Abstract

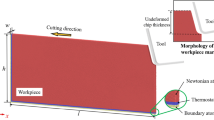

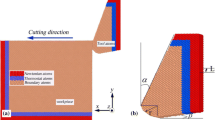

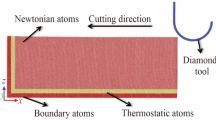

A cutting process is strongly affected by depth of cut (h0) and tool edge radius (re), the relationship of which is described by relative tool sharpness (RTS = h0/re). In nanometric cutting, the depth of cut is far smaller than the tool edge radius, thus the tool is actually a very blunt one with a highly negative effective tool rake angle (~ − 90°). However, most previous studies have assumed the tool is extremely sharp with a nanometric edge radius, and to date there is very little literature on the cutting mechanism for a blunt tool (RTS < 1). In this study, the material deformation/removal behavior and forces under a small RTS from 1 to 0 were investigated via molecular dynamics. The results show that the surface integrity and chip formation are strongly affected by RTS. As RTS is reduced to 0.25 or smaller, rubbing and ploughing occur with no material removal. In such a circumstance, the force angle drops sharply with remarkable subsurface damage formation in the workpiece. These findings are distinctly different from the common belief, and provide new information for the optimization of the silicon wafer manufacturing process.

Similar content being viewed by others

References

M. Heidari and J. Yan, Int. J. Adv. Manuf. Technol. 95, 479 (2018).

M. Mukaida and J. Yan, Int. J. Mach. Tools Manuf 115, 2 (2017).

V. Astakhop and J. C. Outeiro, in Proceedings—8th CIRP International Workshop on Modeling of Machining Operations (2005), p. 517.

X. Liu, R.E. DeVor, S.G. Kapoor, and K.F. Ehmann, J. Manuf. Sci. Eng. 126, 666 (2004).

F.Z. Fang and G.X. Zhang, Int. J. Adv. Manuf. Technol. 22, 703 (2003).

B.P. O’Connor, E.R. Marsh, and J.A. Couey, Precis. Eng. 29, 124 (2005).

M. Arif, Z. Xinquan, M. Rahman, and S. Kumar, Int. J. Mach. Tools Manuf 64, 114 (2013).

Z.J. Yuan, M. Zhou, and S. Dong, J. Mater. Process. Technol. 62, 327 (1996).

L. Zhanqiang, S. Zhenyu, and W. Yi, Int. J. Adv. Manuf. Technol. 69, 1219 (2013).

X. Wu, L. Li, M. Zhao, and N. He, Int. J. Adv. Manuf. Technol. 82, 1941 (2016).

M.A. Rahman, M.R. Amrun, M. Rahman, and A.S. Kumar, Int. J. Mach. Tools Manuf 115, 15 (2017).

M. Azizur Rahman, M. Rahman, and A. Senthil Kumar, Int. J. Adv. Manuf. Technol. 96, 3545 (2018).

J. Yan, T. Asami, H. Harada, and T. Kuriyagawa, CIRP Ann. Manuf. Technol. 61, 131 (2012).

J. Yan, H. Zhao, and T. Kuriyagawa, Semicond. Sci. Technol. 24, 75018 (2009).

D.C. Rapaport, The Art of Molecular Dynamics Simulation, 2nd ed. (Cambridge: Cambridge University Press, 2004).

R. Komanduri, N. Chandrasekaran, and L.M. Raff, Philos. Mag. Part B 79, 955 (1999).

M.B. Cai, X.P. Li, and M. Rahman, Int. J. Mach. Tools Manuf 47, 75 (2007).

A. O. Oluwajobi and X. Chen, in Proceedings of Computing and Engineering Annual Researchers’ Conference, 1997 (2010), p. 160.

F.Z. Fang, H. Wu, W. Zhou, and X.T. Hu, J. Mater. Process. Technol. 184, 407 (2007).

M. Lai, X.D. Zhang, and F.Z. Fang, Appl. Phys. A Mater. Sci. Process. 108, 809 (2012).

S. Goel, N. Haque Faisal, X. Luo, J. Yan, and A. Agrawal, J. Phys. D Appl. Phys. 47, 275304 (2014).

V.A. Balogun, I.F. Edem, A.A. Adekunle, and P.T. Mativenga, J. Clean. Prod. 116, 187 (2016).

J. Ren, Z. Dong, J. Zhao, and P. Liu, Appl. Surf. Sci. 369, 584 (2016).

J. Guénolé, A. Prakash, and E. Bitzek, Appl. Surf. Sci. 416, 86 (2017).

S. Zare Chavoshi, S. Goel, and X. Luo, J. Manuf. Process. 23, 201 (2016).

H. Zhao, C. Shi, P. Zhang, L. Zhang, H. Huang, and J. Yan, Appl. Surf. Sci. 259, 66 (2012).

J. Li, Q. Fang, L. Zhang, and Y. Liu, Appl. Surf. Sci. 324, 464 (2015).

Y. Liu, B. Li, and L. Kong, Comput. Mater. Sci. 148, 76 (2018).

J. Tersoff, Phys. Rev. B 38, 9902 (1988).

J. Tersoff, Phys. Rev. B 37, 6991 (1988).

S.V. Hosseini and M. Vahdati, Comput. Mater. Sci. 65, 29 (2012).

H. Dai, G. Chen, C. Zhou, Q. Fang, and X. Fei, Appl. Surf. Sci. 393, 405 (2017).

S. Plimpton, J. Comput. Phys. 117, 1 (1995).

A. Stukowski, Model. Simul. Mater. Sci. Eng. 18, 085001 (2010).

J. Yan, T. Asami, H. Harada, and T. Kuriyagawa, Precis. Eng. 33, 378 (2009).

J. Shimizu, H. Eda, L. Zhou, and H. Okabe, Tribol. Online 3, 248 (2008).

G. Xiao, S. To, and G. Zhang, Comput. Mater. Sci. 98, 178 (2015).

S. Venkatachalam, O. Fergani, X. Li, J. Guo Yang, K.-N. Chiang, and S.Y. Liang, J. Manuf. Sci. Eng. 137, 021020 (2015).

G. Bissacco, H.N. Hansen, and J. Slunsky, CIRP Ann. Manuf. Technol. 57, 113 (2008).

J. Yan, M. Yoshino, T. Kuriagawa, T. Shirakashi, K. Syoji, and R. Komanduri, Mater. Sci. Eng., A 297, 230 (2001).

Acknowledgements

This work was supported by the Ministry of Science, Research and Technology (MSRT) of IR Iran for international education program scholarship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ameli Kalkhoran, S.N., Vahdati, M. & Yan, J. Molecular Dynamics Investigation of Nanometric Cutting of Single-Crystal Silicon Using a Blunt Tool. JOM 71, 4296–4304 (2019). https://doi.org/10.1007/s11837-019-03671-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03671-w