Abstract

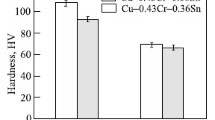

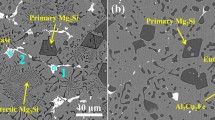

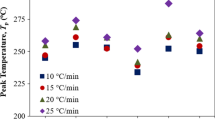

The work is devoted to studying the effect of a Sn trace addition on the precipitation hardening after aging of the eutectic Al-7 wt.% Si-7 wt.% Cu alloy. The addition of Sn and Si has a catalytic effect on the precipitation hardening and provides for a significantly higher hardness as compared with the binary Al-Cu alloy. The addition of 0.2 wt.% Sn leads to the formation of a substantially finer precipitation structure compared with the ternary alloy. As a result, the yield strength of the Sn containing alloy is up to 30% higher after uniaxial tensile tests. The finer precipitation structure of the quaternary alloy can be attributed to the higher stabilizing effect of Sn due to its partitioning in the θ″ and θ′ phases. The measured solubility of Sn (about 0.10 at.%) is close to the reported solubility of Si in θ′.

Similar content being viewed by others

Change history

21 March 2019

Torgom K. Akopyan’s name appeared incorrectly on the original published version of this article. It is corrected here.

References

I.J. Polmear, Light Metals: From Traditional Alloys to Nanocrystals, 4th ed. (Oxford: Elsevier, 2006), p. 421.

A.M. Samuel, J. Gauthier, and F.H. Samuel, Metall. Mater. Trans. A 27A, 1785 (1996).

M.V. Glazoff, A.V. Khvan, V.S. Zolotorevsky, N.A. Belov, and A.T. Dinsdale, Casting Aluminum Alloys. Their Physical and Mechanical Metallurgy (Oxford, U.K.: Elsevier, 2019), p. 564.

J.M. Silcock, T.J. Heal, and H.K. Hardy, J. Inst. Met. 82, 239 (1953–1954).

M.J. Starink and P. Van Mourik, Mater. Sci. Eng. A 156, 183 (1992).

A. Guinier, Nature 142, 569 (1938).

T.J. Konno, K. Hiraga, and M. Kawasaki, Scr. Mater. 44, 2303 (2001).

L. Bourgeois, C. Dwyer, M. Weyland, J.F. Nie, and B.C. Muddle, Acta Mater. 60, 633 (2012).

A. Rodríguez-Veiga, B. Bellon, I. Papadimitriou, G. Esteban-Manzanares, I. Sabirov, and J. LLorca, J. Alloys Compd. 757, 504 (2018).

S.K. Son, M. Takeda, M. Mitome, Y. Bando, and T. Endo, Mater. Lett. 59, 629 (2005).

L. Bourgeois, C. Dwyer, M. Weyland, J.F. Nie, and B.C. Muddle, Acta Mater. 59, 7043 (2011).

C. Wolerton and V. Ozolins, Phys. Rev. Lett. 86, 5518 (2001).

S.C. Weakley-Bollin, W. Donlon, C. Wolverton, J.W. Jones, and J.E. Allison, Metall. Mater. Trans. A 35, 2407 (2004).

D.O. Ovono, I. Guillot, and D. Massinon, Scr. Mater. 55, 259 (2006).

A. Wiengmoon, J.T.H. Pearce, T. Chairuangsri, S. Isoda, H. Saito, and H. Kurata, Micron 45, 32 (2013).

A. Biswas, D.J. Siegel, C. Wolverton, and D.N. Seidman, Acta Mater. 59, 6187 (2011).

O. Beeri, D.C. Dunand, and D.N. Seidman, Mater. Sci. Eng. A 527, 3501 (2010).

R. Sankaran and C. Laird, Mater. Sci. Eng. 14, 271 (1974).

T. Honma, D.W. Saxey, and S.P. Ringer, Mater. Sci. Forum 519–521, 203 (2006).

J.M. Silcock and H.M. Flower, Scr. Mater. 46, 389 (2002).

L. Fan, Q.T. Hao, and W.K. Han, Rare Met. 34, 308 (2015).

Y. Hu, G. Wang, M. Ye, S. Wang, L. Wang, and Y. Rong, Mater. Des. 151, 123 (2018).

Y. Zhang, Z. Zhang, N.V. Medhekar, and L. Bourgeois, Acta Mater. 141, 341 (2017).

L. Bourgeois, T. Wong, X.-Y. Xiong, J.F. Nie, and B.C. Muddle, Mater. Sci. Forum 519–521, 495 (2006).

L. Bourgeois, J.F. Nie, and B.C. Muddle, Philos. Mag. 85, 3487 (2005).

E. Holmes and B. Noble, J. Inst. Met. 95, 106 (1967).

H. Ohkubo, Y. Nagai, K. Inoue, Z. Tang, and M. Hasegawa, Mater. Sci. Forum 445, 165 (2004).

C. Wolverton, Acta Mater. 55, 5867 (2007).

M. Werinos, H. Antrekowitsch, T. Ebner, R. Prillhofer, W. Curtin, P. Uggowitzer, and S. Pogatscher, Acta Mater. 118, 296 (2016).

S.P. Ringer, K. Hono, and T. Sakurai, Met. Mater. Trans. A 26, 2207 (1995).

T. Honma, D.W. Saxey, and S.P. Ringer, Mater. Sci. Forum 519, 203 (2006).

Information on www.thermocalc.com. Accessed 20 Nov 2018.

Z. Shen, Q. Ding, C. Liu, J. Wang, H. Tian, J. Li, and Z. Zhang, J. Mater. Sci. Technol. 33, 1159 (2017).

Acknowledgements

The authors gratefully acknowledge the financial support of the Ministry of Science and Higher Education of the Russian Federation in the framework of Increase Competitiveness Program of MISiS (No. P02-2017-2-10) (experimental and computational analysis of phase equilibrium) and State Task Project No. 11.2072.2017/4.6 (preparation of alloys and analysis of precipitation structure).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article was updated to correct the spelling of Torgom K. Akopyan.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akopyan, T.K., Belov, N.A. & Letyagin, N.V. Effect of Trace Addition of Sn on the Precipitation Hardening in Al-Si-Cu Eutectic Alloy. JOM 71, 1768–1775 (2019). https://doi.org/10.1007/s11837-019-03422-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03422-x