Abstract

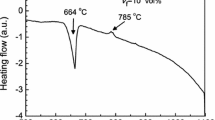

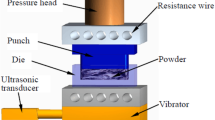

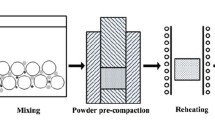

Composite materials based on alloys of the Al–Si–Mg system have been obtained via the introduction of 5, 10, and 15 wt % of SiC particles into the alloy melt and the solidification under a pressure. As a result of solidification under pressure, the porosity of the composite materials decreased substantially. An increase in the content of SiC particles in the composites enabled a smaller size of dendritic cells to be obtained. It has been shown by the X-ray diffraction method that, in the process of solidification under pressure, an interaction occurred between the matrix and reinforcing SiC particles. The presence of SiC particles in the structure of composites led to the acceleration of the aging process and to an increase in the peak hardness in comparison with the matrix alloy.

Similar content being viewed by others

References

M. T. El-Hair, “Microstructure characterization and tensile properties of squeeze-cast Al–Si–Mg alloys,” Mater. Lett. 59, 894–900 (2005).

O. Beffort, S. Long, C. Cayron, J. Kuebler, and A. Buffat, “Alloying effects on microstructure and mechanical properties of high volume fraction SiC-particle reinforced Al–MMCs made by squeeze casting infiltration,” Comp. Sci. Tech. 67, 737–745 (2007).

M. T. El-Hair, A. Lotfy, A. Daoud, and A. M. El-Sheih, “Microstructure, thermal behavior and mechanical properties of squeeze cast SiC, ZrO2 or C reinforced ZA27 composites,” Mater. Sci. Eng., A 528, 2353–2362 (2011).

A. Yu. Churyumov, A. I. Bazlov, A. N. Solonin, V. Yu. Zadorozhnyi, G. Q. Xie, S. Li, and D. V. Louzguine-Luzgin, “Structure and mechanical properties of Ni–Cu–Ti–Zr composite materials with amorphous phase,” Phys. Met. Metallogr. 114, 773–778 (2013).

A. I. Bazlov, A. Yu. Churyumov, and A. A. Tsarkov, “Studies of the structure and mechanical properties of Ti43.2Zr7.8Cu40.8Ni7.2Co1 alloy containing amorphous and crystalline phases,” Phys. Met. Metallogr. 116, 684–689 (2015).

M. Aydin, R. Gürler, and M. Türker, “The diffusion welding of 7075Al–3% SiC particles reinforced composites,” Phys. Met. Metallogr. 107, 206–210 (2009).

V. I. Kuz’min, V. I. Lysak, S. V. Kuz’min, and V. O. Kharlamov, “Effect of heat treatment on the structure and properties of steel–aluminum composite with a diffusion barrier,” Phys. Met. Metallogr. 116, 1096–1102 (2015).

V. A. Popov and V. V. Cherdyntsev, “Formation of a nanodispersed metal-matrix structure during a combined high-energy mechanical alloying of powders of aluminum-based SiC-containing alloys,” Phys. Met. Metallogr. 107, 45–52 (2009).

A. V. Pozdniakov, A. Lotfy, A. Qadir, and V. S. Zolotorevskiy, Influence of B4C on the structure and coefficient of thermal expansion of the metal matrix composite material based alloy Al-5% Cu,” Phys. Met. Metallogr. 117, (in press) 2016.

G. Ranganath, S. C. Sharma, M. Krishna, and M. S. Muruli, “A study of mechanical properties and fractography of ZA-27/titanium-dioxide metal matrix composite,” J. Mater. Eng. Perform. 11, 408–413 (2002).

K. H. Seah, S. C. Sharma, and B. M. Grish, “Mechanical properties of as-cast and heat-treated ZA-27/graphite particulate composites,” Comp. A: Appl. Sci. Manufac. 28, 251–256 (1997).

X. Fan, X. Yin, X. Cao, L. Chen, L. Cheng, and L. Zhang, “Improvement of the mechanical and thermophysical properties of C/SiC composites fabricated by liquid silicon infiltration,” Comp. Sci. Tech. 115, 21–27 (2015).

