Abstract

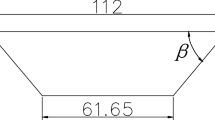

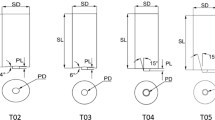

Frictional stir Incremental sheet forming (ISF) is a new technology used to fabricate parts of hard-to-form materials without using heating equipment. Thus far, limited information is known about the effects of main forming parameters, except spindle speed of the tool, on the temperature of formed sheet in friction-stir ISF. The effects of six forming parameters, namely, sheet thickness, tool vertical step, tool diameter, spindle speed, feed rate, and wall angle of the formed part, were identified using the design of experiment of orthogonal array, analysis of response tables and graphs, and analysis of variance. Results show that spindle speed, feed rate, sheet thickness, and tool vertical step significantly affect the temperature of the sheet. In addition, the temperature of the sheet is significantly increased by increasing sheet thickness, tool vertical step, and spindle speed but significantly decreased with increasing tool feed rate.

Similar content being viewed by others

References

J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou and J. Allwood, Asymmetric single point incremental forming of sheet metal, CIRP Annals -Manufacturing Technology, 54 (2) (2005) 88–114.

S. B. M. Echrif and M. Hrairi, Research and progress in incremental sheet forming processes, Materials and Manufacturing Processes, 26 (11) (2011) 1404–1414.

S. Golabi and H. Khazaali, Determining frustum depth of 304 stainless steel plates with various diameters and thicknesses by incremental forming, Journal of Mechanical Science and Technology, 28 (8) (2014) 3273–3278.

G. Hussain, N. Hayat and G. Lin, Pyramid as test geometry to evaluate formability in incremental forming: Recent results, Journal of Mechanical Science and Technology, 26 (8) (2012) 2337–2345.

G. Ambrogio, L. Filice and F. Gagliardi, Formability of lightweight alloys by hot incremental sheet forming, Materials and Design, 34 (2012) 501–508.

J. R. Duflou, B. Callebaut, J. Verbert and H. De Baerdemaeker, Laser assisted incremental forming: Formability and accuracy improvement, CIRP Annals -Manufacturing Technology, 56 (1) (2007) 273–276.

S. W. Kim, Y. S. Lee, S. H. Kang and J. H. Lee, Incremental forming of Mg alloy sheet at elevated temperatures, Journal of Mechanical Science and Technology, 21 (10) (2007) 1518–1522.

G. Ambrogio, L. Filice and G. Manco, Warm incremental forming of magnesium alloy AZ31, CIRP Annals -Manufacturing Technology, 57 (1) (2008) 257–260.

G. Fan, L. Gao, G. Hussain and Z. Wu, Electric hot incremental forming: A novel technique, International Journal of Machine Tools and Manufacture, 48 (15) (2008) 1688–1692.

D. K. Xu, W. C. Wu, R. Malhotra, J. Chen, B. Lu and J. Cao, Mechanism investigation for the influence of tool rotation and laser surface texturing (LST) on formability in single point incremental forming, International Journal of Machine Tools and Manufacture, 73 (2013) 37–46.

G. Buffa, D. Campanella and L. Fratini, On the improvement of material formability in SPIF operation through tool stirring action, International Journal of Advanced Manufacturing Technology, 66 (9-12) (2013) 1343–1351.

J. Park, J. Kim, N. Park and Y. Kim, Study of forming limit for rotational incremental sheet forming of magnesium alloy sheet, Metallurgical and Materials Transactions A, 41 (1) (2010) 97–105.

J. G. Park, B. S. You and Y. S. Kim, A parameter study in incremental forming of magnesium alloy sheet, Transations of Materials Processing, 17 (6) (2008) 412–419 (in Korean).

M. Otsu, H. Matsuo, M. Matsuda and K. Takashima, Friction stir incremental forming of aluminum alloy sheets, Steel Research International, 81 (9) (2010) 942–945.

M. Otsu, T. Ichikawa, M. Matsuda and K. Takashima, Improvement of formability of magnesium alloy sheets by friction stir incremental forming, Proc. of the 10th International Conference on Technology of Plasticity, Aachen, Germany (2011) 537–541.

J. Wang, L. Song, L. Li and H. Jiang, Numerical simulation research on sheet temperature rise of rolling incremental sheet forming, Hot Working Technology, 44 (23) (2015) 133–136 (in Chinese).

L. Song, J. Wang, L. Li, H. Wang and G. Wang, Numerical simulation of temperature field distribution for RISF, Forging and Stamping Technology, 39 (7) (2014) 138–143 (in Chinese).

H. Wang, J. Wang, T. Wang, L. Li and H. Jiang, Experimental research on process parameters of magnesium alloy in rotational incremental sheet forming, Forging and Stamping Technology, 40 (7) (2015) 48–52 (in Chinese).

H. Yang and M. Zhan, Modeling Method for Experiments of Materials Processing, Northwestern Polytechnical University Press, Xi’an, China (2008) (in Chinese).

D. Xu, B. Lu, T. Cao, J. Chen, H. Long and J. Cao, A comparative study on process potentials for frictional stir-and electric hot-assisted incremental sheet forming, Procedia Engineering, 81 (2014) 2324–2329.

R. Aerens, P. Eyckens, A. Van Bael and J. R. Duflou, Force prediction for single point incremental forming deduced from experimental and FEM observations, The International Journal of Advanced Manufacturing Technology, 46 (9-12) (2009) 969–982.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Cheol Ko

Jin Wang received his B.Sc. degree in 2000 and M.Sc. degree in 2003 from Xi’an University of Architecture and Technology and his Ph.D. in 2007 from Shanghai Jiaotong University in China. He joined the School of Mechanical Engineering in Qingdao Technological University in China in 2007 and is currently Associate Professor of Mechanical Engineering. His profession and interests are incremental sheet forming, numerical simulation for metal forming, and severe plastic deformation.

Rights and permissions

About this article

Cite this article

Wang, J., Li, L. & Jiang, H. Effects of forming parameters on temperature in frictional stir incremental sheet forming. J Mech Sci Technol 30, 2163–2169 (2016). https://doi.org/10.1007/s12206-016-0423-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0423-z