Abstract

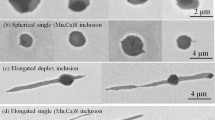

Oxygen is an important element for improving the sulfide morphology in steels that require machinability. Therefore, 50 ppm oxygen was added to 1215MS free-cutting steel under industrial conditions; the effect of oxygen on sulfide morphology and the formation mechanism of three types of sulfides were explored. The precipitation temperature of sulfide in steel at equilibrium state is 1489.98°C; oxygen can dissolve in MnS to form spherical single-particle Mn(S,O). Annular polycrystalline Mn(S,O) with a diameter of 10 μm was observed by characterization of scanning electron microscopy and electron backscatter diffraction (SEM and EBSD). It is formed by three stages of contact, sintering and densification. Sintering force is a vital force in the formation of polycrystalline Mn(S,O). Mn(S,O)-MOx(M = Si,Al,Mn,Fe) composite inclusion is formed by a liquid inclusion, (Mn,Si,Al,Fe)x(O,S)y; the precipitation order of different phases is FeO, Mn(S,O), (Si,Mn,Al)xOy and (Si,Al,Mn)xOy. (Si,Mn,Al)xOy is Mn2SiO4 with dissolved Al, while (Si,Al,Mn)xOy is Mn3Al2Si3O12 when the atomic content of Al2O3 in liquid inclusion is > 0.063.

Similar content being viewed by others

References

Y. Wang, Y. Yang, Z. Dong, J.H. Park, Z. Mi, X. Mao, and W. Mu, Metall. Mater. Trans. B 53, 2182 (2022).

L. Jin, S. Zheng, and M. Zhu, JOM (2023), published online.

C. Temmel, B. Karlsson, and N. Ingesten, Metall. and Mater. Trans. A 37, 2995 (2006).

L.E.K. Holappa, and A.S. Helle, J. Mater. Process. Tech. 53, 177 (1995).

N. Tsunekage, and H. Tsubakino, ISIJ Int. 41, 498 (2001).

T. Nishimura, S. Koishi, Y. Yamamoto, Y. Wada, K. Mine, and Y. Shinjo, Kawasaki Steel. Tech. Rep. 8, 77 (1983).

C.E. Sims, Trans. Am. Inst. Min. Metall. Eng. 215, 367 (1959).

S. Lin, H. Yang, Y. Su, K. Chang, C. Yang, S. Lin, and J. Alloy, Compd. 779, 844 (2019).

D.H. Woo, H.G. Lee, and J. Am, Ceram. Soc. 93, 2098 (2010).

Y.J. Kim, D.H. Woo, H. Gaye, H. Lee, and T. Kang, Metall. Mater. Trans. B 42, 535 (2011).

G. Wang, S. Li, X. Ai, C. Zhang, and C. Lai, J. Iron Steel Res. Int. 22, 566 (2015).

Q. Zhang, Y. Min, H. Xu, and C. Liu, ISIJ Int. 58, 1250 (2018).

Y. Ren, and L. Zhang, Ironmak. Steelmak. 46, 558 (2019).

Q. Tian, B. Liu, W. Shen, T. Hu, J. Fu, and X. Xu, Steel Res. Int. 4, 2200674 (2023).

E.T. Turkdogan, G.J.W. Kor, L.S. Darken, and R.W. Gurry, Metall. Trans. 2, 1561 (1971).

G.J.W. Kor, and E.T. Turkdogan, Metall. Trans. 3, 1269 (1972).

M. Nakamoto, T. Tanaka, M. Suzuki, K. Taguchi, Y. Tsukaguchi, and T. Yamamoto, ISIJ Int. 54, 1195 (2014).

S. Lee, and W.M. Sigmund, Colloid. Surface. A 204, 43 (2002).

W.Z. Mu, N. Dogan, and K.S. Coley, Metall. Mater. Trans. B 48, 2092 (2017).

W.Z. Mu, N. Dogan, and K.S. Coley, Metall. Mater. Trans. B 48, 2379 (2017).

O. Sudre, and F.F. Lange, J. Am. Ceram. Soc. 75, 3241 (1992).

D.A. Caillet, and D.P. Harrison, Chem. Eng. Sci. 37, 625 (1982).

F. Wakai, K. Katsura, S. Kanchika, Y. Shinoda, T. Akatsu, and K. Shinagawa, Acta Mater. 109, 292 (2016).

F. Wakai, and K.A. Brakke, Acta Mater. 59, 5379 (2011).

J. Gleinig, A. Weidner, J. Fruhstorfer, C.G. Aneziris, O. Volkova, and H. Biermann, Metall. Mater. Trans. B 50, 337 (2019).

H.S. Kim, H.G. Lee, and K.S. Oh, Metall. Mater. Trans. A 32, 1519 (2001).

J. Chen, Q. Zhu, D. Huang, S. Zheng, J. Zhang, and H. Li, IOP Conference Series: Mater. Sci. Eng. 230, 012030 (2017).

M. Wakoh, T. Sawai, and S. Mizoguchi, Tetsu-to-Hagané 78, 1697 (1992).

Y. Lu, and T. Miki, ISIJ Int. 61, 2360 (2021).

P.N. Quested, and M. McLean, Mater. Sci. Eng. 65, 171 (1984).

S. Akamatsu, and G. Faivre, Phys. Rev. E 58, 3302 (1998).

Y. Kurosaki, M. Shiozaki, K. Higashine, and M. Sumimoto, ISIJ Int. 39, 607 (1999).

Acknowledgements

The authors express their appreciation to National Natural Science Foundation of China (Grant No. 52074179) for supporting this work. One of the authors, Xiangyu Xu, gratefully acknowledges support from the National Natural Science Foundation of China (Youth Program no. 52104335) and Shanghai “Super Postdoctoral” Incentive Plan (Grant No. 2020194).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tian, Q., Shen, W., Zhang, X. et al. Formation, Aggregation, and Composite with Oxide Mechanisms of Oxysulfide in 1215MS Free-Cutting Steel. JOM 75, 5764–5772 (2023). https://doi.org/10.1007/s11837-023-06141-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06141-6