretical forming limit curve of aluminium sheets, International Journal of Mechanical Science, 140 (2018) 521–536.

J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou and J. Allwood, Asymmetric single point incremental forming of sheet metal, CIRP Annals — Manufacturing Technology, 54 (2) (2005) 88–114.

D. Young and J. Jeswiet, Forming limit diagrams for single point incremental forming of aluminum sheet, Proc. of the Institution of Mechanical Engineers Part B: Journal of Engineering Manufacture, 4 (219) (2005) 359–364.

M. Durante, A. Formisano and A. Langella, Observations on the influence of tool-sheet contact conditions on an incremental forming process, Journal of Materials Engineering and Performance, 20 (6) (2011) 941–946.

G. Hussain, N. Hayat and L. Gao, Pyramid as test geometry to evaluate formability in incremental forming: Recent results, Journal of Mechanical Science and Technology, 26 (8) (2012) 2337–2345.

M. B. Silva, K. Isik, A. E. Tekkaya and P. A. F. Martins, Fracture loci in sheet metal forming: a review, Acta Metallurgica Sinica, 28 (12) (2015) 1415–1425.

V. C. Do, Q. T. Pham and Y. S. Kim, Identification of forming limit curve at fracture in incremental sheet forming, International Journal of Advanced Manufacturing Technology, 92 (9-12) (2017) 4445–4455.

Acknowledgments

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2017R1A6 A3A11030503). In addition, this work was partly supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the republic of Korea (grant No. 20155000000100).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Maenghyo Cho.

Xiao Xiao is a Ph.D. student at Kyungpook National University, Republic of Korea. He received his Master degree at Kyungpook National University, Korea in 2017. His research interests are plasticity, sheet metal forming and FEM.

Young-Suk Kim received his M.S. degrees from the Department of Mechanical Engineering at Seoul National University in 1981. He obtained his Ph.D. degree from the Department of Mechanical Engineering at Kobe University in 1986. He is currently a Professor in the Department of Mechanical Engineering at Kyungpook National University. His research interests are production engineering, plasticity, nano / micromechanics, FEM and biomechanics.

Rights and permissions

About this article

Cite this article

Xiao, X., Kim, CI., Lv, XD. et al. Formability and forming force in incremental sheet forming of AA7075-T6 at different temperatures. J Mech Sci Technol 33, 3795–3802 (2019). https://doi.org/10.1007/s12206-019-0722-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0722-2