Abstract

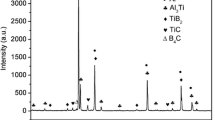

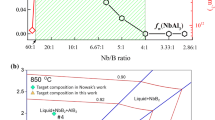

This work discloses the refinement mechanism of LaB6 in three binary aluminum alloys via grain refinement experiments, model calculation, and cooling curve analysis. The refining efficacy of LaB6 in aluminum was influenced by an interfacial relationship which can be controlled by alloying with different solute elements. Al atoms attach directly onto the surface of the LaB6 substrate during solidification. Because the lattice parameter of α-Al increased after alloying with larger metal atoms, the lattice mismatch between LaB6 and Al matrix decreased. This investigation reveals that the nucleating behavior of LaB6 can be influenced by adding solute Si, Mg, and Cu, and thereby offers a pathway for controlling the content of aluminum alloys.

Similar content being viewed by others

References

Z.N. Chen, H.J. Kang, G.H. Fan, J.H. Li, Y.P. Lu, J.C. Jie, Y.B. Zhang, T.J. Li, X.G. Jian, and T.M. Wang, Acta Mater. 120, 168 (2016).

T.E. Quested and A.L. Greer, Acta Mater. 53, 4643 (2005).

A.L. Greer, P.S. Cooper, M.W. Meredith, W. Schneider, P. Schumacher, J.A. Spittle, and A. Tronche, Adv. Eng. Mater. 5, 81 (2003).

D.H. StJohn and M.A. Easton, Alum. Cast House Technol., 151 (2001).

A. Cibula, J. Inst. Met. 76, 321 (1949).

F.A. Crossley and L.F. Mondolfo, Trans. Am. Inst. Min. Metall. Pet. Eng. 191, 1143 (1951).

M. Johnsson, L. Backerud, and G.K. Sigworth, Metall. Mater. Trans. A 24, 481 (1993).

I. Maxwell and A. Hellawell, Acta Metall. 23, 895 (1975).

M.A. Easton, M. Qian, A. Prasad, and D.H. StJohn, Curr. Opin. Solid State Mater. Sci. 20, 13 (2016).

D.H. StJohn, M. Qian, M.A. Easton, and P. Cao, Acta Mater. 59, 4907 (2011).

M.A. Easton and D.H. StJohn, Light Met., 927 (2001).

M.A. Easton and D.H. StJohn, Acta Mater. 49, 1867 (2001).

M. Easton and D. StJohn, Metall. Mater. Trans. A 30, 1613 (1999).

D.H. Stjohn, M.A. Easton, M. Qian, and J.A. Taylor, Metall. Mater. Trans. A 44A, 2935 (2013).

F. Wang, Z. Liu, D. Qiu, J.A. Taylor, M.A. Easton, and M.X. Zhanga, Acta Mater. 61, 360 (2013).

M.A. Easton, A. Prasad, and D.H. StJohn, Mater. Sci. Forum 794, 161 (2014).

L. Coudurier, N. Eustathopoulos, P. Desre, and A. Passerone, Acta Metall. 26, 465 (1978).

Paliwal and I.-H. Jung, Metall. Mater. Trans. A 44, 1636 (2013).

G.K. Sigworth, Metall. Mater. Trans. A 15, 277 (1984).

P.T. Li, S.D. Liu, L.L. Zhang, and X.F. Liu, Mater. Des. 47, 522 (2013).

P.T. Li, W.J. Tian, D. Wang, and X.F. Liu, J. Rare Earths 30, 1172 (2012).

L. Jing, Y. Pan, T. Lu, and C. Li, J. Mater. Eng. Perform. 27, 1 (2018).

P.T. Li, C. Li, J.F. Nie, J. Ouyang, and X.F. Liu, CrystEngComm 15, 411 (2013).

Y. Chen, Y. Pan, T. Lu, S.W. Tao, and J.L. Wu, Mater. Des. 64, 423 (2014).

T. Lu, Y. Pan, J.L. Wu, S.W. Tao, and Y. Chen, Int. J. Miner. Metall. Mat. 22, 405 (2015).

A.M. Mitrasinovic and F.C.R. Hernandez, Mater. Sci. Eng., A 540, 63 (2012).

M. Easton and D. StJohn, Metall. Mater. Trans. A 36A, 1911 (2005).

M. Nowak, L. Bolzoni, and N.H. Babu, Mater. Des. 66, 366 (2015).

K. Kim, Surf. Interface Anal. 47, 429 (2015).

L. Bolzoni, M. Nowak, and N.H. Babu, J. Alloys Compd. 623, 79 (2015).

M.X. Zhang, P.M. Kelly, M.A. Easton, and J.A. Taylor, Acta Mater. 53, 1427 (2005).

S.Q. Liu, X. Wang, C.X. Cui, L.C. Zhao, S.J. Liu, and C. Chen, Mater. Des. 65, 432 (2015).

J. Wang, Y. Du, S.L. Shang, Z.K. Liu, and Y.W. Li, J. Min. Metall. Sect. B-Metall. 50, 37 (2014).

A. Tonejc and A. Bonefacic, Scr. Metall. 3, 145 (1969).

A. Tonejc and A. Bonefacic, J. Appl. Phys. 40, 419 (1969).

P. Schumacher, A.L. Greer, J. Worth, P.V. Evans, M.A. Kearns, P. Fisher, and A.H. Green, Mater. Sci. Technol. 14, 394 (1998).

Z. Fan, Y. Wang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook, and T. Hashimoto, Acta Mater. 84, 292 (2015).

Acknowledgements

This research is financially supported by Jiangsu key laboratory for advanced metallic materials (BM2007204) and the Opening Project of Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology (ASMA201501). The authors thank Dr. K. Zhang and C.W Jin for their assistance with TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jing, L., Lu, T. & Pan, Y. Grain Refining Efficiency and the Role of Alloying Elements in Determining the Nucleation Potency of LaB6 in Aluminum Alloys. JOM 72, 3725–3732 (2020). https://doi.org/10.1007/s11837-019-03970-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03970-2