Abstract

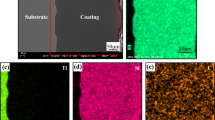

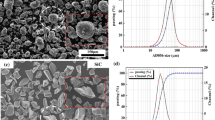

A double-layer structure of Ti coating was plated on the surface of SiC particles using a diffusion method in a vacuum reactor, which is a new method to fabricate a Ti-coating layer on the SiC particles. The phase structure of Ti coating on the surface of SiC particles was composed inside of Ti5Si3 and outside of TiC investigated by x-ray diffraction. The Ti5Si3 and TiC double-layer structure realizes the tight chemical bonding between SiC particles and the Ti coating, and significantly promotes the wettability between the aluminum matrix and the Ti-coated SiC particles. The Ti-coated SiCp-reinforced Al-Si composites are prepared by a powder metallurgy method, and express excellent relative densities, desirable mechanical properties and frictional wear resistance.

Similar content being viewed by others

References

E.K. Omyma and A. Fathy, Mater. Des. 54, 348 (2014).

Q. Liu, F. Ye, Y. Gao, S.C. Liu, H.X. Yang, and Z.Q. Zhou, J. Alloys Compd. 585, 146 (2014).

C. Aykut and V. Temel, Powder Technol. 26, 348 (2014).

Y.S. Su, Q.B. Ouyang, W.L. Zhang, Z.Q. Li, Q. Guo, G.L. Fan, and D. Zhang, Mater. Sci. Eng. A 597, 359 (2014).

A. Mahato, S. Xia, T. Perry, A. Sachdev, and S.K. Biswas, Tribol. Int. 43, 381 (2010).

Y.S. Suh, S.P. Joshi, and K.T. Ramesh, Actar Mater. 57, 5848 (2009).

X. Kai, Z. Li, G. Fan, Q. Guo, D.B. Xiong, W. Zhang, Y. Su, W. Lu, W.J. Moon, and D. Zhang, Mater. Sci. Eng. A 587, 46 (2013).

B.W. Xiong, Z.F. Xu, Q.S. Yan, B.P. Lu, and C.C. Cai, J. Alloys Compd. 509, 1187 (2010).

T. Ozben, E. Kilickap, and O. Cakir, J. Mater. Process. Technol. 198, 220 (2008).

Z. Wang, M. Song, C. Sun, D. Xiao, and Y. He, Mater. Sci. Eng. A 527, 6537 (2010).

J.Y. Song, G. Qiang, O.Y. Qiubao, Y.S. Su, and J. Zhang, Mater. Sci. Eng. A 644, 79 (2015).

J.H. Nie, J.Z. Fan, and S.M. Zhang, Acta Metall. Sinica 27, 875 (2014).

M. Song and Y.H. He, Mater. Des. 31, 9859 (2010).

J. Tian, E. Pinero, J. Narciso, and E. Louis, Scr. Mater. 53, 1483 (2005).

Z.P. Luo, Acta Mater. 54, 47 (2006).

X.S. Cong, P. Shen, Y. Wang, and Q.C. Jiang, Appl. Surf. Sci. 317, 140 (2014).

L.J. Zhang, D.L. Yang, F. Qiu, J.G. Wang, and Q.C. Jiang, Mater. Sci. Eng. A 624, 102 (2015).

S.C. Kim, M.T. Kim, S. Lee, and H. Chung, J. Mater. Sci. 40, 441 (2005).

C.A. Leon and R.A.L. Drew, Compos. Part A 33, 1429 (2002).

S.L. Zhu, L. Tang, Z.D. Cui, Q. Wei, and X.J. Yang, Surf. Coat. Technol. 205, 2985 (2011).

J.C. Lee, J.P. Ahn, Z. Shi, Y. Kim, and H.I. Lee, Metall. Mater. Trans. A 31, 2361 (2000).

J.K. Li, L. Liu, Y.T. Wu, and Z.B. Li, Surf. Coat. Technol. 180, 575 (2011).

S.S. Wu, Y. You, P. An, T. Kanno, and H. Nakae, J. Mater. Sci. 37, 1855 (2002).

M. Zha, H.Y. Wang, S.T. Li, S.L. Li, Q.L. Guan, and Q.C. Jiang, Mater. Chem. Phys. 114, 709 (2009).

M. Nakae, J.C. Feng, and J.C. Schuster, Metall. Mater. Trans. A 28, 1385 (1997).

D.L. Yang, F. Qiu, W.X. Zhao, P. Shen, H.Y. Wang, and Q.C. Jiang, Mater. Des. 87, 1100 (2015).

D.L. Yang, F. Qiu, Z.K. Lei, Q.L. Zhao, and Q.C. Jiang, Mater. Sci. Eng. A 661, 217 (2016).

B.J. Kooi, M. Kabel, A.B. Kloosterman, and D.H. JTM, Acta Mater. 47, 3105 (1999).

Y.H. Wang, X.H. Zhang, J.B. Zang, E.B. Ge, J.H. Zhang, and X.Z. Cheng, Surf. Coat. Technol. 205, 4627 (2011).

Acknowledgements

This work was supported by Science and Technology Plan Projects of Hunan Province (No. 2015JC3004) and Natural Science Foundation of Hunan Province (No. 2016JJ2147).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Y., Ren, J., Dong, C. et al. Microstructures and Properties of Ti-Coated SiCp Reinforced Al-Si Alloy Composites. JOM 69, 756–762 (2017). https://doi.org/10.1007/s11837-016-2233-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2233-2