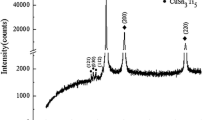

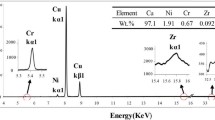

The influence of minor solute additions of Sn on hardening behavior and microstructure evolution of the Cu–Cr–Sn alloys has been investigated with help of an optical microscope, scanning electron microscope, transmission electron microscopy, and the Vickers hardness tester. Experimental results show that the Sn solutes, homogeneously distributed within the Cu matrix, provide a weak solid solution strengthening effect in the Cu–Cr–Sn alloy, nevertheless are important in enhancing precipitation hardening. The Cu–0.43Cr–0.36Sn alloy exhibits a significant age-hardening effect with a hardness increase by 62 HV after peak aging at 450°C, which is stronger than that of the Cu–0.43Cr–0.08Sn and the Cu–0.43Cr–0.17Zr–0.05Mg–0.1RE alloys. A trace amount of Sn is highly effective at suppressing the transformation of the Cr-rich phase from the face-centered cubic (FCC) into the body-centered cubic (BCC) structure in the Cu–Cr alloys during the aging process, and therefore the FCC Cr-rich precipitate is the dominant strengthening phase in the Cu–Cr–Sn alloys. Besides, a higher areal number density of Cr-rich precipitates (~4.2 · 1015 m–2) was observed in peak-aging Cu–0.43Cr–0.36Sn alloy as compared to Cu–0.43Cr–0.08Sn alloy, which shows that the adding Sn to Cu–Cr alloy can accelerate the nucleation of the Cr-rich precipitates. The improvement of precipitation hardening and hardening kinetics in the Cu–0.43Cr–0.36Sn alloy is mainly attributed to the acceleration in the nucleation of Cr-rich precipitates through Sn addition.

Similar content being viewed by others

References

Gencaga Purcek, Hilmi Yanar, Onur Saray, Ibrahim Karaman, and Hans Jürgen Maier, “Effect of precipitation on mechanical and wear properties of ultrafine-grained Cu–Cr–Zr alloy,” Wear, 311, No. 1–2. 149–158 (2014).

S. Chenna Krishna, G. Sudarsana Rao, Abhay K. Jha, Bhanu Pant, and P.V. Venkitakrishnan, “Strengthening in high strength Cu–Cr–Zr–Ti alloy plates produced by hot rolling,” Mater. Sci. Eng. A., 674, 164–170 (2016).

Ziqian Zhao, Zhu Xiao, Zhou Li, Muzhi Ma, and Jie Dai, “Effect of magnesium on microstructure and properties of Cu–Cr alloy,” J. Alloy. Compd., 752, 191–197 (2018).

A. Morozova and R. Kaibyshev, “Grain refinement and strengthening of a Cu–0.1Cr–0.06Zr alloy subjected to equal channel angular pressing,” Philos. Mag., 97, No. 24, 2053–2076 (2017).

A. Chbihi, X. Sauvage, and D. Blavette, “Atomic scale investigation of Cr precipitation in copper,” Acta Mater., 60, No. 11, 4575–4585 (2012).

M.A. Turchanin, “Phase equilibria and thermodynamics of binary copper systems with 3d-metals. III. Copper-Chromium system,” Powder Metall. Met. Ceram., 45, No. 9–10, 457–467 2006. Vol..

R. Mahmudi, A. Karsaz, A. Akbari-Fakhrabadi, and Geranmayeh Abdolreza, “Impression creep study of a Cu–0.3Cr–0.1Ag alloy,” Mater. Sci. Eng. A., 527, No. 10–11, 2702–2708 (2010).

Lijun Peng, Haofeng Xie, Guojie Huang, Gaolei Xu, Xiangqian Yin, Xue Feng, Xujun Mi, and Zhen Yang, “The phase transformation and strengthening of a Cu–0.71 wt.% Cr alloy,” J. Alloys Compd., 708, 1096–1102 (2017).

Chen Xiaobo, Jiang Feng, Lele Liu, Hongfeng Huang, and Zhangzhi Shi, “Structure and orientation relationship of new precipitates in a Cu–Cr–Zr alloy,” Mater. Sci. Tech., 34, No. 3, 282–288 (2018).

