Abstract

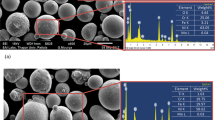

The present paper investigated and analyzed swirler material consisting of mild steel which was subjected to service for the period of one year in a 30 MW marine boiler. Due to the presence of high temperatures in the furnace coupled with the corrosive marine environment swirler material showed accelerated degradation and material wastage. An investigation into the feasibility of manufacturing the existing swirler with an alternate material or coating the swirler material with a thermal barrier coating was undertaken. Based on their properties and performance, SS 304 and SS 316 were proposed as the replacement materials for the swirler. The other alternative of coating the existing swirlers with a form thermal barrier coating to observe for any improvement in their performance at elevated temperatures was also tested. Stellite, which is a Ni-Co based coating, was carried out on the MS samples and the same were exposed to same temperatures mentioned above. The performance of the available options was evaluated with respect to the grain structure of the material, the hardness value of the materials and deterioration at elevated temperatures. Investigation showed the proposed materials/coatings like SS 304, SS 316 and Stellite coating revealed that SS 316 is the material best suited for high temperature application.

Similar content being viewed by others

References

ASTM Designation E-112-96, 2004. Standard test methods for determining average grain size. American Society for Testing and Materials.

Atanda P, Fatudimu A, Oluwole O, 2010. Sensitisation study of normalised 316L stainless steel. Minerals and Materials Characterisation & Engineering, 9(1), 13–23.

Castrejon J, Serna S, Wong-Moreno A, Fragiel A, López-López D, 2006. Study of the degradation of power generation combustion components at elevated temperatures. Materials Science and Engineering, A 415, 118–125. DOI:10.1016/j.msea.2005.09.080

Chaudhari S, 1994. Heat treatment of stainless steels. National Metallurgical Laboratory, Jamshedpur.

Fauchais P, Vardelle A, 2012. Thermal sprayed coatings used against corrosion and corrosive wear. In: Hamidreza Salimi Jazi “Advanced plasma spray applications”, ISBN 978-953-51-0349-3, 250 pages, Publisher: InTech. DOI: 10.5772/34448

López-López D, Castrejon J, Wong-Moreno A, Campllio B, Martinez L, 1999. High temperature corrosion of fuel oil burner components. Nace Annual Corrosion Conference, Denver, USA, Paper-99071.

López-López D, Wong-Moreno A, Martinez L, 2002. Carburisation in fossil fuelled boilers-A review. Nace Annual Corrosion Conference, Huston, USA, Paper-02378.

Metals Handbook, 9th ed, 1987. Elevated-temperature failures, vol. 11. ASM International, 1987, 263–277.

Pickering FB, 1976. Physical metallurgy of stainless steel developments. International Metals Review, Review 211.

Priss J, Klevtsov I, Dedov A, Antonov M, 2014. Investigation of boiler materials with relation to corrosion and wear: review. 9th International DAAAM Baltic Conference “INDUSTRIAL ENGINEERING”, Tallinn, Estonia.

Virdi RS, Thakur DG, 2015. Study of high temperature corrosion and degradation of boiler combustion components. International Conference on Recent Advances in Mechanical Engineering(ICRAME)-2015, Pune, India, Paper-OEM 12. DOI: dx.doi.org/10.4236/jmmce.2010.91002

Wong-Moreno A, Lopez-Lopez D, Martinez L, 2002. High temperature corrosion mechanisms by combustion products of heavy high sulphur fuel oils. An extension of the wilson model. Corrosion, Paper No 02374.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Virdi, R.S., Thakur, D.G. Investigation and analysis of high temperature corrosion and degradation of marine boiler combustion swirler. J. Marine. Sci. Appl. 15, 86–94 (2016). https://doi.org/10.1007/s11804-016-1347-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11804-016-1347-9