Abstract

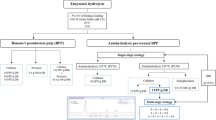

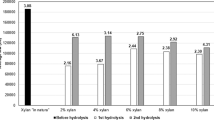

This study proposes the use of banana pseudostem and leaves and guava bagasse, waste generated in excess in fruit growing, for the production of cello-oligosaccharides (COS), compounds of industrial interest with potential health benefits. The objective was to reduce the recalcitrance of these biomasses through physical and chemical processes. Initially, all biomasses (untreated and chemically pretreated with sulfuric acid, hydrogen peroxide, sodium, and potassium hydroxide) were subjected to the action of endoglucanase enzyme (20, 50, and 100 IU/g) to determine the optimal condition. Subsequently, the biomasses were hydrolyzed with 30 IU/g of endoxylanase for 24 h and 20 IU/g of endoglucanase for 6 h. The second stage was carried out under the same conditions mentioned earlier but with the biomasses previously ground in a ball mill. The highest cellulose to COS conversion was 79.73%, achieved from banana leaves, with 20% sodium hydroxide (w/w) at 121 °C/30 min, ball milled, and hydrolyzed with xylanase and endoglucanase. The highest COS yields for banana pseudostem and guava bagasse were 53.05% and 59.99%, respectively, using alkali. The removal of xylan leads to more accessibility of cellulose to endoglucanase action. In addition to obtaining COS, xylooligosaccharides (XOS) were also produced in this process, both with the potential for industrial applications, mainly due to their prebiotic action. In general, the best results were obtained with alkaline pretreatments and always with endoxylanase before endoglucanase. Ball milling was beneficial only for materials pretreated with sulfuric acid and sodium hydroxide.

Similar content being viewed by others

Data Availability

The data of this study are available on request from the corresponding author.

References

Kendrick EG, Bhatia R, Barbosa FC et al (2022) Enzymatic generation of short chain cello-oligosaccharides from Miscanthus using different pretreatments. Bioresour Technol 358:127399. https://doi.org/10.1016/j.biortech.2022.127399

Precup G, Venus J, Heiermann M et al (2022) Chemical and enzymatic synthesis of biobased xylo-oligosaccharides and fermentable sugars from wheat straw for food applications. Polym 14:1336. https://doi.org/10.3390/polym14071336

de Freitas C, Terrone CC, Forsan CF et al (2022) Oligosaccharides from lignocellulosic biomass and their biological and physicochemical properties. In: Brienzo M (ed) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Springer Nature, Singapore, pp 275–309

de Figueiredo FC, de Oliva-Neto P (2022) Advances and new perspectives in prebiotic, probiotic and symbiotic products for food nutrition and feed. In: Brienzo M (ed) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Springer Nature, Singapore, pp 311–336

Jana UK, Kango N, Pletschke B (2021) Hemicellulose-derived oligosaccharides: emerging prebiotics in disease alleviation. Front Nutr 8:670817. https://doi.org/10.3389/fnut.2021.670817

Zhong C, Ukowitz C, Domig KJ, Nidetzky B (2020) Short-chain cello-oligosaccharides: intensification and scale-up of their enzymatic production and selective growth promotion among probiotic bacteria. J Agric Food Chem 68:8557–8567. https://doi.org/10.1021/acs.jafc.0c02660

Ávila PF, Silva MF, Martins M, Goldbeck R (2021) Cello-oligosaccharides production from lignocellulosic biomass and their emerging prebiotic applications. World J Microbiol Biotechnol 37:73. https://doi.org/10.1007/s11274-021-03041-2

Forsan CF, Schmatz A, Masarin F, Brienzo M (2022) Xylooligosaccharide production by optimized sulfuric, acetic acid, and liquid hot water treatment of sugarcane leaves. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-03316-0

Yan F et al (2022) Preparation and nutritional properties of xylooligosaccharide from agricultural and forestry byproducts: a comprehensive review. Front Nutr 9:977548

Pereira BS, de Freitas C, Contiero J, Brienzo M (2022) Enzymatic production of xylooligosaccharides from xylan solubilized from food and agroindustrial waste. Bioenerg Res 15:1195–1203. https://doi.org/10.1007/s12155-021-10373-2

Pereira BS, de Freitas C, Vieira RM, Brienzo M (2022) Brazilian banana, guava, and orange fruit and waste production as a potential biorefinery feedstock. J Mater Cycles Waste Manag 24:2126–2140. https://doi.org/10.1007/s10163-022-01495-6

SEBRAE (2023) Brasil é o 4º produtor mundial de banana. https://sebrae.com.br/sites/PortalSebrae/artigos/brasil-e-o-4-produtor-mundial-de-banana,1f00286bf0837810VgnVCM1000001b00320aRCRD.