Hang Wang, Liukui Gong, Jinfa Liao, Huiming Chen, Weibin Xie, and Bin Yang, “Retaining meta-stable fcc-Cr phase by restraining nucleation of equilibrium bcc-Cr phase in CuCrZrTi alloys during ageing,” J. Alloys Compd., 749, 140–145 (2018).

C. Watanabe, R. Monzen, and K. Tazaki, “Mechanical properties of Cu–Cr system alloys with and without Zr and Ag,” J. Mater. Sci. 43, No. 3, 813–819 (2008).

S. Viorica, “Influence of thermomechanical treatment on microstructure and properties of electroslag remelted Cu–Cr–Zr alloy,” Mater. Design., 51, No. 10, P. 688–694 (2013).

Pengchao Zhang, Jinchuan Jie, Yuan Gao, Hang Li, Tongmin Wang, and Tingju Li, “Influence of cold deformation and Ti element on the microstructure and properties of Cu–Cr system alloys,” J. Mater. Res. 2015. Vol. 30, No. 13. P. 2073–2080.

Y. Pang, C.D. Xia, M.P. Wang, et al., “Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu–Cr alloy,” J. Alloys Compd., 582, No. 5, 786–792 (2014).

U. Holzwarth, H. Stamm, “The precipitation behaviour of ITER-grade Cu–Cr–Zr alloy after simulating the thermal cycle of hot isostatic pressing,” J. Nucl. Mater., 279, No. 1, 31–45 (2000).

R.K. Islamgaliev, K.M. Nesterov, J. Bourgon., et al., “Nanostructured Cu–Cr alloy with high strength and electrical conductivity,” J. Appl. Phys., 115, No. 19, 1943011–1943014 (2014).

J.H. Su, P. Liu, Q.M. Dong, et al., “Aging study of rapidly solidified and solid-solution Cu–Cr–Sn–Zn alloy,” J. Mater. Process. Tech., 205, No. 1–3, 366–369 (2008).

N. Ide, K. Hayakawa, and S. Asano, “Evaluation of microplastic flow stress in copper alloys from amplitude-dependent internal friction,” Mater. Trans., 42, No. 3, 435–438 (2015).

B. Lin, W. Zhang, Y. Zhao, and Y. Li, “Solid-state transformation of Fe-rich intermetallic phases in Al–5.0Cu–0.6Mn squeeze cast alloy with variable Fe contents during solution heat treatment,” Mater. Charact., 104, 124–134 (2013).

S. Fürtauer, D. Li, D. Cupid, H. Flandorfer, “The Cu–Sn phase diagram. Part I: New experimental results. Intermetallics,” 34, 142–147 (2013).

S.G. Mu, Y.Q. Tang, F.A. Guo, X.M. Cao, “Study on microstructure and properties of aged Cu–Cr–Zr–Mg–RE alloy,” Mater. Sci. Eng. A., 475, No. 1–2, 235–240 (2008).

X.F. Huang, W.Z. Zhang, “Improved age-hardening behavior of Mg–Sn–Mn alloy by addition of Ag and Zn,” Mater. Sci. Eng. A., 552, 211–221 (2012).

A.D. Luca, D.C. Dunand, and D.N. Seidman, “Microstructure and mechanical properties of a precipitationstrengthened Al–Zr–Sc–Er–Si alloy with a very small Sc content,” Acta Mater., 144, 80–91 (2018).

E. Gumbmann, F. De Geuser, and Ch. Sigli, “Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al–Cu–Li alloy,” Acta Mater., 133, 172–185 (2017).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Published in Poroshkova Metallurgiya, Vol. 58, Nos. 11–12 (530), pp. 45–56, 2019.

Rights and permissions

About this article

Cite this article

Luo, Z., Luo, F., Xie, W. et al. The Effect of Precipitation Characteristics on Hardening Behavior in Cu–Cr–Sn Alloy with Sn Variation. Powder Metall Met Ceram 58, 657–666 (2020). https://doi.org/10.1007/s11106-020-00122-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00122-z