P. K. Rohatgi, S. Alaraj, R. B. Thakkar, and A. Daoud, “Variation in fatigue properties of cast A359–SiC composites under total strain controlled conditions: Effects of porosity and inclusions,” Comp. A: Appl. Sci. Manufac. 38, 1829–1841 (2007).

M. Kok and K. Ozdin, “Wear resistance of aluminum alloy and its composites reinforced by Al2O3 particles,” J. Mater. Proces. Techn. 183, 301–309 (2007).

P. Poddar, V. C. Srivastava, P. K. De, and K. L. Sahoo, “Processing and mechanical properties of SiC reinforced cast magnesium matrix composites by stir casting process,” Mater. Sci. Eng., A 460–461, 357–364 (2007).

L. J. Yang, “The effect of solidification time in squeeze casting of aluminum and zinc alloys,” J. Mater. Process Techn. 192–193, 114–120 (2007).

M. Schöbel, W. Altendorfer, H. P. Degischer, S. Vaucher, T. Buslaps, M. Michiel, and M. Hofmann, “Internal stresses and voids in SiC particle reinforced aluminum composites for heat sink applications,” Comp. Sci. Techn. 71, 724–733 (2011).

R. S. M. Seyed, “Processing of squeeze cast Al6061–30 vol % SiC composites and their characterization,” Mater. Design 27, 216–222 (2006).

M. T. El-Khair, “Microstructure characterization and tensile properties of squeeze-cast AlSiMg alloys,” Mater. Lett. 59, 894–900 (2005).

A. Daoud, “Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration,” Mater. Sci. Eng., A 391, 114–120 (2005).

M. Kok, “Production and mechanical properties of Al2O3 particle reinforced 2024 aluminum alloy composites,” J. Mater. Process. Technol. 161, 381–387 (2005).

H. Young and G. Chung, “The effect of applied pressure on particle—Dispersion characteristics and mechanical properties in melt-stirring squeeze cast SiC/Al composites,” J. Mater. Process. Technol. 55, 370–379 (1995).

B. Li, B. Luo, K. He, L. Zeng, W. Fan, and Z. Bai, “Effect of aging on interface characteristics of Al–Mg–Si/SiC composites,” J. Alloys Compd. 649, 495–499 (2015).

H. Liao, Y. Wu, and K. Ding, “Hardening response and precipitation behavior of Al–7% Si–0.3% Mg alloy in a pre-aging process,” Mater. Sci. Eng., A 560, 811–816 (2013).

R. Dong, W. Yang, Z. Yu, P. Wu, M. Hussain, L. Jiang, and G. Wu, “Aging behavior of 6061Al matrix composite reinforced with high content SiC nanowires,” J. Alloys Compd. 649, 1037–1042 (2015).

J. Banhart, C. S. T. Chang, Z. Q. Liang, N. Wanderka, M. D. H. Lay, and A. J. Hill, “Natural aging in Al–Mg–Si alloys—A process of unexpected complexity,” Adv. Eng. Mater. 12, 559–571 (2010).

M. R. Gazizov, A. V. Dubina, D. A. Zhemchuzhnikova, and R. O. Kaibyshev, “Effect of equal-channel angular pressing and aging on the microstructure and mechanical properties of an Al–Cu–Mg–Si alloy,” Phys. Met. Metallogr. 116, 718–729 (2015).

I. Dutta, S. M. Allen, and J. L. Hafley, “Effect of reinforcement on the aging response of cast 6061–Al2O3 particulate composite,” Metall. Trans. A 22, 2553–2563 (1992).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.A. Mohamed, A.Yu. Churyumov, 2016, published in Fizika Metallov i Metallovedenie, 2016, Vol. 117, No. 10, pp. 1089–1095.

Rights and permissions

About this article

Cite this article

Mohamed, E.A., Churyumov, A.Y. Investigation of the microstructure and properties of Al–Si–Mg/SiC composite materials produced by solidification under pressure. Phys. Metals Metallogr. 117, 1054–1060 (2016). https://doi.org/10.1134/S0031918X16100070

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X16100070