Redondo-Gómez C, Rodríguez Quesada M, Vallejo Astúa S et al (2020) Biorefinery of biomass of agro-industrial banana waste to obtain high-value biopolymers. Molecules 25:3829. https://doi.org/10.3390/molecules25173829

Kumar M, Kapoor S, Dhumal S et al (2022) Guava (Psidium guajava L.) seed: a low-volume, high-value byproduct for human health and the food industry. Food Chem 386:132694. https://doi.org/10.1016/j.foodchem.2022.132694

Melati RB, Shimizu FL, Oliveira G et al (2019) Key factors affecting the recalcitrance and conversion process of biomass. Bioenerg Res 12:1–20. https://doi.org/10.1007/s12155-018-9941-0

Shimizu FL, de Azevedo GO, Coelho LF et al (2020) Minimum lignin and xylan removal to improve cellulose accessibility. Bioenerg Res 13:775–785. https://doi.org/10.1007/s12155-020-10120-z

Kundu C, Samudrala SP, Kibria MA, Bhattacharya S (2021) One-step peracetic acid pretreatment of hardwood and softwood biomass for platform chemicals production. Sci Rep 11:11183. https://doi.org/10.1038/s41598-021-90667-9

Zhao X, Qi Y, Xu J, Liu D, Chen X, Huang Q (2020) Enhanced enzymatic saccharification of lignocellulose by mechanically pretreating the substrate. Biotechnol Biofuels 13:1. https://doi.org/10.1186/s13068-020-01712-5

Kumar M, Xiong X, Wan Z et al (2020) Ball milling as a mechanochemical technology for fabrication of novel biochar nanomaterials. Bioresour Technol 312:123613. https://doi.org/10.1016/j.biortech.2020.123613

Barbosa FC, Martins M, Brenelli LB et al (2020) Screening of potential endoglucanases, hydrolysis conditions and different sugarcane straws pretreatments for cello-oligosaccharides production. Bioresour Technol 316:123918. https://doi.org/10.1016/j.biortech.2020.123918

Sinha T, Sharma K, Yazdani SS (2023) Cellobiohydrolases. In: Arun G, Kedar S (eds) Glycoside Hydrolases. Elsevier, pp 77–95

Arsat N, Ghazali NF (2023) Immobilization of β-glucosidase on polyethersulfone membrane for cellobiose hydrolysis. Materials Today: Proceedings S2214785323046874. https://doi.org/10.1016/j.matpr.2023.09.027

Ejaz U, Sohail M, Ghanemi A (2021) Cellulases: from bioactivity to a variety of industrial applications. Biomimetics 6:44. https://doi.org/10.3390/biomimetics6030044

Rosgaard L, Pedersen S, Langston J et al (2007) Evaluation of minimal Trichoderma reesei cellulase mixtures on differently pretreated barley straw substrates. Biotechnol Prog 23:1270–1276. https://doi.org/10.1021/bp070329p

Karnaouri A, Matsakas L, Krikigianni E et al (2019) Valorization of waste forest biomass toward the production of cello-oligosaccharides with potential prebiotic activity by utilizing customized enzyme cocktails. Biotechnol Biofuels 12:285. https://doi.org/10.1186/s13068-019-1628-z

Zhang R, Hu Z, Peng H et al (2023) High density cellulose nanofibril assembly leads to upgraded enzymatic and chemical catalysis of fermentable sugars, cellulose nanocrystals and cellulase production by precisely engineering cellulose synthase complexes. Green Chem 25:1096–1106. https://doi.org/10.1039/D2GC03744K

Phirom-on K, Apiraksakorn J (2021) Development of cellulose-based prebiotic fiber from banana peel by enzymatic hydrolysis. Food Biosci 41:101083. https://doi.org/10.1016/j.fbio.2021.101083

Díaz S, Ortega Z, Benítez AN et al (2021) Oligosaccharides production by enzymatic hydrolysis of banana pseudostem pulp. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-02033-4

Fernandes ÉS, Bueno D, Pagnocca FC, Brienzo M (2020) Minor biomass particle size for an efficient cellulose accessibility and enzymatic hydrolysis. ChemistrySelect 5:7627–7631. https://doi.org/10.1002/slct.202001008

Sluiter JB, Ruiz RO, Scarlata CJ et al (2010) Compositional analysis of lignocellulosic feedstocks. 1. Review and description of methods. J Agric Food Chem 58:9043–9053. https://doi.org/10.1021/jf1008023

Shimizu FL, Monteiro PQ, Ghiraldi PHC et al (2018) Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind Crop and Prod 115:62–68. https://doi.org/10.1016/j.indcrop.2018.02.024

Brienzo M, Abud Y, Ferreira S et al (2016) Characterization of anatomy, lignin distribution, and response to pretreatments of sugarcane culm node and internode. Ind Crop Prod 84:305–313. https://doi.org/10.1016/j.indcrop.2016.01.039

