Abstract

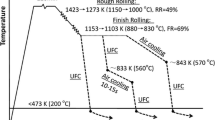

The effect of warm forging in the inter-critical temperature range between 705 and 844°C, in improving the impact toughness of an industrially important micro alloyed steel, 38MnSiVS6 was investigated. The impact properties were enhanced to as high as 148 J after warm forging in the inter critical range, as against 19 J in the steel hot rolled from 1200°C and air cooled. In addition, the strength was enhanced by about 100 MPa after warm forging. The microstructure evolution that led to the improved toughness and strength was analyzed. The significantly enhanced toughness with moderate strength enhancement in warm deformation is attributed to the increases in the ferrite content, finer ferrite grain size, finer pearlite colonies and finer interlamellar spacing. The fractography of the impact test samples in hot deformed and air-cooled condition shows poor toughness associated with cleavage facets, while the warm forged steel, showed fine dimple rupture.

Similar content being viewed by others

References

Jahazi M and Eghbali B 2001 The influence of hot forging conditions on the microstructure and mechanical properties of two microalloyed steels. Journal of Materials Processing Technology 113(1–3): 594–598

Matlock D K, Krauss G and Speer J G 2005 New microalloyed steel applications for the automotive sector. In: Materials Science Forum Trans. Tech. Publications Ltd, 500–501: 87–96

Zajac S, Siwecki T and W B H and Lagneborg R, 1998 Strengthening mechanisms in vanadium microalloyed steels intended for long products. ISIJinternational 38(10): 1130–1139

Ceschini L, Marconi A, Martini C, Morri A and Di Schino A 2013 Tensile and impact behaviour of a microalloyed medium carbon steel: effect of the cooling condition and corresponding microstructure. Materials and Design 45: 171–178

Yu L and Milbourn D J 2013 Vanadium Microalloyed Forging Steel: In: Proceeding of the 2nd International Symposium on Automobile Steel Anshan, China:47-54

Penalba F, Cars F M, Garcia de Andres C, Zapirain F and De Andres M P 1992 Characteristics of Vanadium and Titanium Microalloyed Steels Forged at Intermediate Warm Temperatures through Simulation by Torsion. ISIJ Int. 32(2): 232–240

Song R, Ponge D and Raabe D 2005 Mechanical properties of an ultrafine grained C-Mn steel processed by warm deformation and annealing. Acta Materialia 53(18): 4881–4892

Zhao P and Boyd J D 2007 Strengthening and fracture mechanisms in warm forged microalloyed medium carbon steel. Mat. Sci. and Tech. 23(10): 1186–1194

Eghbali B 2010 Study on the ferrite grain refinement during intercritical deformation of a microalloyed steel. Mat. Sci. and Eng. A 527(15): 3407–3410

Caminagaa C, BottaFilhob W J, Silva M L N and Buttona S T 2011 Strengthening Mechanisms of 27MnSiVS6 Microalloyed Steel Deformed by Four Different Forging Processes. Procedia Engineering 10: 512–517

Majta J and Bator A 2002 Mechanical behavior of hot and warm formed microalloyed steel. JMPT 125–126: 77–83

Carlos G M, Beatriz L, Jose M and Rodriguez I 2011 Warm forged V microalloyed steel. J. Iron and steel Research International 18(Sup. 1–2): 822–826

Spena P R and Firrao D 2013 Thermomechanical warm forging of Ti–V, Ti–Nb, and Ti–B microalloyed medium carbon steels. Mat. Sci. and Eng. 560: 208–215

Shena X J, Tanga S and Wu Y J 2017 Evolution of microstructure and crystallographic texture of microalloyed steel during warm rolling in dual phase region and their influence on mechanical properties, Mat. Sci. and Eng.,A, 685: 194–204

Balachandran G, Menaka K and Ravichandar D 2019 Influence of Manganese and Boron Alloying and Processing Conditions on the Microstructure and the Mechanical Properties of 0.4% Carbon Steels. Trans. Indian Inst. of Met. 72(2): 401–409

Karthick R, Balachandran G and Ravichandar D 2019 Microstructure and Mechanical Properties in Warm Forged 27MnSiVS6 Microalloyed Steel. Trans. Indian Inst. Met. 72(2): 411–421

Lagneborg R and Zajac S 2001 A model for interphase precipitation in V-microalloyed structural steels. Metallurgical and Materials Transactions A 32(1): 39–50

Lagneborg R, Siwecki S, Zajac T and Hutchinson B 1999 The Role of Vanadium in Microalloyed Steels. Scand. J. Metall. 28(5): 186–241

Maa Ferreira de Olivei 2004 Jorge Jr A M, and Balancin O 2004 Influence of Deformation on the Kinetics of Phase Transformation in a Forging Steel During Warm Working. Material Research 7(2): 247–253

Saito Y 1987 Mathematical Model of Hot Deformation Resistance in Austenite-Ferrite Two Phase Region. Trans. ISIJ Int. 27(6): 419–424

Kawulok R, Schindler I, Kawulok P, Rusz S, Opěla P, Kliber J, Solowski Z, Čmiel K M, Podolínský Malis M, Vasek Z and Vancura F 2016 Transformation kinetics of selected steel grades after plastic deformation. Metalurgija 55(3): 357–360

Kawulok R, Schindler I, Kawulok P, Rusz S, Opěla P, Kliber J, Solowski Z and Čmiel Podolínský K M 2018 Transformation Diagrams of Selected Steel Grades with Consideration of Deformation Effect. Arch. Metall. Mater. 63(1): 55–60

Takada H and Koyasu Y 1995 Present status and Future outlook of micro alloyed steels, Nippon Steel Tech. Report No.64 :7

Marion C, Ponge D and Raabe D 2010 Effect of grain refinement to 1 μm on strength and toughness of dual-phase steels. Mat. Sci. and Eng. A 527(29–30): 7832–7840

Tamura I, Sekine H, Tanaka T and Ouchi C 1988 Thermomechanical Processing of High-strength Low-alloy Steels, Butterworths Pub Co:101-105

Lee R S and Jou J L 2003 Application of numerical simulation for wear analysis of warm forging die. Journal of Materials Processing Technology 140(1–3): 43–48

Korchynsky M and Paules J R 1989 Microalloyed Forging Steels:A State-of-the-Art Review, SAE Transactions 98: 726–736

Acknowledgements

The authors wish to thank their colleagues of Quality Assurance Department for all the support. The authors also thank the JSW Steel Limited Salem Works for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gobinath, R., Vidhyasagar, M., Kumar, N.N. et al. Enhancement of impact toughness on warm forged microalloyed steel-38MnSiVS6. Sādhanā 46, 118 (2021). https://doi.org/10.1007/s12046-021-01638-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01638-9