Abstract

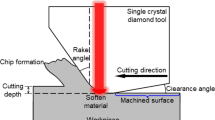

According to the hypothesis of ductile machining, brittle materials undergo a transition from brittle to ductile mode once a critical undeformed chip thickness is reached. Below this threshold, the energy required to propagate cracks is believed to be larger than the energy required for plastic deformation, so that plastic deformation is the predominant mechanism of material removal in machining these materials in this mode. An experimental study is conducted using diamond cutting for machining single crystal silicon. Analysis of the machined surfaces under a scanning electron microscope (SEM) and an atomic force microscope (AFM) identifies the brittle region and the ductile region. The study shows that the effect of the cutting edge radius possesses a critical importance in the cutting operation. Experimental results of taper cutting show a substantial difference in surface topography with diamond cutting tools of 0° rake angle and an extreme negative rake angle. Cutting with a diamond cutting tool of 0° rake angle could be in a ductile mode if the undeformed chip thickness is less than a critical value, while a ductile mode cutting using the latter tool could not be found in various undeformed chip thicknesses.

Similar content being viewed by others

References

Komanduri R, Lucca DA, Tani Y (1997) Technological advances in fine abrasive processes. Keynote Paper, Ann CIRP 46(2):545–596

Shimada S, Inamura T, Takezawa N, Ohmori H, Sata T, Ikawa N (1995) Brittle-ductile transition phenomena in microindentation and micromachining. Ann CIRP 44(1):523–526

Blackley WS, Scattergood RO (1991) Ductile regime model for diamond turning of brittle materials. Precis Eng 13(2):95–102

Shibata T, Fujii S, Makino E, Ikeda M (1996) Ductile-regime turning mechanism of single crystal silicon. Precis Eng (18)3:129–137

Lucca DA, Chou P, Hocken RJ (1998) Effect of tool edge geometry on the nanometric cutting of Ge. Ann CIRP 47(1):475–478

Komanduri R, Chandrasekaran N, Raff LM (1998) Effect of tool geometry in nanometric cutting: a molecular dynamics simulation approach. Wear 219:84–97

Fang FZ, Venkatesh VC (1998) Diamond cutting of silicon with nanometric finish. Ann CIRP 47(1):45–49

Patten J.A., Gao W (2001) Extreme negative rake angle technique for single point diamond nano-cutting of silicon. Precis Eng 25(2):165–167

Yuan ZJ, Zhou M, Dong S (1996) Effect of diamond tool sharpness on minimum cutting thickness and cutting surface integrity in ultra-precision machining. J Mater Pr 62:327–330

Kim J (1996) The influence of cutting edge radius on the machined surface of brittle materials in simulated orthogonal machining. Int J Mach 36:971–983

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, F.Z., Zhang, G.X. An experimental study of edge radius effect on cutting single crystal silicon. Int J Adv Manuf Technol 22, 703–707 (2003). https://doi.org/10.1007/s00170-003-1593-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1593-2