Melati RB, Sass DC, Contiero J, Brienzo M (2023) Xylan solubilization from partially delignified biomass, and residual lignin removal from solubilized xylan. Polysaccharides 4:176–188. https://doi.org/10.3390/polysaccharides4020013

Brienzo M, Siqueira AF, Milagres AMF (2009) Search for optimum conditions of sugarcane bagasse hemicellulose extraction. Biochem Eng J 46:199–204. https://doi.org/10.1016/j.bej.2009.05.012

Alves RC, Melati RB, Casagrande GM et al (2021) Sieving process selects sugarcane bagasse with lower recalcitrance to xylan solubilization. J Chem Technol Biotechnol 96:327–334. https://doi.org/10.1002/jctb.6541. (atividade endoglucanase)

Tareen AK, Punsuvon V, Parakulsuksatid P (2020) Investigation of alkaline hydrogen peroxide pretreatment to enhance enzymatic hydrolysis and phenolic compounds of oil palm trunk. 3 Biotech 10:179. https://doi.org/10.1007/s13205-020-02169-6

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270. https://doi.org/10.1016/0168-1656(92)90074-J

de Freitas C, Terrone CC, Masarin F et al (2021) In vitro study of the effect of xylooligosaccharides obtained from banana pseudostem xylan by enzymatic hydrolysis on probiotic bacteria. Biocatal Agric Biotechnol 33:101973. https://doi.org/10.1016/j.bcab.2021.101973

Schmatz AA, Masarin F, Brienzo M (2022) Lignin removal and cellulose digestibility improved by adding antioxidants and surfactants to organosolv pretreatment of sugarcane bagasse. Bioenerg Res 15:1107–1115. https://doi.org/10.1007/s12155-021-10367-0

Forsan CF, Paz Cedeño FR, Masarin F, Brienzo M (2021) Xylooligosaccharides production by optimized autohydrolysis, sulfuric and acetic acid hydrolysis for minimum sugar degradation production. Bioact Carbohydr Diet Fibre 26:100268. https://doi.org/10.1016/j.bcdf.2021.100268

de Freitas C, Brienzo M (2022) Enzymatic hydrolysis applied to banana pseudostem biomass compared to solubilized xylan for xylooligosaccharides production with high substrate concentration. Bioenerg Res. https://doi.org/10.1007/s12155-022-10508-z

Li K, Fu S, Zhan H et al (2010) Analysis of the chemical composition and morphological structure of banana psudo-stem. Bioresour 5:576–585

Fernandes ERK, Marangoni C, Souza O, Sellin N (2013) Thermochemical characterization of banana leaves as a potential energy source. Energy Convers and Manag 75:603–608. https://doi.org/10.1016/j.enconman.2013.08.008

Tarrés Q, Espinosa E, Domínguez-Robles J et al (2017) The suitability of banana leaf residue as raw material for the production of high lignin content micro/nano fibers: from residue to value-added products. Ind Crop Prod 99:27–33. https://doi.org/10.1016/j.indcrop.2017.01.021

Oliveira L, Cordeiro N, Evtuguin DV et al (2007) Chemical composition of different morphological parts from ‘Dwarf Cavendish’ banana plant and their potential as a non-wood renewable source of natural products. Ind Crop Prod 26:163–172. https://doi.org/10.1016/j.indcrop.2007.03.002

Camarena-Tello JC, Rocha-Guzmán NE, Gallegos-Infante JA, et al (2015) Chemical composition of biomass generated in the guava tree pruning. EXCLI J 14:204-12; ISSN 1611–2156. https://doi.org/10.17179/EXCLI2014-467

Brienzo M, Fikizolo S, Benjamin Y et al (2017) Influence of pretreatment severity on structural changes, lignin content and enzymatic hydrolysis of sugarcane bagasse samples. Renew Energ 104:271–280. https://doi.org/10.1016/j.renene.2016.12.037

Acknowledgements

The authors are grateful to the Brazilian Improvement Coordination of Higher Education Personnel (CAPES), Brazilian National Council for Scientific and Technological Development (process number 303039/2021-2), and São Paulo Research Foundation (FAPESP, process number 2017/22401-8) for its financial support.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Carolina Froes Forsan and Michel Brienzo. Caroline de Freitas reviewed the material. The first draft of the manuscript was written by Carolina Froes Forsan and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Neither humans nor animals were used to perform the study reported by this manuscript.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Forsan, C.F., de Freitas, C. & Brienzo, M. Cello-oligosaccharides and Xylooligosaccharides Production by a Combination of Mechanical, Chemical, and Enzymatic Treatments of Banana Pseudostem and Leaves and Guava Bagasse. Bioenerg. Res. 17, 129–144 (2024). https://doi.org/10.1007/s12155-023-10688-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10688-2