Abstract

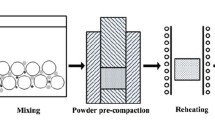

The effect of copper addition on powder processed Al-10 vol% SiC composites was studied in regards to their sintering responses. Copper was mixed with aluminum powder either as elemental powders or as the coated layer on SiC particles. After sintering at 600°C for 1 h, Al-SiC composites with no copper addition showed little densification. It also demonstrated very low bend strengths of 49 and 60 MPa, indicating poor bonding between the powders in the sintered composite. The addition of 8% copper to the Al/SiC system effectively improved the sintering response, producing over 95% theoretical density, a bend strength of 231 MPa with the copper coated SiC, and a 90% density with over 200 MPa bend strength with the admixed copper.

The as-sintered microstructures of the Al–SiC composites clearly revealed particle boundaries and sharp pores, indicating that only a limited neck growth occurred during sintering. In the case of Al–Cu–SiC composites, however, a liquid phase was formed and spread through particle boundaries filling the interfaces or voids between SiC particles and the matrix powders. The coated copper on SiC particles produced a somewhat better filling of the interface or voids, resulting in a little more densification and better sintered strength. Since the solubility of copper in aluminum is less than 2% at the sintering temperature, the alloying of copper in the aluminum matrix was limited. Most of the copper added was dissolved in the liquid phase during the sintering and precipitated as CuAl2 phase upon cooling.

Similar content being viewed by others

References

N. V. Ravi Kumar and E. S. Dwarakadasa, Composites, Part A 31 (2000) 1139.

C. Srinivasa Rao and G. S. Upadhyaya, Mater. Design 16 (1995) 359.

B. G. Kim, S. L. Dong and S. D. Park, Mater. Chem. Phys. 72 (2001) 42.

I. Ozdemir, U. Cocen and K. Onel, Comp. Sci. Techn. 60 (2000) 411.

J.-C. Lee, J.-Y. Byun, C.-S. Oh, H.-K. Seok and H.-I. Lee, Acta Mater. 45 (1997) 5303.

A. M. Davidson and D. Regener, Comp. Sci. Techn. 60 (2000) 865.

L. M. Tham, M. Gupta and L. Cheng, Acta Mater. 49 (2001) 3243.

B. Ogel and R. Gurbuz, Mater. Sci. Engng. A 301 (2001) 213.

M. Gupta, M. K. Surappa and S. Qin, J. Mater. Proc. Techn. 67 (1997) 94.

S. K. Takur and B. K. Dhindaw, Wear 247 (2001) 191.

C. A. Leon and R. A. L. Drew, J. Mater. Sci. 35 (2000) 4763.

W. S. Chung, S. Y. Chang and S. J. Lin, Plat. Surf. Finish. 83 (1996) 68.

G. B. Schaffer, T. B. Sercombe and R. N. Lumley, Mater. Chem. Phys. 67 (2001) 85.

C. Hu and T. N. Baker, Mater. Sci. Engng. A 190 (1995) 125.

“Alloy Phase Diagrams, ASM Handbook” (ASM International, Materials Park, OH, 1992) Vol. 3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, SC., Kim, MT., Lee, S. et al. Effects of copper addition on the sintering behavior and mechanical properties of powder processed Al/SiC p composites. J Mater Sci 40, 441–447 (2005). https://doi.org/10.1007/s10853-005-6101-7

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6101-7