Abstract

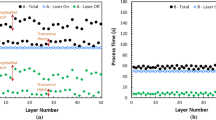

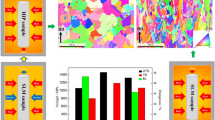

Refractory multi-principal element alloys (RMPEAs), HfNbTaTiZr, (HfNbTaTiZr)9Cr, and (HfNbTaTiZr)9Al, were manufactured using vacuum arc melting followed by laser remelting to mimic additive manufacturing. The microhardness of the as-cast HfNbTaTiZr, (HfNbTaTiZr)9Cr, and (HfNbTaTiZr)9Al samples after arc melting was measured as 6.20, 7.63, and 6.89 Gpa, respectively. After laser remelting and re-solidification, the hardness increased by ~ 30% for each composition; the hardest was (HfNbTaTiZr)9Cr measured at 9.60 GPa, while the softest was HfNbTaTiZr with a hardness of 8.42 GPa, which was still harder compared to all the other samples. The addition of Al and Cr led to enhanced oxidation resistance for the respective RMPEA systems. The Al-containing composition showed the best oxidation resistance for the samples; however, after laser remelting, the Cr-containing RMPEA had the best overall oxidation resistance, and the increase in weight after oxidation dropped by 42% when compared to that for the as-cast alloy. Laser remelting the RMPEAs led to an improvement in mechanical properties; it also resulted in enhanced oxidation resistance for (HfNbTaTiZr)9Cr. However, laser remelting barely changed the oxidation resistance for (HfNbTaTiZr)9Al, and it decreased the oxidation resistance for HfNbTaTiZr. These phenomena are related to microstructure changes induced by the laser remelting/additive manufacturing compared to conventional casting-based manufacturing.

Similar content being viewed by others

References

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Intermetallics 18, 1758 (2010).

J.P. Couzinié, G. Dirras, L. Perrière, T. Chauveau, E. Leroy, Y. Champion, and I. Guillot, Mater. Lett. 126, 285 (2014).

M. C. Gao, B. Zhang, S. Yang, and S. M. Guo, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 47, 3333 (2016).

B. Liu, J. Wang, J. Chen, Q. Fang, and Y. Liu, JOM 69, 651 (2017).

O.A. Waseem, J. Lee, H.M. Lee, and H.J. Ryu, Mater. Chem. Phys. 210, 87 (2018).

B. Kang, J. Lee, H.J. Ryu, and S.H. Hong, Mater. Sci. Eng. A 712, 616 (2018).

H. Dobbelstein, E.P. George, E.L. Gurevich, A. Kostka, A. Ostendorf, and G. Laplanche, Int. J. Extrem. Manuf. 3, 15201 (2020).

R. Wang, K. Zhang, C. Davies, and X. Wu, J. Alloys. Compd. 694, 971 (2017).

H.I. Jeong, C.M. Lee, and D.H. Kim, Mater. 15, 6570 (2022).

H. Dobbelstein, E.L. Gurevich, E.P. George, A. Ostendorf, and G. Laplanche, Addit. Manuf. 24, 386 (2018).

H. Dobbelstein, M. Thiele, E.L. Gurevich, E.P. George, and A. Ostendorf, Phys. Procedia. 83, 624 (2016).

B. Xiao, W. Jia, J. Wang, and L. Zhou, Mater. Charact. 193, 112278 (2022).

C.C. Juan, M.H. Tsai, C.W. Tsai, C.M. Lin, W.R. Wang, C.C. Yang, S.K. Chen, S.J. Lin, and J.W. Yeh, Intermetallics 62, 76 (2015).

G.V. Samsonov, Handbook of the Physicochemical Properties of the Elements (Springer, New York, NY, 2012), pp97–124.

“Periodic Table - Ptable - Properties - Electronegativity.” https://ptable.com/?lang=en#Properties/Electronegativity (accessed Apr. 20, 2023).

W. Hume-Rothery, J. Inst. Met. 35, 295 (1926).

P. Thirathipviwat, G. Song, J. Jayaraj, J. Bednarcik, H. Wendrock, T. Gemming, J. Freudenberger, K. Nielsch, and J. Han, J. Alloys. Compd. 790, 266 (2019).

P. Thirathipviwat, G. Song, J. Bednarcik, U. Kühn, T. Gemming, K. Nielsch, and J. Han, Prog. Nat. Sci. Mater. Int. 30, 545 (2020).

Q. Ding, Y. Zhang, X. Chen, X. Fu, D. Chen, S. Chen, L. Gu, F. Wei, H. Bei, Y. Gao, M. Wen, J. Li, Z. Zhang, T. Zhu, R. O. Ritchie, and Q. Yu, Nat. 574:7777 574, 223 (2019).

C. Lee, G. Song, M.C. Gao, R. Feng, P. Chen, J. Brechtl, Y. Chen, K. An, W. Guo, J.D. Poplawsky, S. Li, A.T. Samaei, W. Chen, A. Hu, H. Choo, and P.K. Liaw, Acta. Mater. 160, 158 (2018).

H. Song, F. Tian, Q.M. Hu, L. Vitos, Y. Wang, J. Shen, and N. Chen, Phys. Rev. Mater. 1, 023404 (2017).

P. Thirathipviwat, S. Sato, G. Song, J. Bednarcik, K. Nielsch, J. Jung, and J. Han, Scr. Mater. 210, 114470 (2022).

P. Thirathipviwat, S. Sato, G. Song, J. Bednarcik, K. Nielsch, and J. Han, Mater. Sci. Eng. A 823, 141775 (2021).

T. Han, Y. Liu, M. Liao, D. Yang, N. Qu, Z. Lai, and J. Zhu, J. Mater. Sci. Technol. 99, 18 (2022).

S. Zhou, Y. Xu, B. Liao, Y. Sun, X. Dai, J. Yang, and Z. Li, Opt. Laser. Technol. 103, 8 (2018).

K. Yang, J. Li, Q.Y. Wang, Z. Li, Y. Jiang, and Y. Bao, Wear 426–427, 314 (2019).

X. Yang, J. Liu, X. Cui, G. Jin, Z. Liu, Y. Chen, and X. Feng, J. Phys. Chem. Solids. 130, 210 (2019).

I. Watanabe, K. Terada, and M. Akiyama, J. Iron Steel Inst. 174, 25 (1953).

E. Hall, Proc. Phys. Soc. Sect. B 64, 747 (1951).

X.B. Feng, J.Y. Zhang, Y.Q. Wang, Z.Q. Hou, K. Wu, G. Liu, and J. Sun, Int. J. Plast. 95, 264 (2017).

H.X. Yang, J.S. Li, T. Guo, W.Y. Wang, H.C. Kou, and J. Wang, Rare Met. 39, 156 (2020).

J. Gubicza, A. Heczel, M. Kawasaki, J.K. Han, Y. Zhao, Y. Xue, S. Huang, and J.L. Lábár, J. Alloys. Compd. 788, 318 (2019).

B. Gwalani, V. Soni, M. Lee, S.A. Mantri, Y. Ren, and R. Banerjee, Mater. Des. 121, 254 (2017).

C. Yao, P. Xiaotong, G. Qunfu, W. Zhijie, and N. Pulin, Mater. Sci. Eng. A 840, 142951 (2022).

B. Xin, X. Zhou, G. Cheng, J. Yao, and Y. Gong, Opt. Laser. Technol. 127, 106087 (2020).

S. Sheikh, M.K. Bijaksana, A. Motallebzadeh, S. Shafeie, A. Lozinko, L. Gan, T.K. Tsao, U. Klement, D. Canadinc, H. Murakami, and S. Guo, Intermetallics 97, 58 (2018).

N. Yurchenko, E. Panina, S. Zherebtsov, G. Salishchev, and N. Stepanov, Mater. 11, 2526 (2018).

F. Müller, B. Gorr, H.J. Christ, J. Müller, B. Butz, H. Chen, A. Kauffmann, and M. Heilmaier, Corros. Sci. 159, 108161 (2019).

S. Yang, W. Yu, T. Liu, C. Li, Y. Zhang, and Y. Qu, Mater. Res. Express. 6, 076501 (2019).

J.D. Roach, J. Electrochem. Soc. 98, 160 (1951).

B. Sun, X. Zuo, X. Cheng, and X. Li, npj Mater. Degrad. 4, 1 (2020).

B.G. Kim, G.M. Kim, and C.J. Kim, Scr. Metall. Mater. 33, 1117 (1995).

I. Saeki, H. Konno, R. Furuichi, T. Nakamura, K. Mabuchi, and M. Itoh, Corros. Sci. 40, 191 (1998).

Z.F. Li, G.M. Cao, Y.Q. He, Z.Y. Liu, and G.D. Wang, Steel. Res. Int. 87, 1469 (2016).

R.C. Lobb and H.E. Evans, Corros. Sci. 23, 55 (1983).

G.R. Holcomb, J. Tylczak, and C. Carney, JOM 67, 2326 (2015).

Y. Zhang, H. Wu, X. Yu, and D. Tang, Corros. Sci. 200, 110211 (2022).

T. Ohmi, Y. Nakagawa, M. Nakamura, A. Ohki, and T. Koyama, J. Vac. Sci. Technol. A 14, 2505 (1996).

Y.Y. Liu, Z. Chen, Y.Z. Chen, J.C. Shi, Z.Y. Wang, S. Wang, and F. Liu, Vacuum 169, 108837 (2019).

Z.G. Zhang, X. Teng, Y.L. Mao, C.X. Cao, S.J. Wang, and L. Wang, Oxid. Met. 73, 455 (2010).

C.H. Chang, M.S. Titus, and J.W. Yeh, Adv. Eng. Mater. 20, 1700948 (2018).

R. Serrazina, J.S. Dean, I.M. Reaney, L. Pereira, P.M. Vilarinho, and A.M.O.R. Senos, J. Mater. Chem. C. 7, 14334 (2019).

N.L. Peterson, Int. Met. Rev. 28, 65 (2013).

C. Kaplin and M. Brochu, Appl. Surf. Sci. 301, 258 (2014).

L. Liu, Z. gang Yang, C. Zhang, M. Ueda, K. Kawamura, and T. Maruyama, Corros. Sci. 91, 195 (2015).

X. Wang and J.A. Szpunar, J. Alloys. Compd. 752, 40 (2018).

Acknowledgements

This research was supported by a seed grant from the Intelligent Systems Center of Missouri University of Science and Technology and by a research grant (award number 2207965) from the U.S. National Science Foundation. The Materials Research Center at Missouri University of Science and Technology is acknowledged for providing access to electron microscopy and X-ray diffraction. Dr. Eric Bohannan is thanked for his assistance with X-ray diffraction.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jalan, V., Crawford, S., Wu, SH. et al. Microstructure, Mechanical Properties and Oxidation Behavior of Refractory Multi-principal Element Alloys by Laser Remelting and Conventional Manufacturing. JOM 75, 5055–5065 (2023). https://doi.org/10.1007/s11837-023-06135-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06135-4